Method for processing fast cooking edible husked rice and edible husked rice maded thereout

A processing method and technology for brown rice, applied in food preparation, application, food science and other directions, can solve the problems of waste of nutrient resources, lost nutrition and health, etc., and achieve the effect of improving taste and ensuring nutritional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

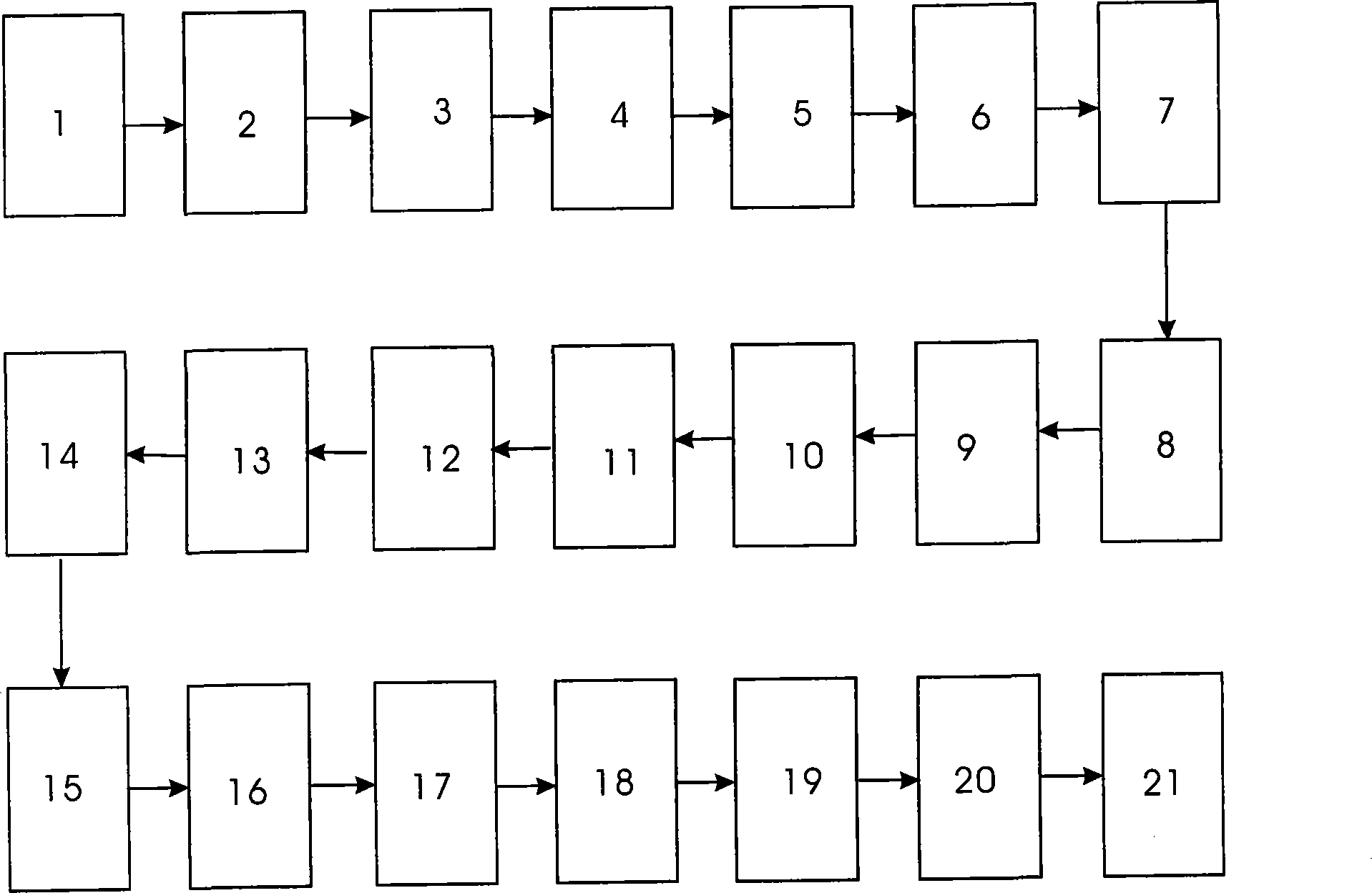

Image

Examples

Embodiment 1

[0023] After the rice is dried in the drying tower, it is stored in a low-temperature constant temperature storage. Then the rice is removed from impurities, cleaned, stone removed, shelled, lightly milled by a vertical rice mill, polished and color sorted into brown rice as raw material, and the brown rice is washed with water After rinsing and draining, add compound enzyme solution at a ratio of 1:2, and soak the brown rice mixture in an ultrasonic field (25W, 30KHz) for 2 hours at a temperature of 30°C. After adjusting the soaking liquid to be neutral, enter the continuous cooking machine and steam cook for 25 minutes at a temperature of 90°C. Enter the circulating ventilation continuous drying machine again, dry 6 hours at 50 ℃ of temperature, make the brown rice that moisture content is 13%. The dried brown rice enters the microwave for sterilization. The automatic electronic packaging scale divides the brown rice into bags. The cooking time of brown rice is short, the ...

Embodiment 2

[0025] After the rice is dried in the drying tower, it is stored in a low-temperature constant temperature storage. Then the rice is removed from impurities, cleaned, stone removed, shelled, lightly milled by a vertical rice mill, polished and color sorted into brown rice as raw material, and the brown rice is washed with water After rinsing and draining, add compound enzyme liquid at a ratio of 1:5, and soak the above brown rice mixture in an ultrasonic field (25W, 30KHz) for 4 hours at a temperature of 26°C. After adjusting the soaking liquid to be neutral, enter the continuous cooking machine and steam cook for 45 minutes at a temperature of 110°C. Enter the circulation ventilation continuous drying machine again, dry 4 hours at 60 ℃ of temperature, make the brown rice that moisture content is 12%. The dried brown rice enters the microwave for sterilization. The finished product of brown rice is obtained by automatic electronic packaging scale. The cooking time of brown r...

Embodiment 3

[0027] After the rice is dried in the drying tower, it is stored in a low-temperature constant temperature storage. Then the rice is removed from impurities, cleaned, stone removed, shelled, lightly milled by a vertical rice mill, polished and color sorted into brown rice as raw material, and the brown rice is washed with water After rinsing and draining, add compound enzyme solution at a ratio of 1:3, and soak the brown rice mixture in an ultrasonic field (25W, 30KHz) for 2.5 hours at a temperature of 30°C. After adjusting the soaking liquid to be neutral, enter the continuous cooking machine and steam cook for 30 minutes at a temperature of 110°C. Enter the circulation ventilation continuous drying machine again, dry 4 hours at 60 ℃ of temperature, make the brown rice that moisture content is 12%. The dried brown rice enters the microwave for sterilization. The finished product of brown rice is obtained by automatic electronic packaging scale. The taste of brown rice is so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com