Co-production machining method of germ-remaining rice and multi-grade rice

A multi-grade technology with retained embryos, applied in the field of grain processing, can solve problems that are not conducive to the flexible production of various raw grains, achieve flexible and accurate product sorting, ensure product purity, and increase the retention rate of rice embryos.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

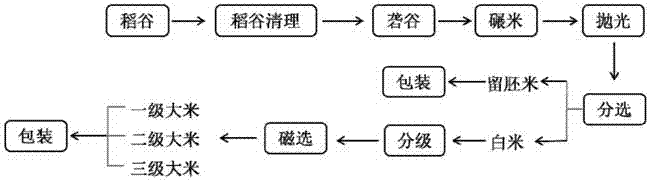

[0037] Embodiment 1: a kind of method for the coproduction processing of leaving germ rice and multi-grade rice, comprises the following steps:

[0038] (1) paddy is cleaned, hulled (hulled) and made into brown rice;

[0039] (2) Rice milling

[0040] The brown rice is lightly milled with multiple machines using an emery roller rice mill. 2-3 rice mills are used in series, the particle size of emery rollers is 46 (425-355 / μm), 46 (425-355 / μm), 60 (355-250 / μm) mesh respectively, and the speed of emery rollers is 940r / min, 880r / min, 840r / min.

[0041] (3) Sorting

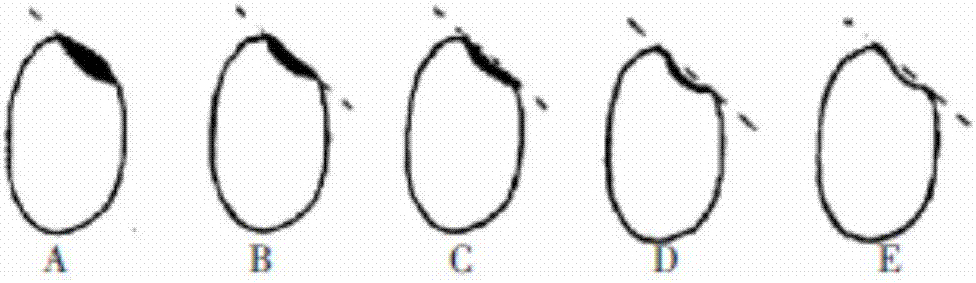

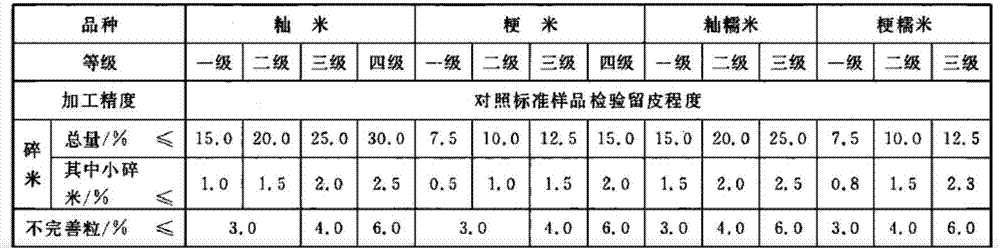

[0042] Extract the appearance feature parameters of the rice image through the color sorter, judge the shape and color of the rice grains, and eliminate the endosperm that is yellow and in D 65Yellow-grained rice whose chromaticity index b* value is equal to or greater than 7 under the 10° field of view of the illuminating body, and separated to obtain embryonic rice and white rice. At the same time, the project...

Embodiment 2

[0046] Embodiment 2: a kind of method for the coproduction processing of leaving germ rice and multi-grade rice, comprises the following steps:

[0047] (1) Cleaning up japonica rice, hulling (husking) and making brown rice;

[0048] (2) Rice milling

[0049] The brown rice is lightly milled with multiple machines using an emery roller rice mill. 2-4 sets of rice mills are used in series, the particle size of emery rollers is 36 (600-500 / μm), 46 (425-355 / μm), 60 (355-250 / μm) mesh, and the speed of emery rollers is 1040r / min, 940r / min, 840r / min.

[0050] (3) Sorting

[0051] Extract the appearance feature parameters of the rice image through the color sorter, judge the shape and color of the rice grains, and eliminate the endosperm that is yellow and in D 65 The yellow-grained rice whose chromaticity index b* value is equal to or greater than 7 under the 10° field of view of the illuminating body is separated to obtain white rice. Working conditions of color sorter: air s...

Embodiment 3

[0056] Embodiment 3: a kind of method for co-production processing of remaining germ rice and multi-grade rice comprises the following steps:

[0057] (1) Cleaning up japonica rice, hulling (husking) and making brown rice;

[0058] (2) Rice milling

[0059] The brown rice is lightly milled with multiple machines using an emery roller rice mill. 3-4 rice mills are used in series, the particle size of the emery rollers is 36 (600-500 / μm), 46 (425-355 / μm), 60 (355-250 / μm) mesh, and the rotation speed of the emery rollers is 1040r / min, 940r / min, 840r / min.

[0060] (3) Sorting

[0061] Extract the appearance feature parameters of the rice image through the color sorter, judge the shape and color of the rice grains, and eliminate the endosperm that is yellow and in D 65 Yellow-grained rice whose chromaticity index b* value is equal to or greater than 7 under the 10° field of view of the illuminating body, and separated to obtain embryonic rice and white rice. At the same time,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com