Rice fine-processing technique

A rice and craft technology, applied in the direction of combination device, application, sorting, etc., can solve the problems of many broken rice grains, poor surface finish of rice, and uneven size of rice grains, so as to reduce broken rice grains, reduce waste of food resources, and improve grain quality. The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

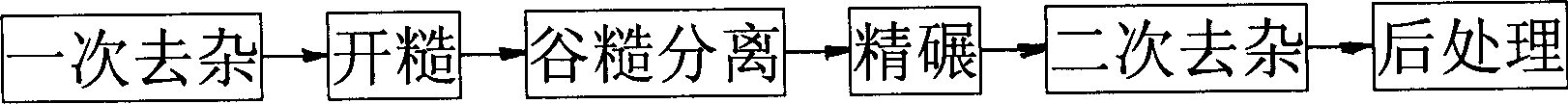

[0016] Such as figure 1 As shown, a rice finishing process adopts the following process steps: first impurity removal - roughness breaking - paddy separation - fine milling - second impurity removal - post-treatment.

[0017] One-time impurity removal is the cleaning of organic impurities. The specific gravity de-stoner machine is used to remove the mud, stone sand and barnyard grains in the rice through multiple filtrations of the sieve.

[0018] The roughening adopts the wet roughening technology. Rice processing technology is the key technology to improve brown rice yield and reduce broken rice. In the rice finishing process, in addition to using a ceramic roller rice mill, the wetting and roughening technology is adopted, that is, according to the moisture content of the rough rice, add different degrees of water, and atomize it into a mist to make it Contact with the surface of the rough rice, when the surface of the rough rice is in instant contact with the rotating ce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com