Secondary smelting method for producing magnesium-zirconium intermediate alloy

A magnesium-zirconium master alloy and secondary smelting technology, which is applied in the production field of magnesium-zirconium master alloy, can solve the problems of high alloy impurity content, difficult quality control, and high alloy impurity, and achieve high effective content, good uniformity, and low impurity content. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

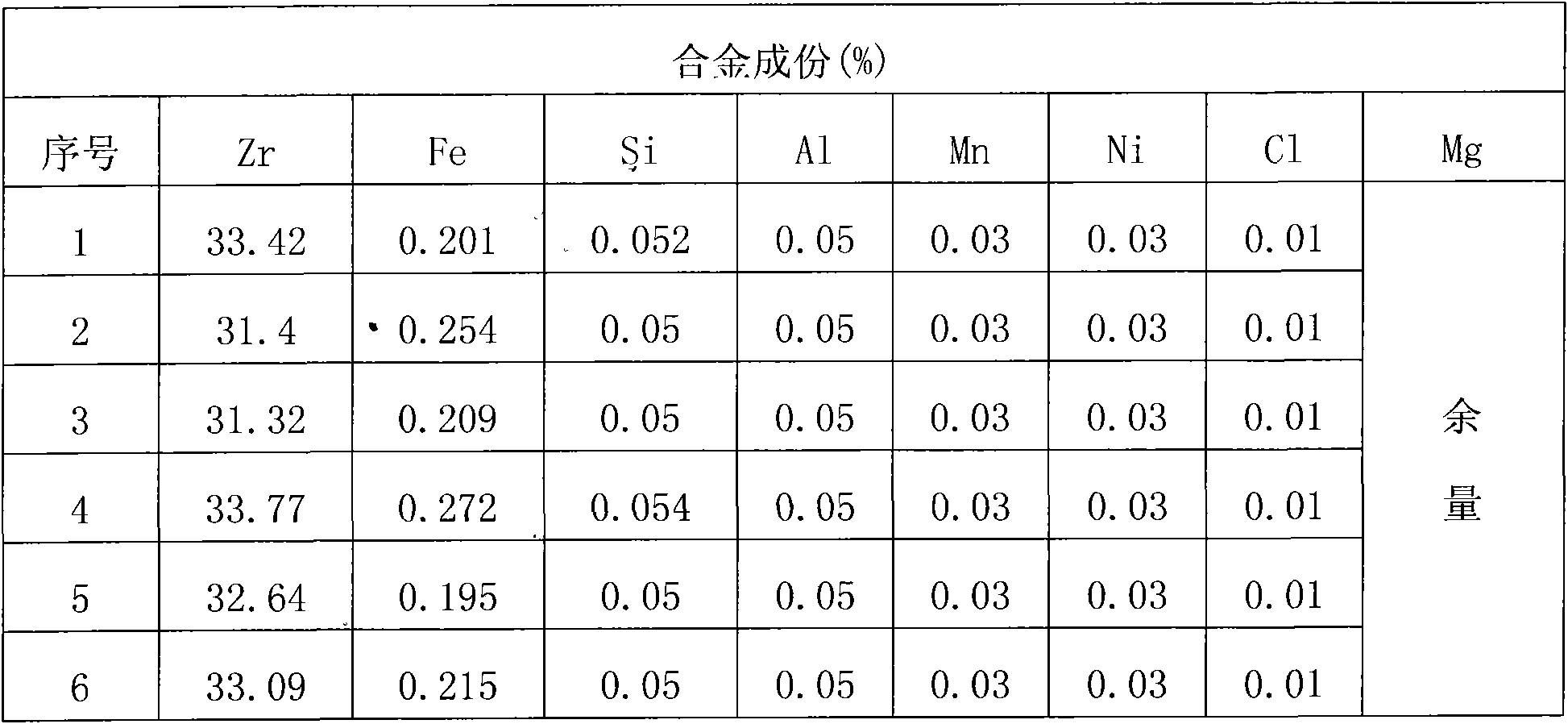

Embodiment 1

[0022] The 1st, 2nd, 4th, 5th, 6th, and 7th processes in the production steps of this example are the same as above, but the 3rd rough refining process is as follows: add 150kg potassium chloride to the steel pot, and heat up to 880 within 25 to 30 minutes. ~910°C. After the potassium chloride is completely melted, slag removal is carried out. After the slag removal, 130 kg of potassium zirconium fluoride is added while stirring with a mechanical nickel rod. The addition time is 10 to 30 minutes. The slag was removed for the second time, and 100kg of magnesium was added thereafter. When the magnesium is completely melted at a furnace temperature of 880-910°C, sprinkle protective flux, the amount of which is limited to the extent that the melt can be extinguished in time, and stir with a mechanical nickel rod for 10-20 minutes at the same time, then lift the steel pot out .

Embodiment 2

[0024] This example is basically the same as Example One, except that the addition of magnesium is 108.3kg.

Embodiment 3

[0026] This example is basically the same as Example One, except that the addition of magnesium is 86.7kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com