Multi-stage catalyzed sorption reactor

A reactor and adsorption bed technology, which is applied in the field of reaction devices for catalytic adsorption of sulfur, can solve problems such as unfavorable industrial production development, tail gas failure to meet standards, complicated process, etc., to reduce tail gas treatment investment, fast consumption, and broad market prospects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

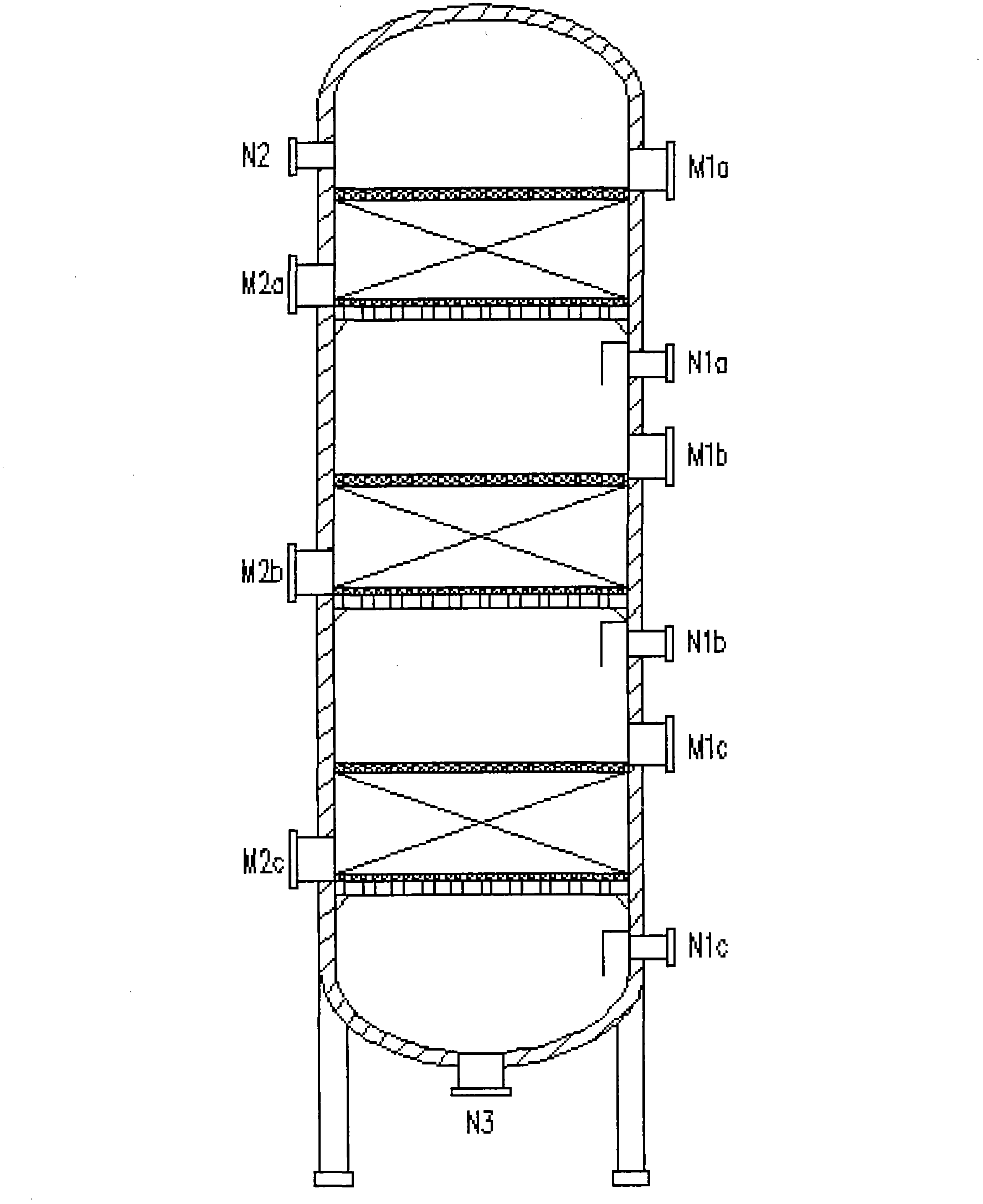

[0010] Embodiment 1: as shown in Figure 1, the present invention comprises: reactor body 1, three catalytic adsorption beds C1, C2 and C3, charging port M1a, M1b and M1c, discharge port M2a, M2b and M2c, inlet Gas ports N1a, N1b and N1c, gas outlet N2 and sewage outlet N3, the three catalytic adsorption beds are fixed inside the reactor body 1, and the interior of the reactor body 1 is divided into four independent catalytic adsorption spaces; The discharge port M2a and the charging port M1a are arranged on the upper surface of the reactor body 1 close to the catalytic adsorption bed layer C1, the discharge port M2b and the charging port M1b are arranged on the upper surface of the reactor body 1 near the catalytic adsorption bed layer C2, and the reactor body 1 is close to The upper surface of the catalytic adsorption bed C3 is provided with a discharge port M2c and a charging port M1c; the air inlet N1a is arranged on the reactor body 1 on the lower surface of the catalytic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com