Patents

Literature

30results about How to "Small processing investment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

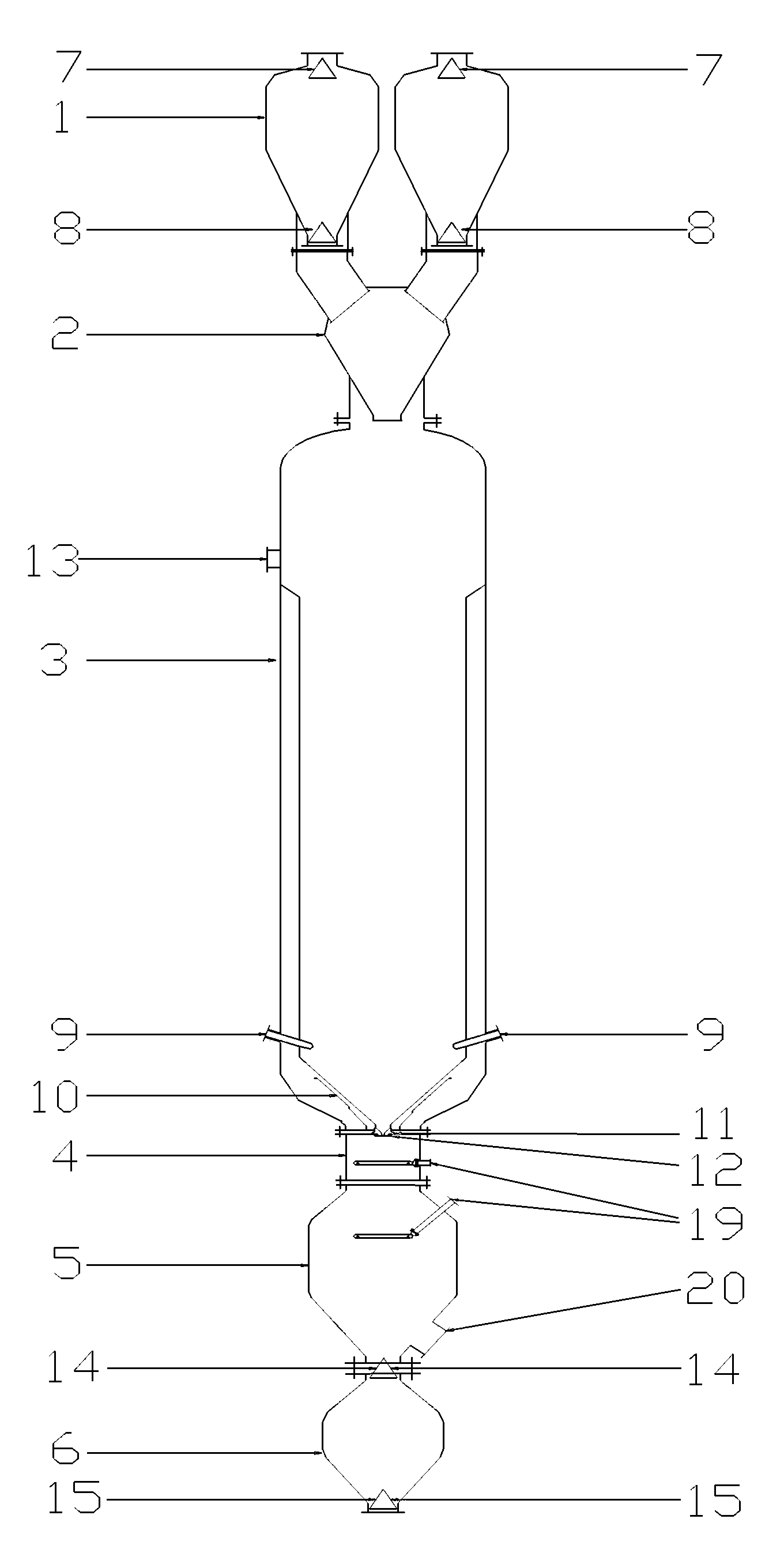

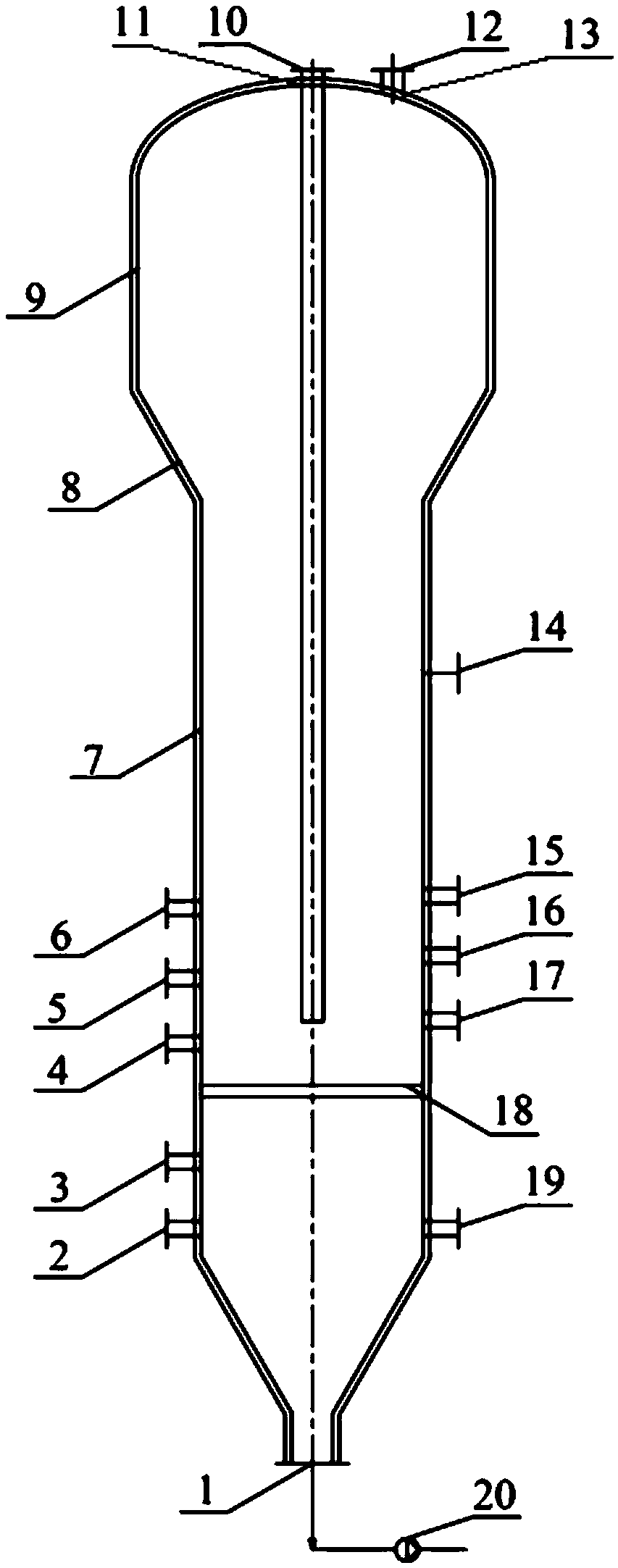

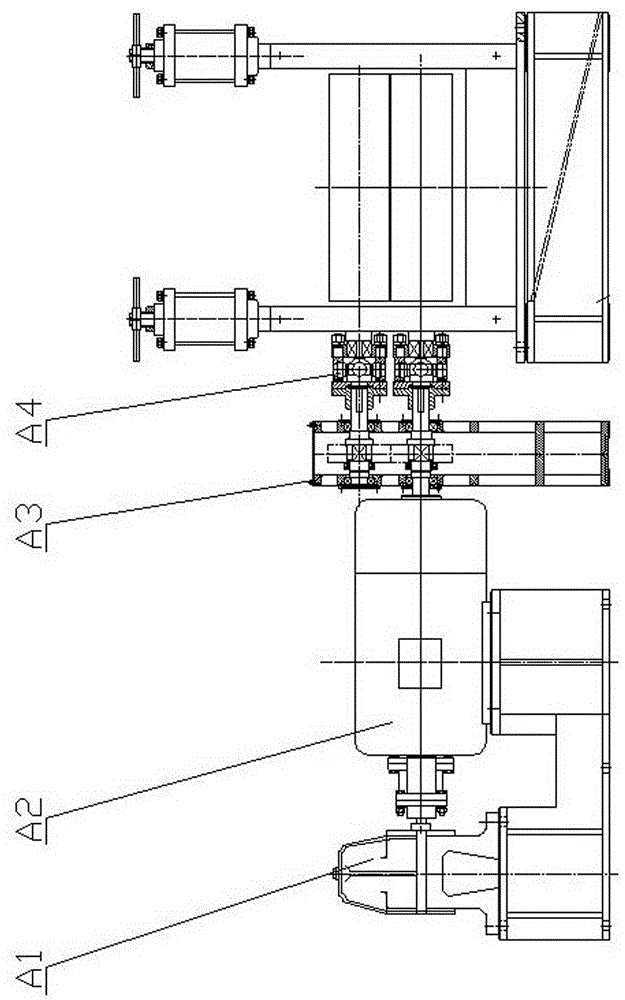

Slag gasifier for pressurized fixed bed

InactiveCN103436296AWide gasification rangeImprove carbon conversionCombustible gas productionSolid fuelFixed bed

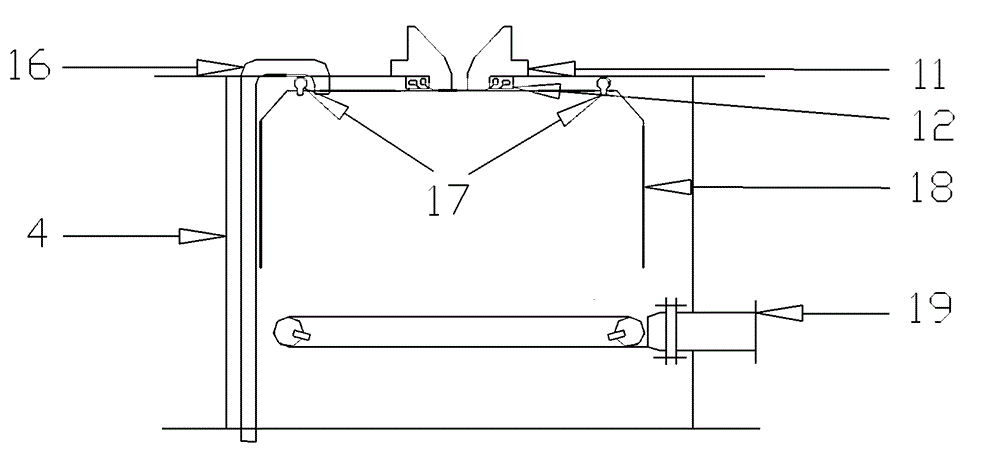

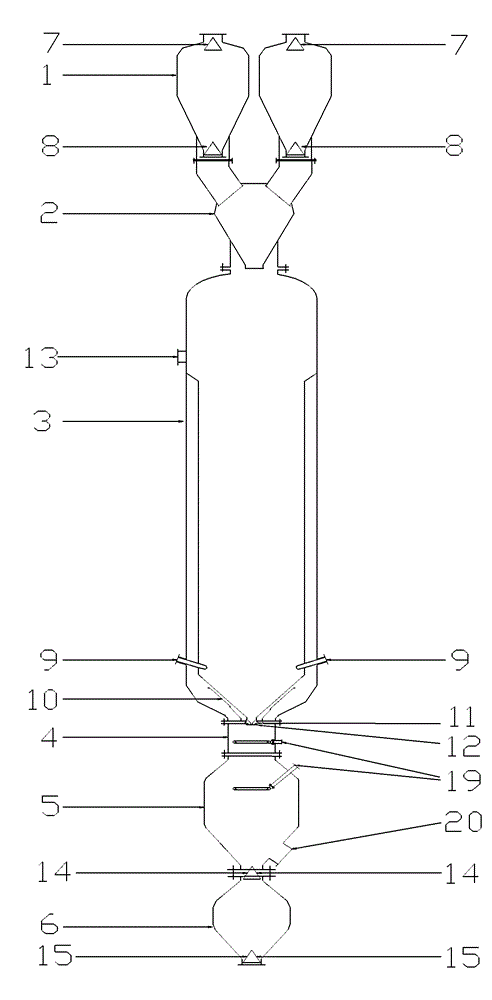

The invention relates to a slag gasifier for a pressurized fixed bed. The slag gasifier comprises a coal lock for intermittently taking coal from a bunker and feeding the coal into a pressurized gasifier container, a transition bin enabling the coal in the coal lock to be fed in the pressurized gasifier container conveniently, the pressurized gasifier container for combusting and gasifying carbon-containing solid fuels at a certain temperature and with certain pressure by virtue of a gasifying agent from a nozzle, a connection pup joint for gasifying operations of slagging, chilling, evacuation and the like, a chilling chamber for chilling and cooling molten slag and a slag lock for storing vitric slag particles and discharging the vitric slag particles to the outside by a cone valve. An operation method of the slag gasifier comprises the steps of adjusting the temperature of a raw gas outlet, gasifying carbon-containing solid fuels, adjusting the gasifying load of the gasifier, controlling the operation pressure of the gasifier, controlling the pressure difference between the connection pup joint and the gasifier, slag discharge of a slag discharging port and slag support operations, chilling and cooling molten slag, controlling water quantity of the chilling chamber to remove heat of the molten slag, storing slag particles and discharging the slag particles to the outside.

Owner:SHANGHAI ZEMAG MINDAC MACHINERY EQUIP

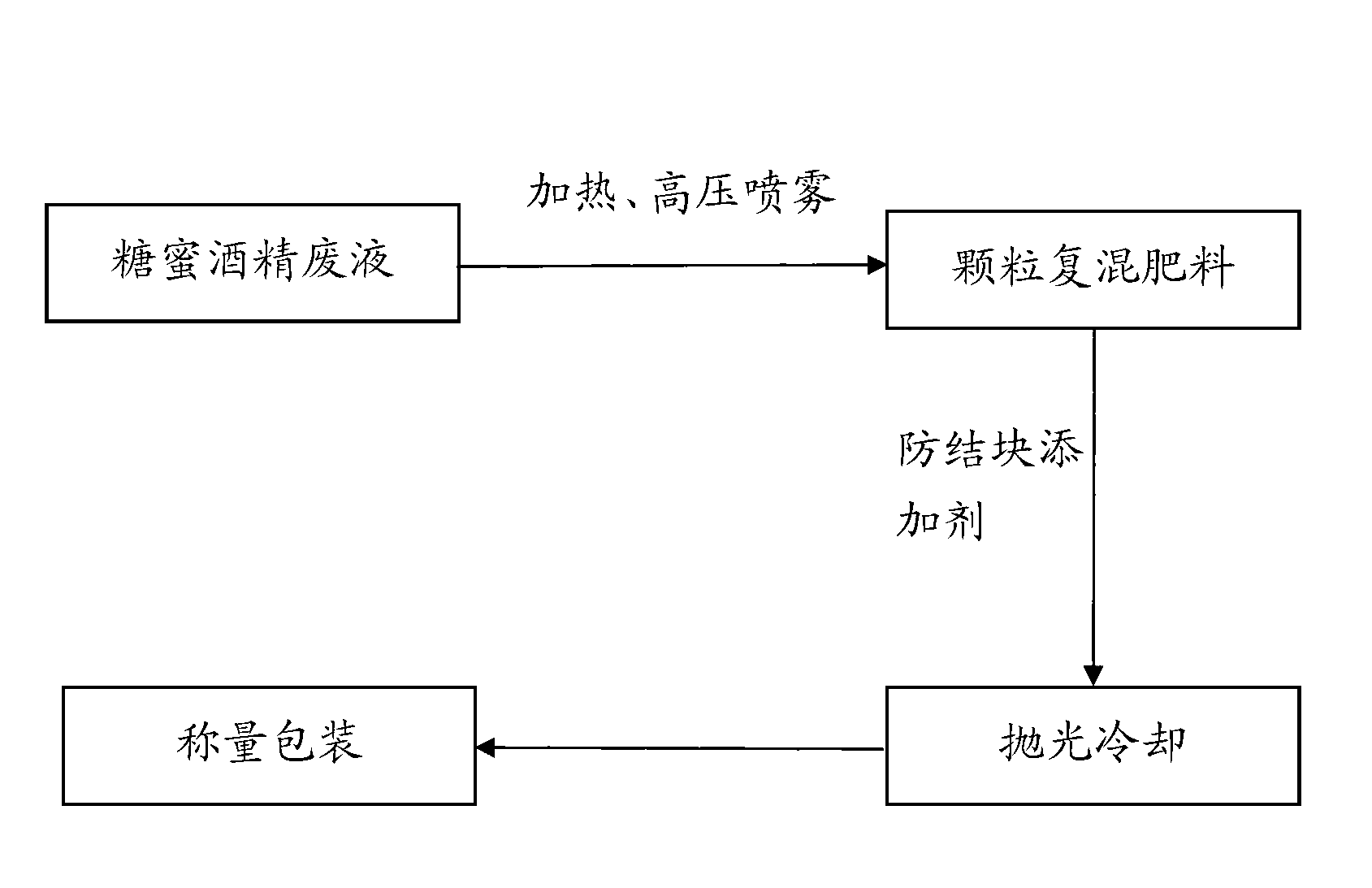

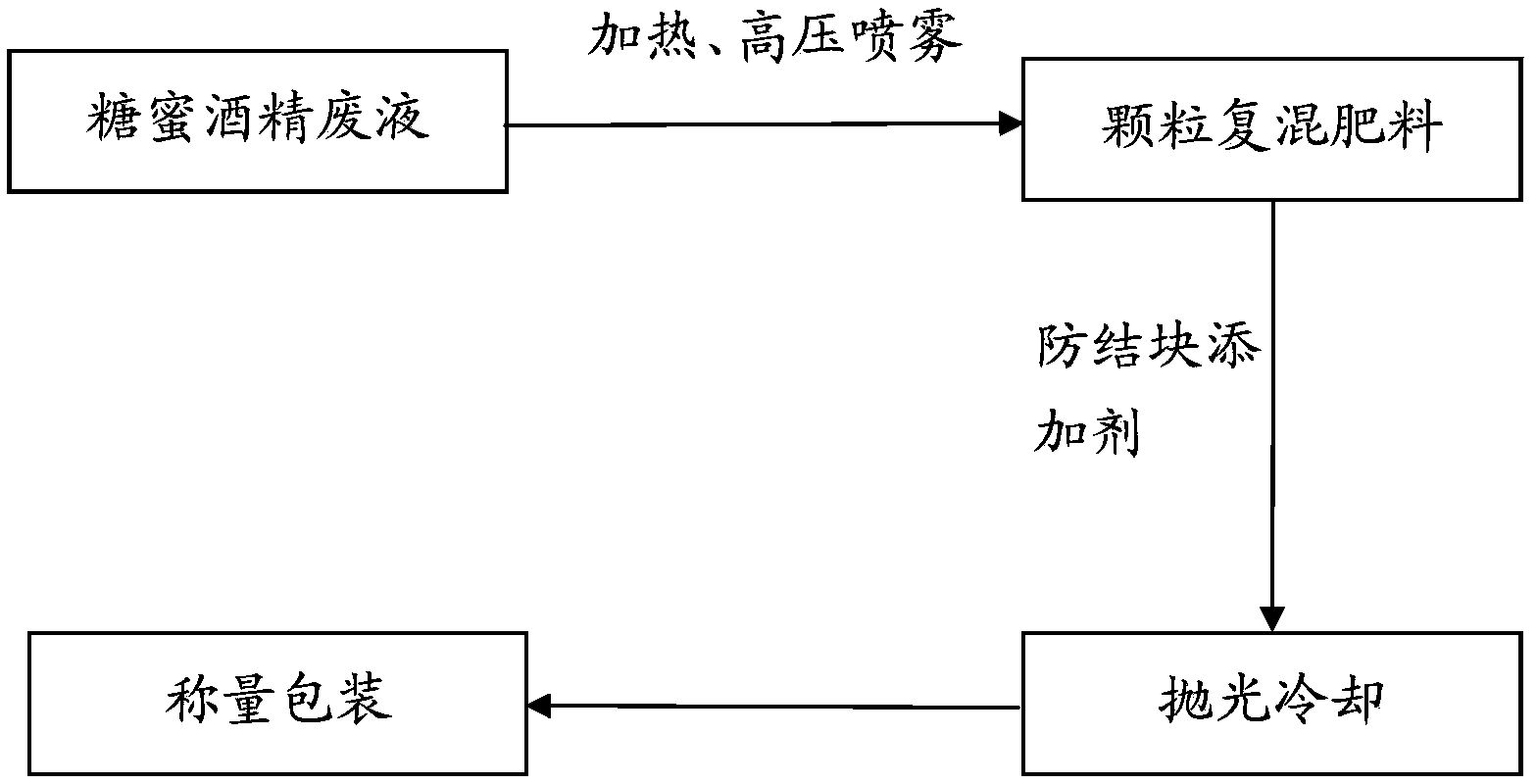

Anti-blocking compound fertilizer and preparation method thereof

ActiveCN102850140AGood anti-knot application effectRealize the big cycle of resourcesFertilizer mixturesAlcoholOrganic matter

The invention relates to an anti-blocking compound fertilizer and a preparation method of the compound fertilizer; the anti-blocking compound fertilizer is prepared by coating molasses alcohol waste liquid concentrate on the surface of the compound fertilizer; the organic substances in a molasses alcohol waste liquid are fully used for covering the surface of the granulated fertilizer, so that the fertilizer salt base is avoided being separated out, and the double effects of enveloping and preventing blocking can be achieved; meanwhile, the mineral elements in the molasses alcohol waste liquid is fully used for preparing the fertilizer and can be absorbed by crops, so that the double effects of environmental management and refuse reclamation can be achieved; and the method opens a new way for the comprehensive treatment of the molasses alcohol waste liquid.

Owner:广西洁能生物科技有限公司

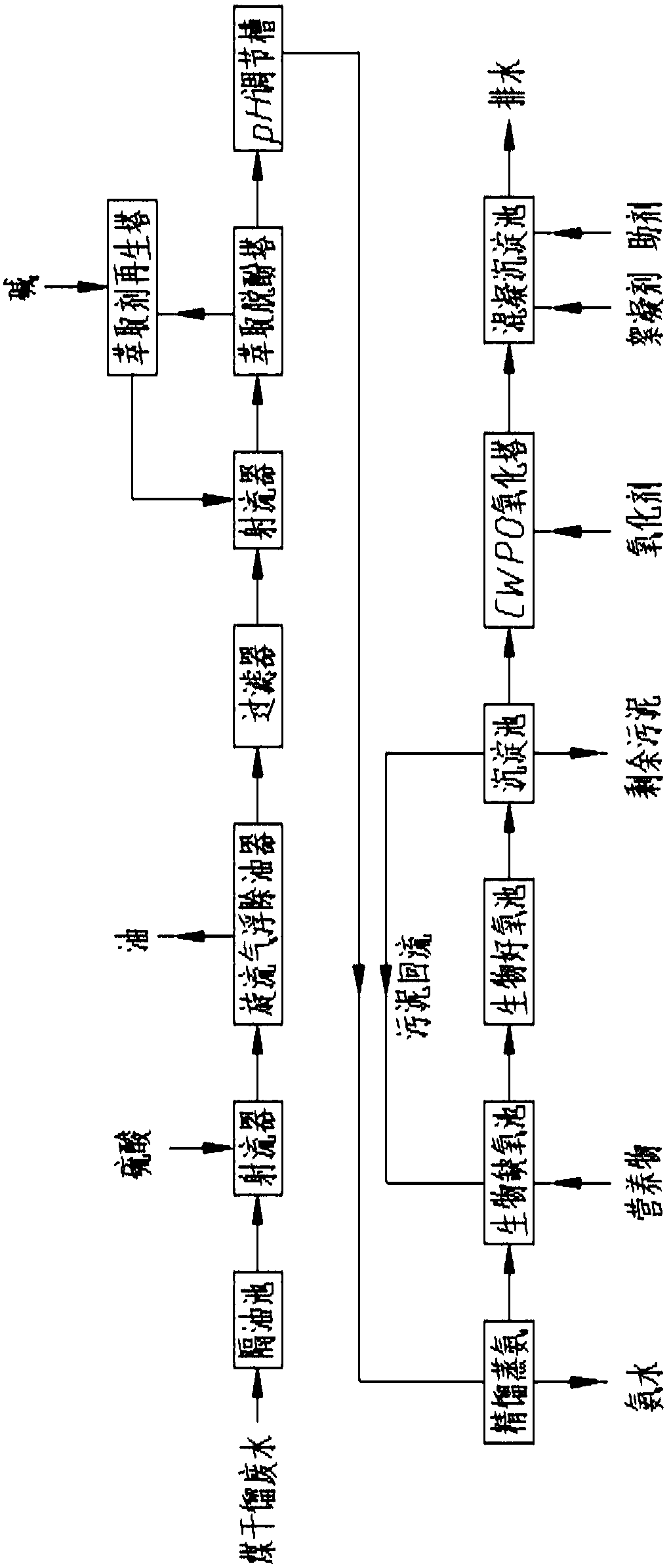

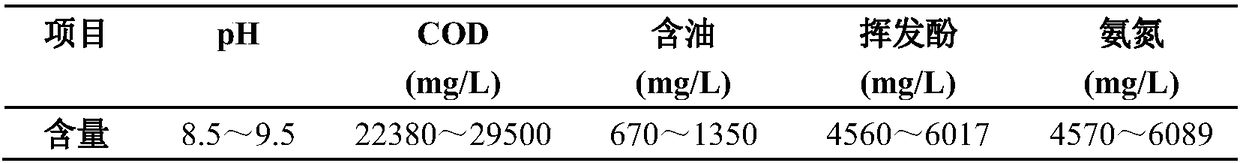

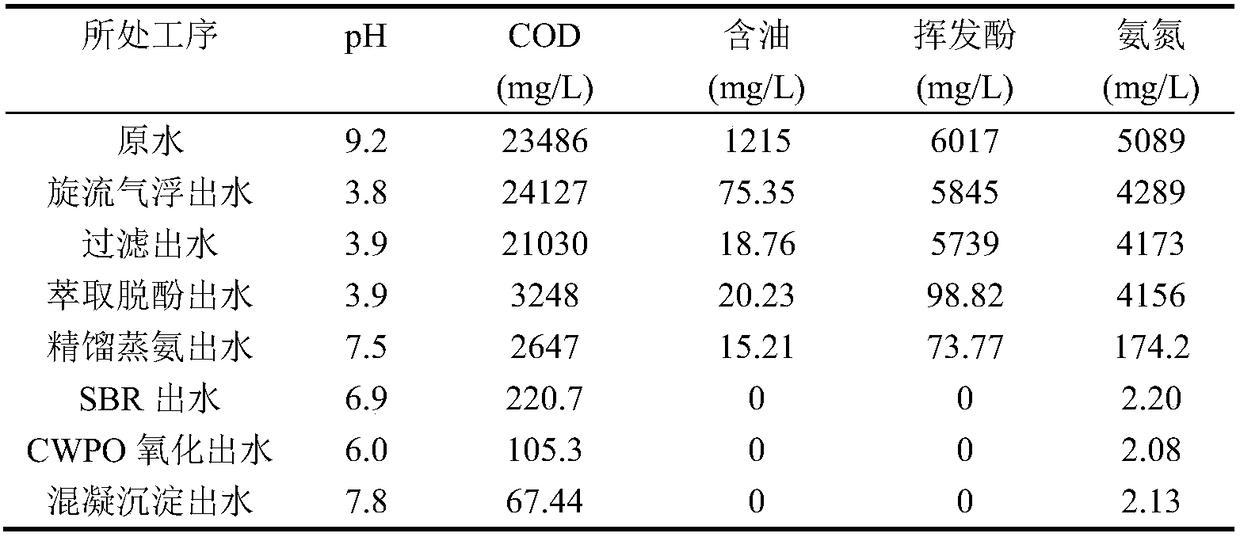

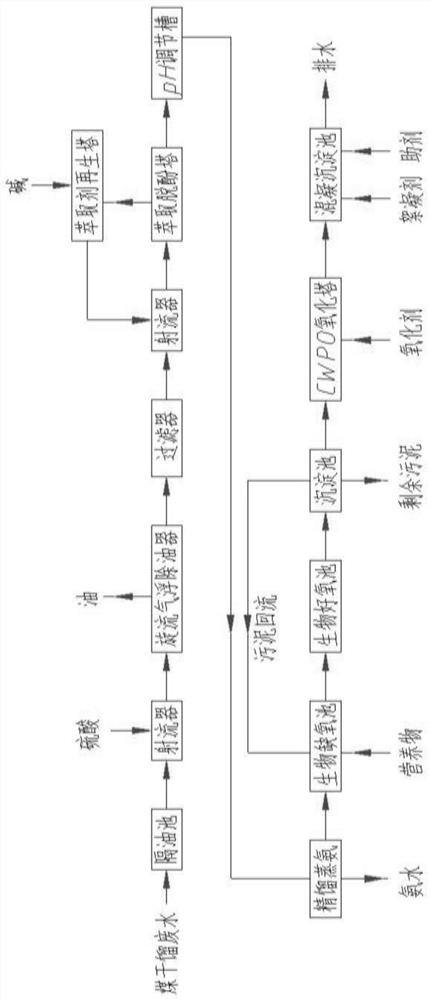

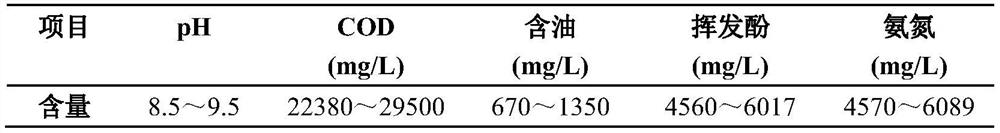

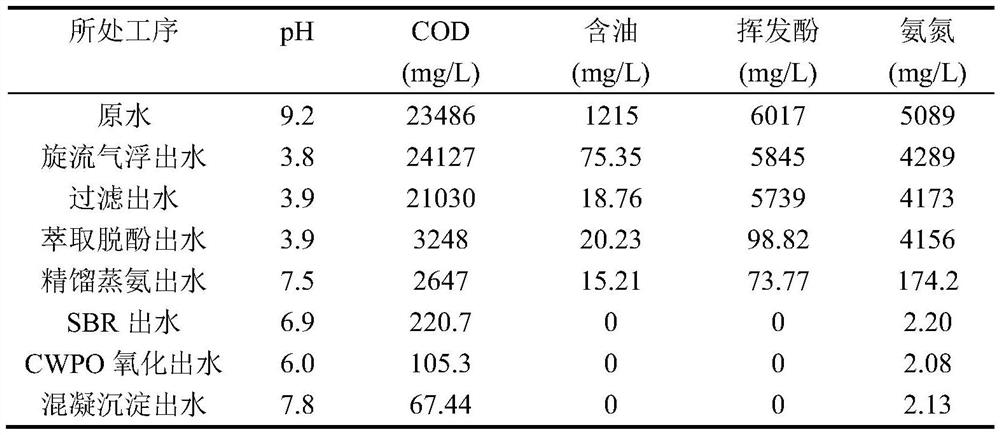

Method for treatment of wastewater from dry distillation of coal

ActiveCN108147612AHigh efficiency of extraction and removal of phenolsReduce extraction timeFatty/oily/floating substances removal devicesWater contaminantsChemical industryOxygen deprivation

The invention provides a method for treatment of wastewater from dry distillation of coal. By adopting a technology of combining units of oil isolation, cyclone air flotation, filtration, extraction dephenolization, rectification and ammonia distillation, biological oxygen deprivation, SBR oxidation, CWPO oxidation, coagulation sedimentation and the like, the method can effectively remove organicpollutants like coal tar, ammonia nitrogen and phenols in the wastewater from dry distillation of the coal, wherein the oil removal rate of a cyclone air flotation unit reaches 93.8%; the volatile phenol removal rate of an extraction dephenolization unit reaches 98.3%; and the ammonia nitrogen removal rate of a rectification and ammonia distillation unit reaches 95.8%. The method provided by the invention has mature technology, is stable and reliable, can treat the wastewater from dry distillation of the coal to reach the direct discharge requirements of the Emission Standard of Pollutants forCoking Chemical Industry GB16171-2012, and has popularization values.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

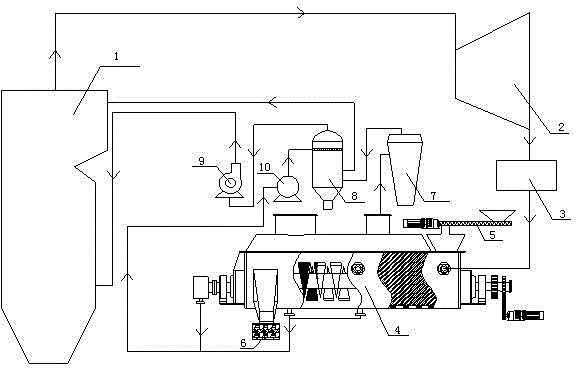

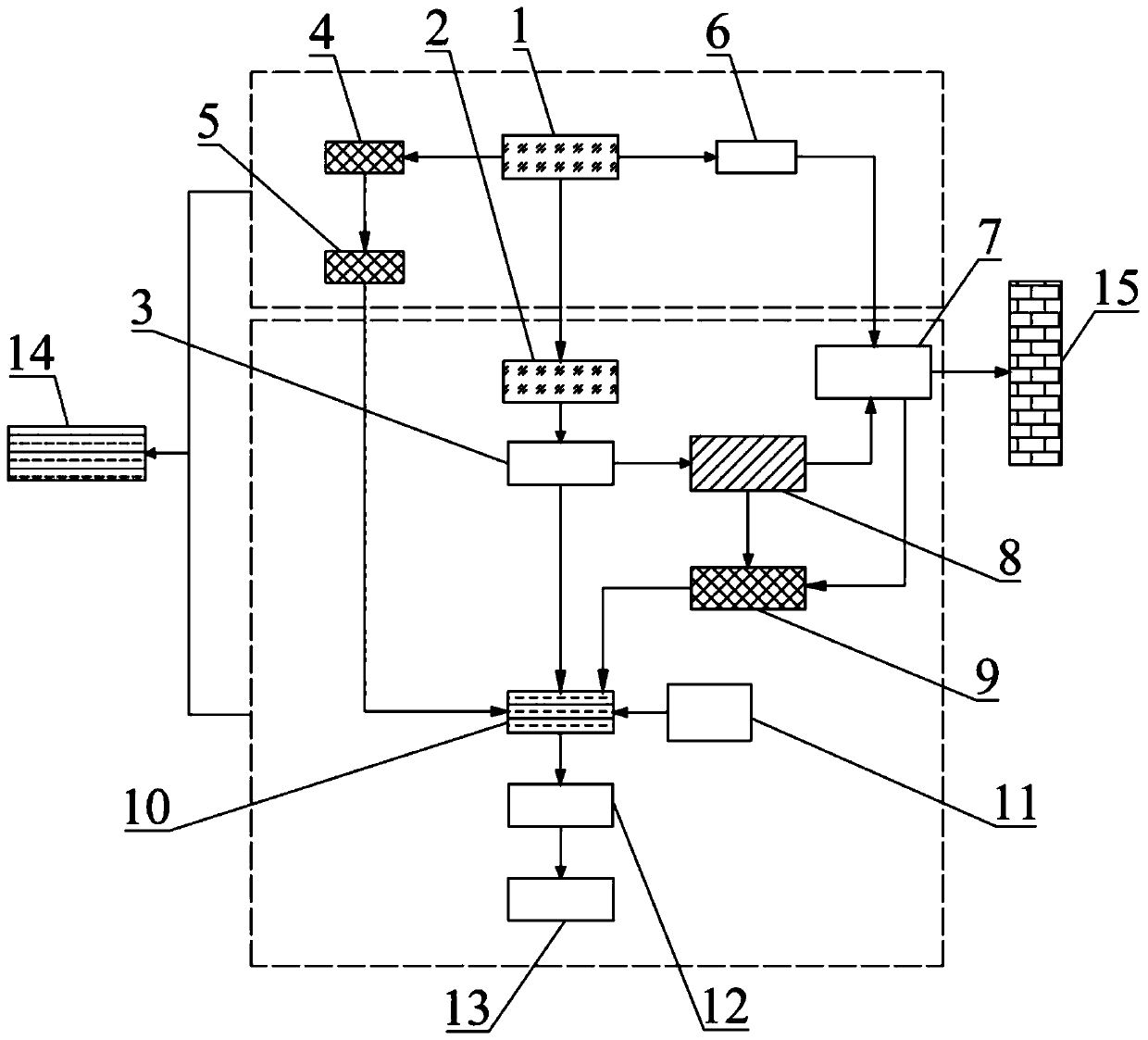

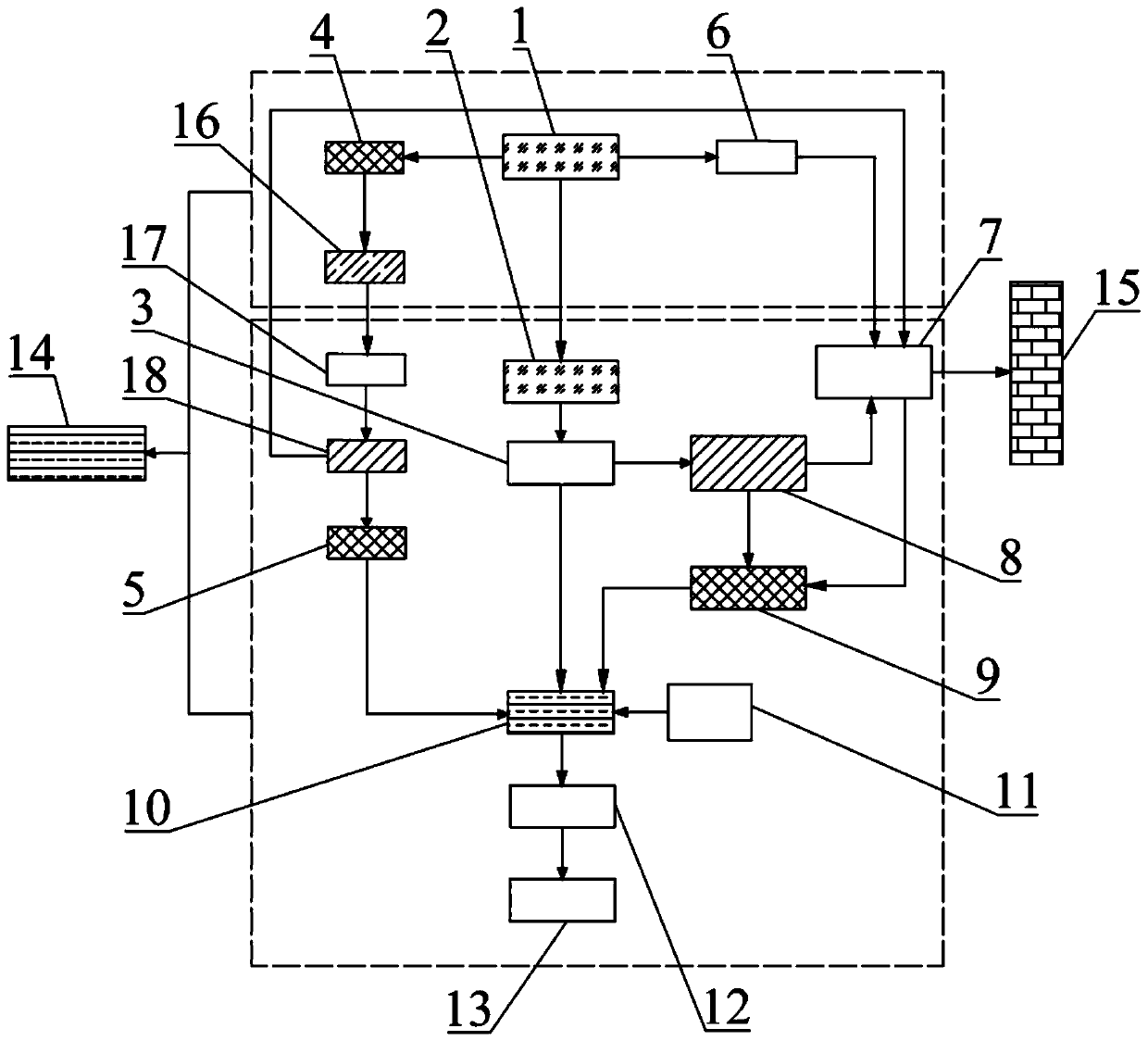

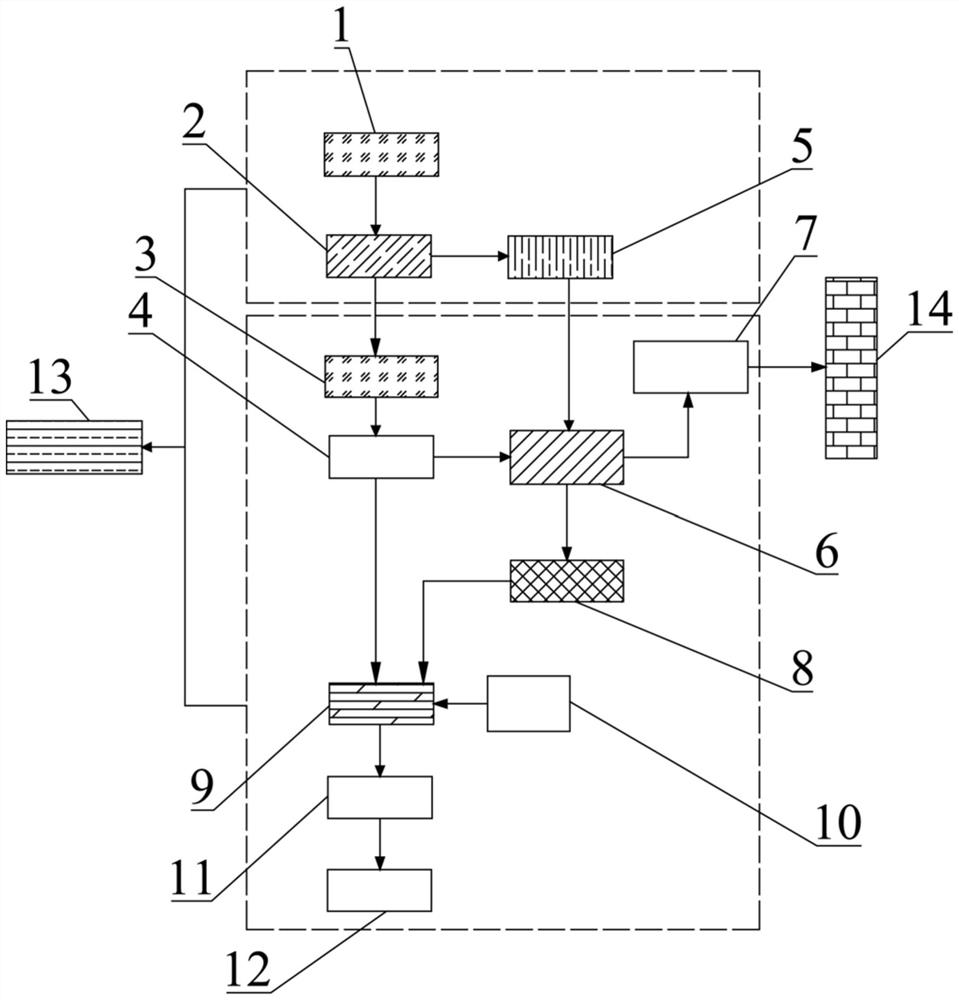

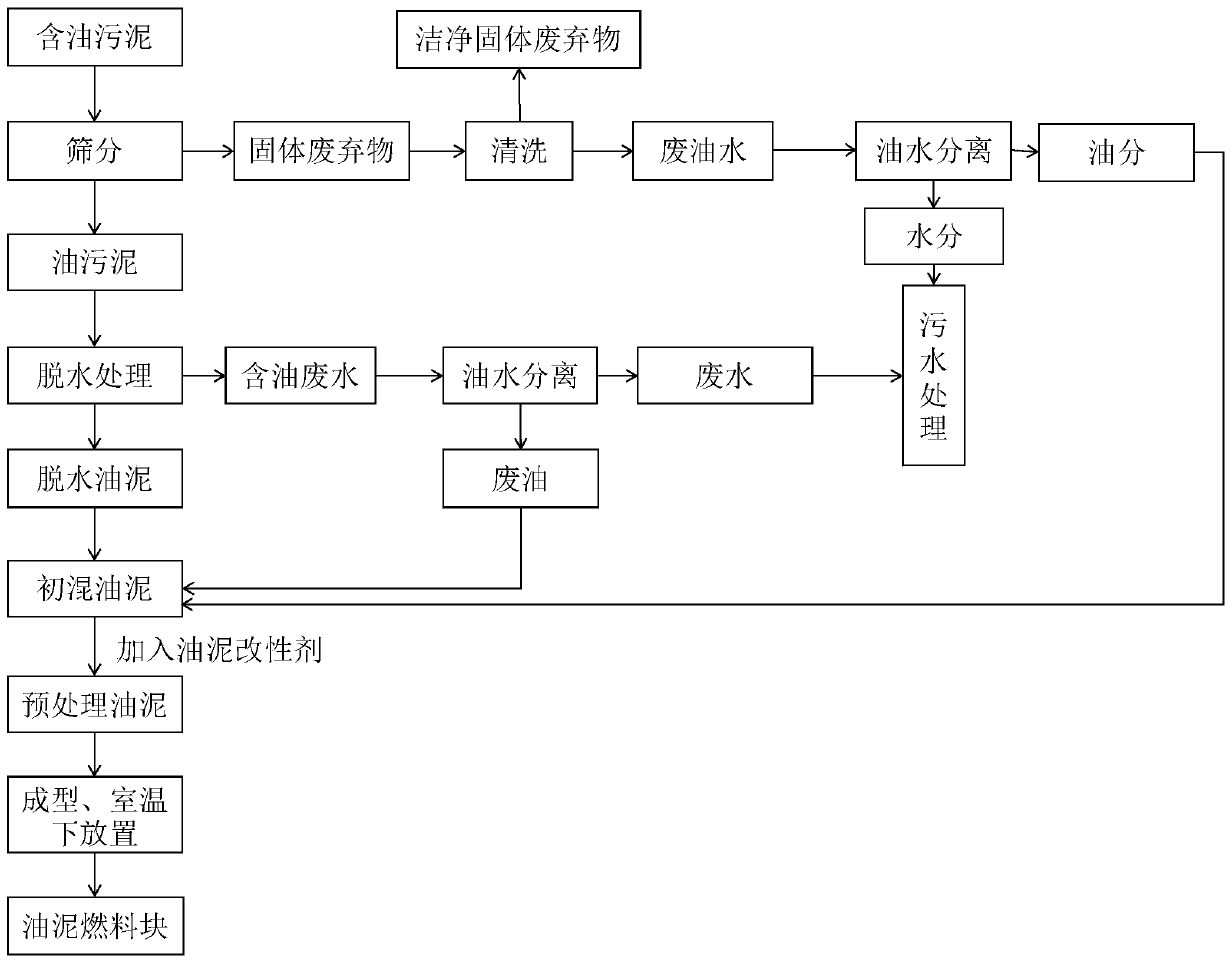

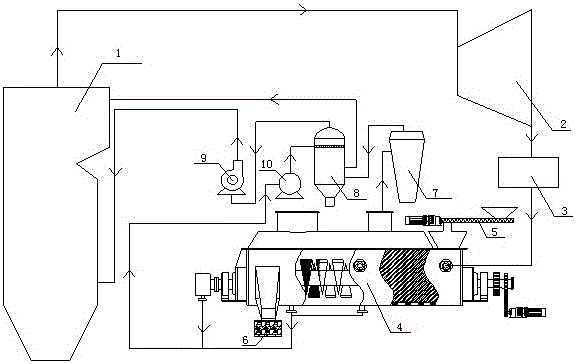

Sludge drying incineration system based on thermal power plant

ActiveCN104628237ALow costImprove operabilityCombination devicesSludge treatment by de-watering/drying/thickeningPollutantThermal power station

The invention discloses a sludge drying incineration system based on a thermal power plant. The system comprises a sludge drying system and a sludge mixing incineration system, wherein the sludge drying system comprises a heat supply system, a feeding system, a paddle type sludge dryer, a dead steam treating system, a dead steam recycling system and a dried sludge collecting and handling system; and the sludge mixing incineration system comprises a dried sludge mixing system and a dried sludge incineration system. According to the sludge drying incineration system based on the thermal power plant, sludge is dried through high-temperature steam produced by a boiler of the thermal power plant; the dried sludge is incinerated and the resulting heat is used for producing steam; the whole process is free of pollutant; therefore, an effective way is actually developed for recycling the wastes and treating wastes with the wastes, the social and environmental benefits are obvious, and a feasible way is provided for harmless handling, reducing handling and recycling of sludge.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

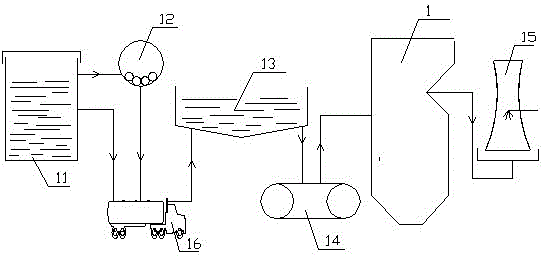

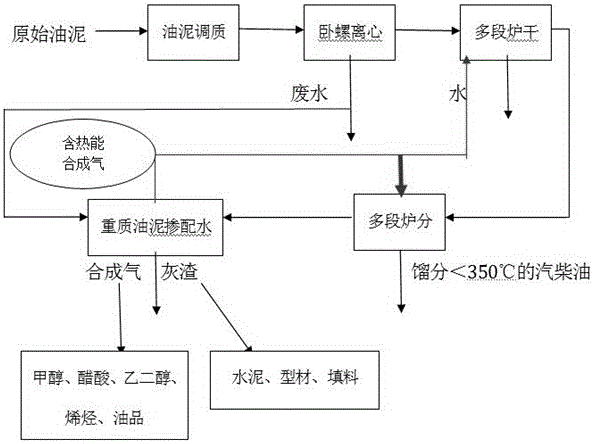

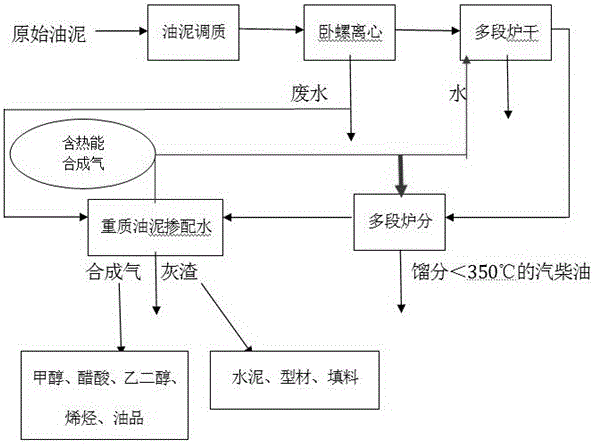

Oil-sludge separation and gasification recycling method

ActiveCN105693055AAchieve fractional distillation extractionSimple processSludge treatmentSpecific water treatment objectivesCoal waterHigh energy

The invention discloses an oil-sludge separation and gasification recycling method. Harmless treatment and recycling of oily sludge are realized by technical coupling of oil-sludge reduction, drying and separating integrated treatment and high-temperature coal water slurry gasification. Defects of high power consumption, high secondary pollution, poor quality of separated oil and the like in a traditional oily sludge extraction process can be avoided. A multi-stage furnace is adopted for drying and dewatering of high-oil-content sludge and multi-stage fractional distillation extraction of gasoline and diesel, residual heavy oil and silt avoid complex and high-energy-consumption separation and can be directly subjected to high-temperature harmless gasification treatment, generated heat is utilized with synthesis gas serving as a carrier, and consequently energy utilization and recovery of effective oil components in oily sludge are realized. By separation and gasification coupled treatment through the multi-stage furnace, the high-energy-consumption oily sludge thermal treatment process realizes self-sufficiency of energy while generation of resources such as gasoline, diesel, synthesis gas and the like is realized, so that recycling and harmless treatment of the oily sludge are truly realized, and sustainable economic development is realized as well.

Owner:SHAANXI YANCHANG PETROLEUM GRP

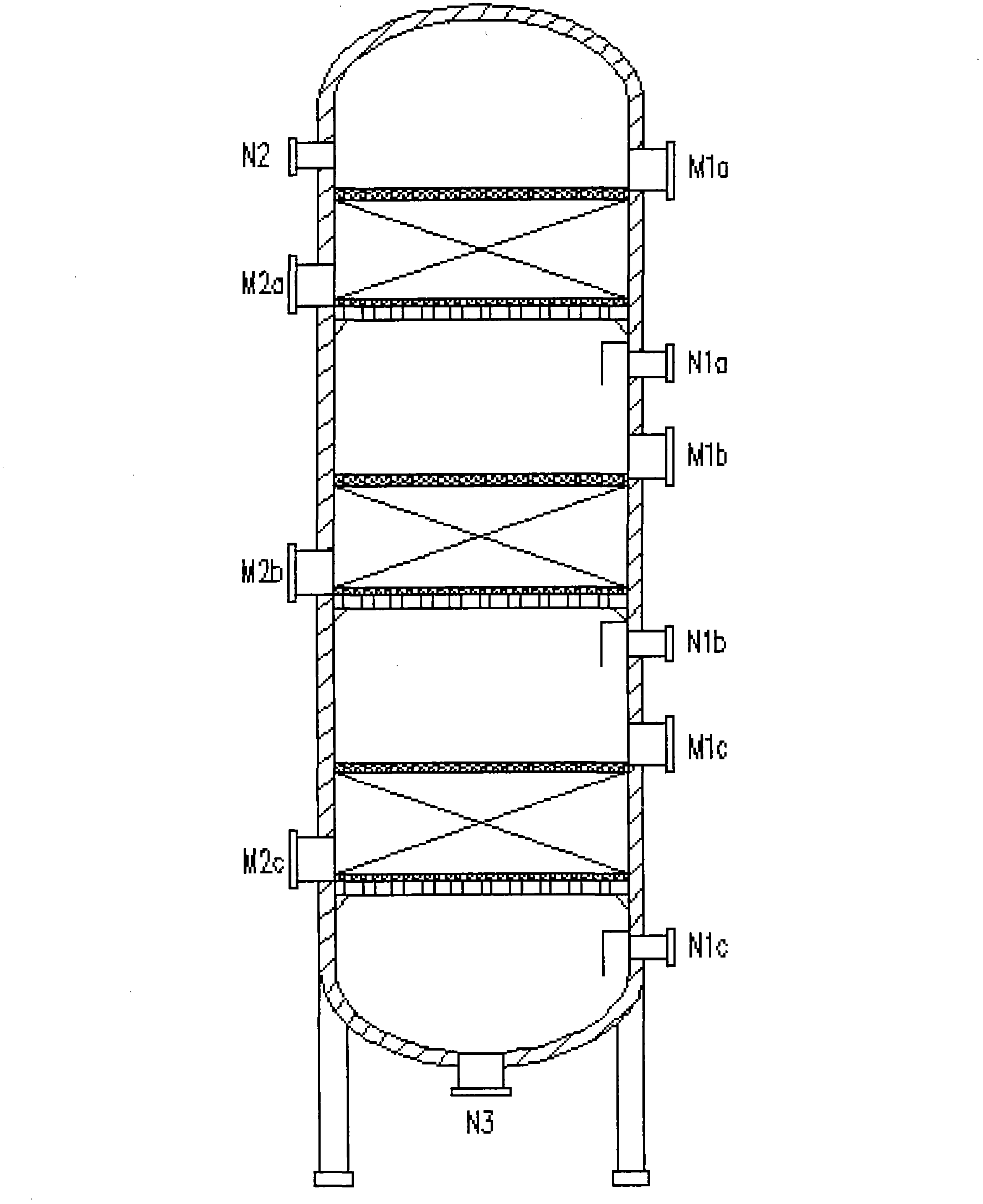

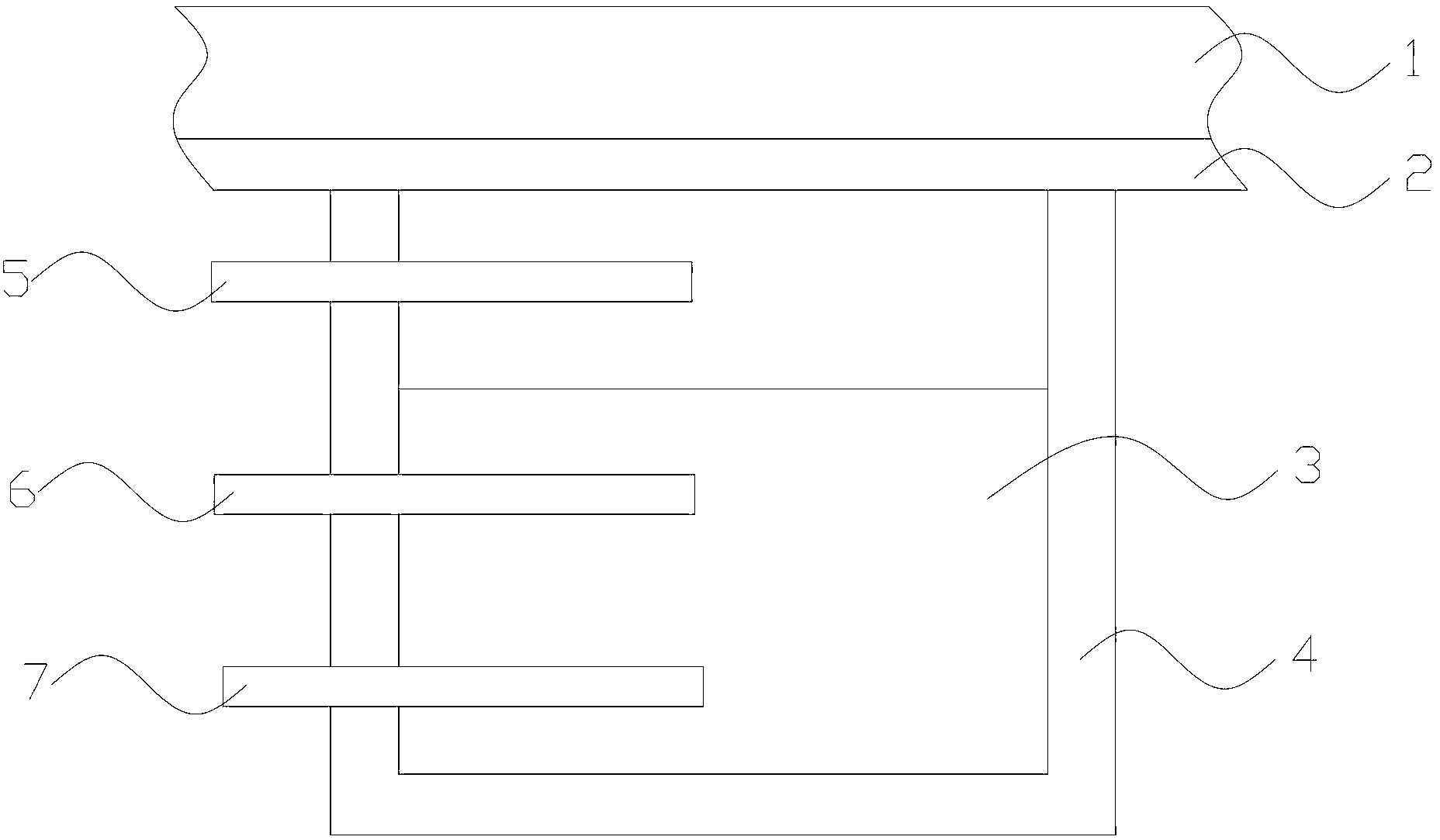

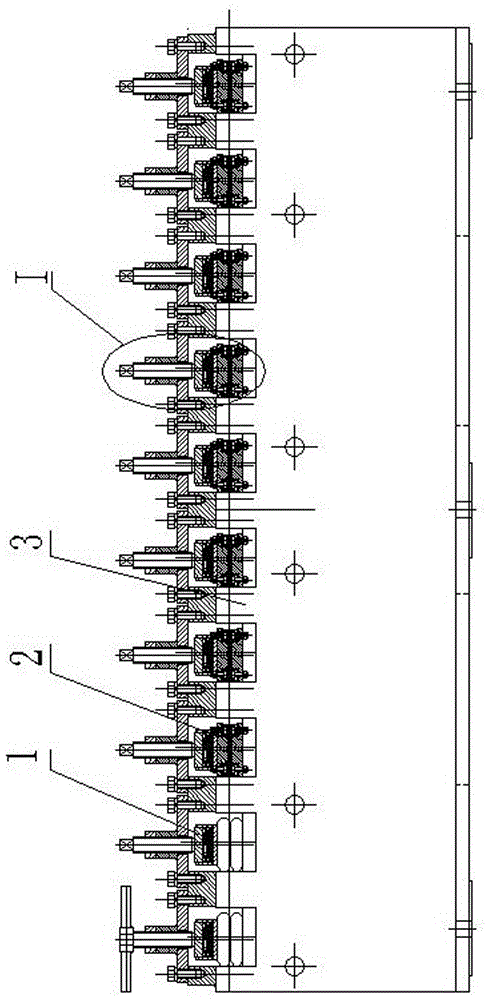

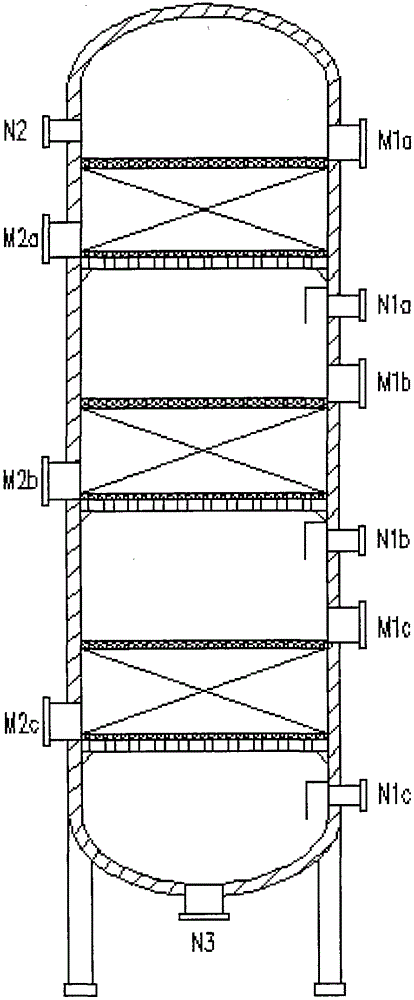

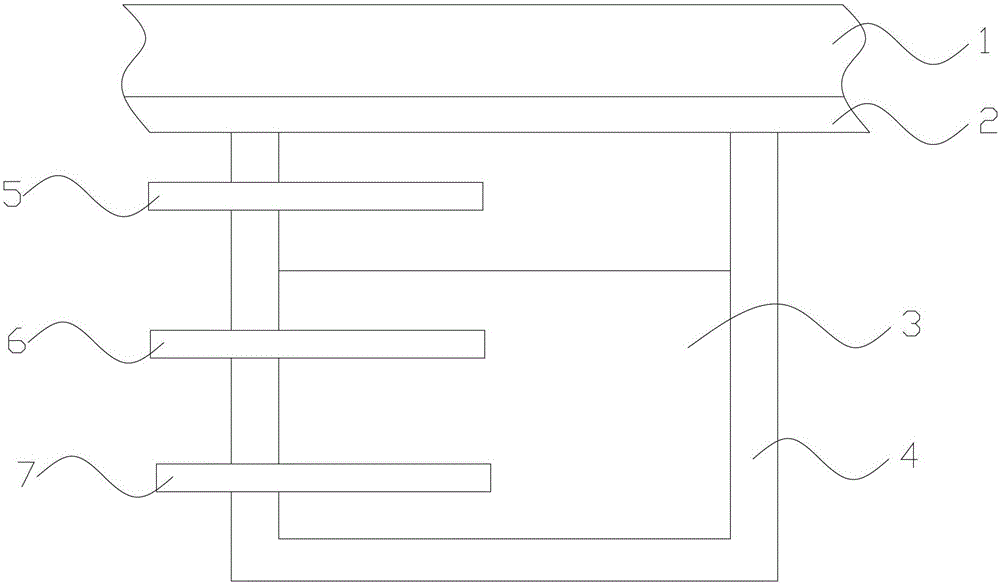

Multi-stage catalyzed sorption reactor

ActiveCN103007747AReduce exhaust gas treatment investmentDoes not pollute the environmentDispersed particle separationExhaust gasActivated carbon

The invention discloses a multi-stage catalyzed sorption reactor which comprises a reactor body, catalyzed sorption beds, charging holes, discharge holes, gas inlets and a gas outlet, wherein the catalyzed sorption beds are fixed in the reactor body to divide the interior of the reactor body into independent catalyzed sorption spaces; the discharge holes are formed in the reactor body on the upper surfaces of the catalyzed sorption beds; the charging holes are formed in the reactor body in the middles of the independent catalyzed sorption spaces formed by the upper surfaces of the catalyzed sorption beds; the gas inlets are formed in the reactor body on the lower surfaces of the catalyzed sorption beds; and the gas outlet is formed at the upper part of the reactor body. The charging holes and the discharge holes are used for filling high-efficiency converted-sorption activated carbon desulfurizing agents; acid gas enters the reactor body through the gas inlets, and conducts sorption and catalysis with the high-efficiency converted-sorption activated carbon desulfurizing agents through the catalyzed sorption beds; the high-efficiency converted-sorption activated carbon desulfurizing agents convert sulfur-bearing matters in the acid gas to simple sulfur, simple sulfur is sorbed in micropores of a catalyst; and desulfurized tail gas is discharged out of the reactor body through the gas outlet of the reactor body.

Owner:JIANGSU HENGXIN ENERGY TECH

Double drying process sludge treatment apparatus

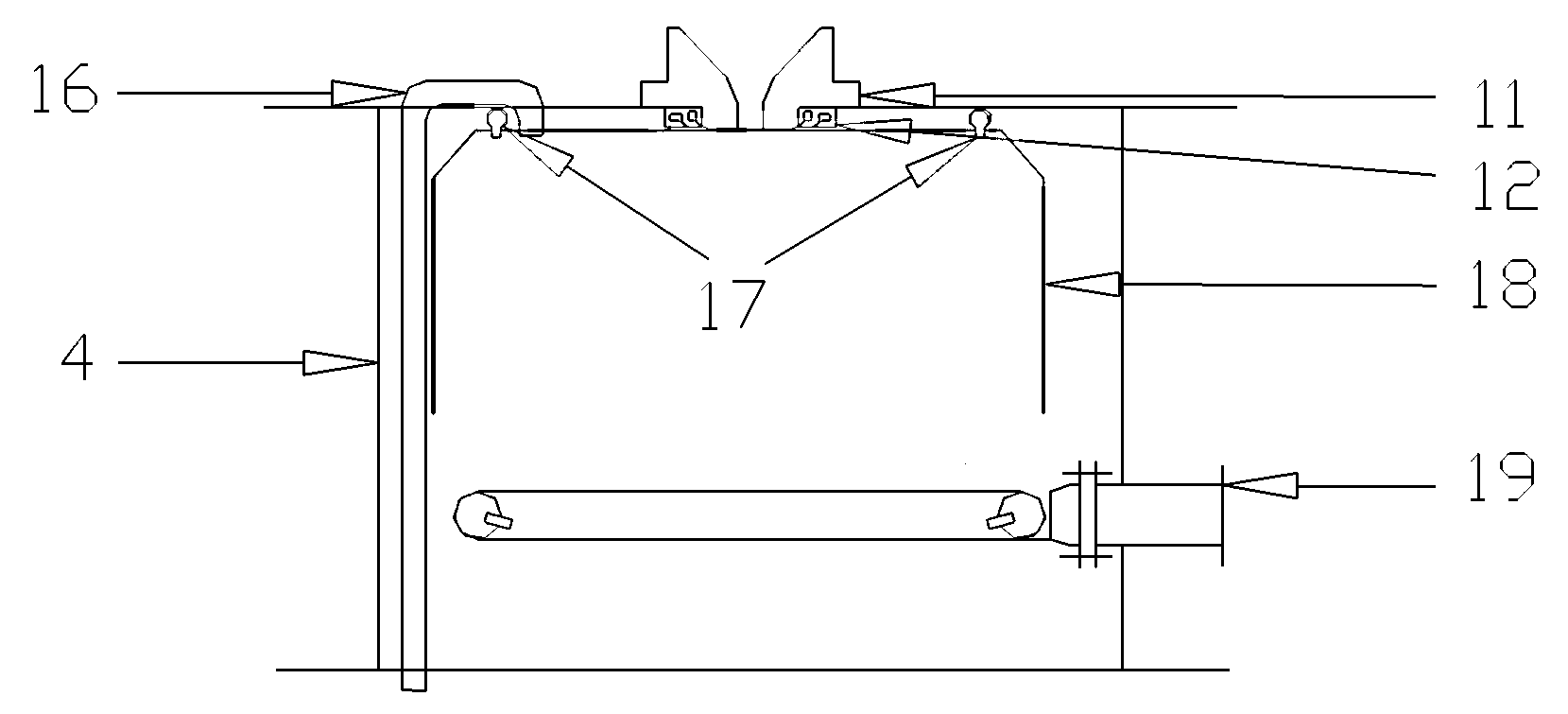

InactiveCN107777853AEliminate transportEliminate a series of problems such as storageSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisSludgeFiltration

The invention belongs to the technical field of sludge treatment, and relates to a double-dry sludge treatment device. A plate and frame filter press drier is provided with several independent filter press drying units. The filter press drying unit includes a heating plate, and the two sides of the heating plate A tympanic plate is provided, filter cloths are provided on both sides of the tympanic plate, and several protrusions are provided on the side of the tympanic plate close to the filter cloth to support the filter cloth. The cavity between the heating plate and the heating plate is a drying chamber; the stirring tank is connected with the sludge chamber of the filter press drying unit one by one through branch pipes, and feeds in parallel. There is a screw conveyor under the filter press drying unit, the screw conveyor is connected to the inlet of the retort furnace, and the retort furnace is respectively connected to the gas storage tank and the biochar storage bin; the gap between the tympanum plate and the filter cloth is connected to the steam collection pipe , the steam collection pipe is connected to the steam compressor, the output of the steam compressor is connected to the inlet of the heating plate, and the bottom of the heating plate is provided with a condensed water outlet; the secondary steam compression is used to reduce the boiling point, and the resource utilization rate is high, occupying an area The area is small.

Owner:王政峰

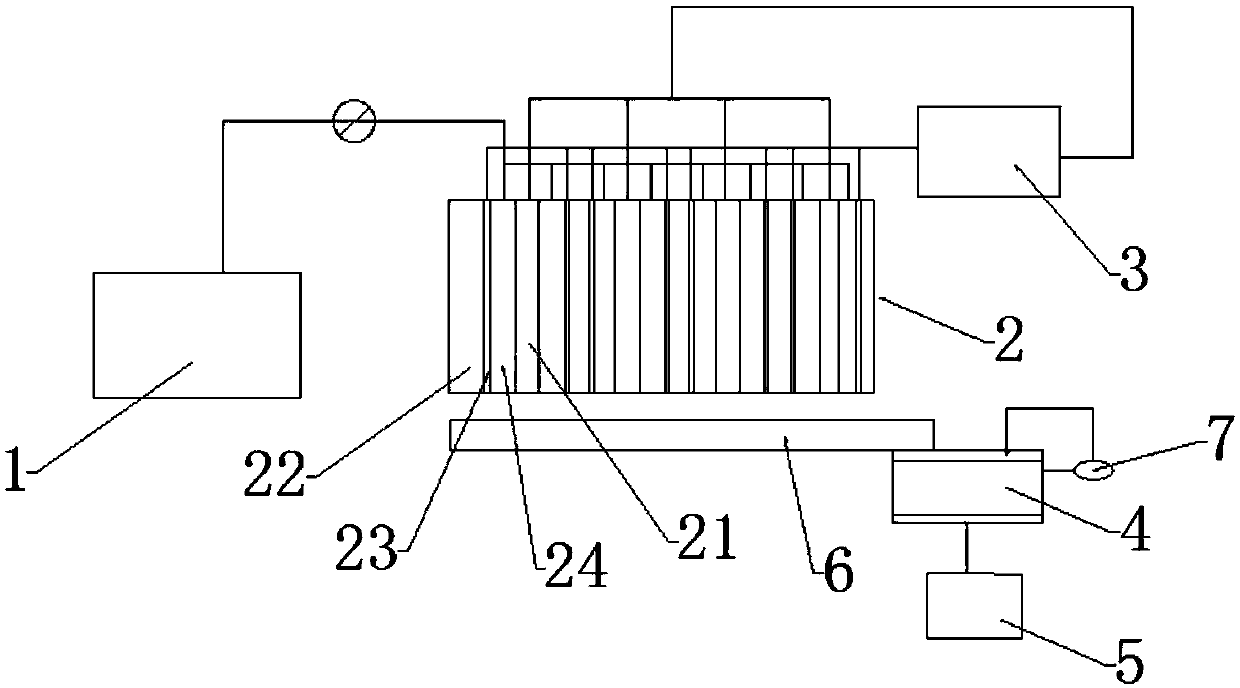

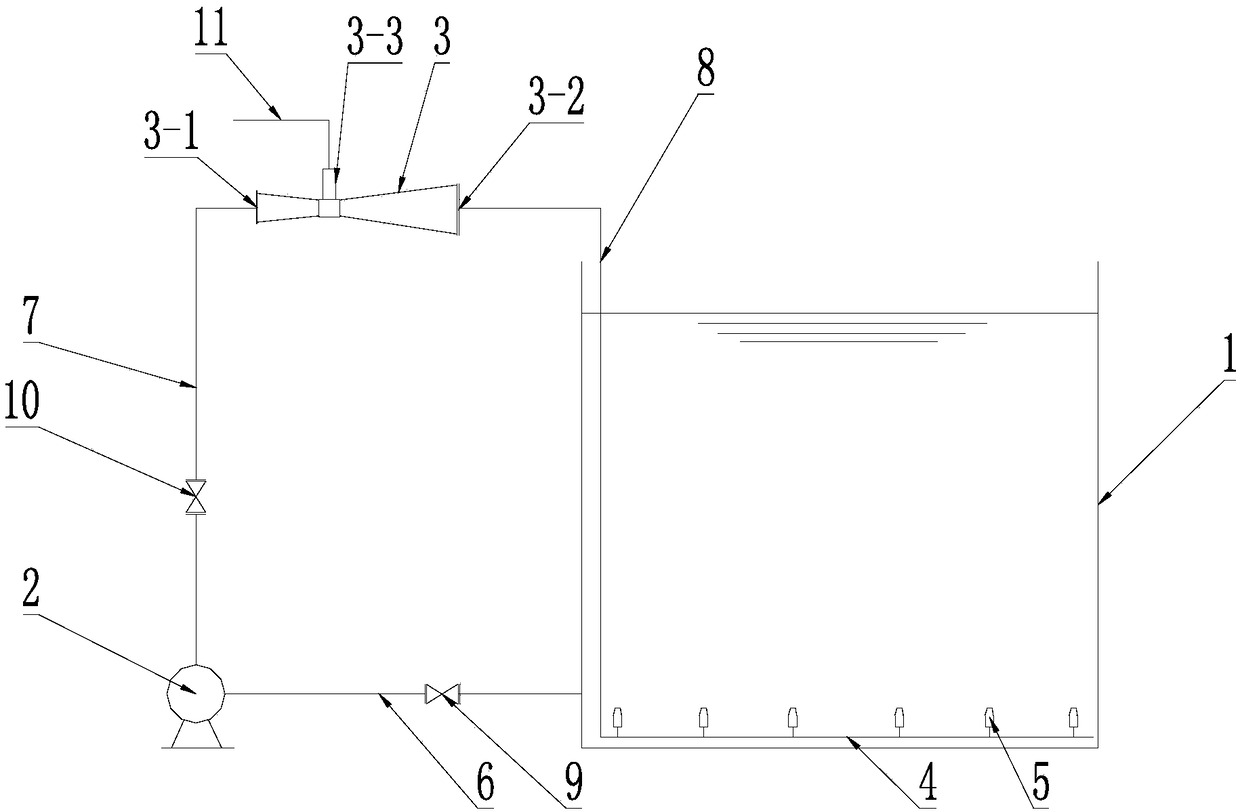

Energy-saving type waste water and waste gas combined treatment device

PendingCN108217980AHigh strengthReduce settingsDispersed particle separationBiological treatment apparatusWater solubleCombined treatment

The invention discloses an energy-saving type waste water and waste gas combined treatment device. The energy-saving type waste water and waste gas combined treatment device comprises a waste water treatment pool (1), a water pump (2), an ejector (3) and a jet flow device; the jet flow device is arranged in the waste water treatment pool (1); the waste water treatment pool (1) is connected to a water inlet of the water pump (2) through a first pipeline (6); a water outlet of the water pump (2) is connected to an ejector inlet (3-1) of the ejector (3) through a second pipeline (7); an ejector outlet (3-2) of the ejector (3) is connected to the jet flow device through a third pipeline (8); and a fluid inlet of the ejector (3) is connected to a waste gas pipeline (11) with water-soluble and high-temperature waste gas inside. The energy-saving type waste water and waste gas combined treatment device provided by the invention can treat waste gas and waste water simultaneously, reduce wastegas treatment cost and improve waste water treatment efficiency.

Owner:SUZHOU KETE ENVIRONMENTAL PROTECTION CO LTD

Nuclear power plant radioactive organic waste splitting and mineralizing treatment reactor

PendingCN109273129AImprove securityMeet the requirements of various indicators for long-term disposalPyrolysis reactionsChemical/physical/physico-chemical stationary reactorsOrganic solventWater vapor

The invention provides a nuclear power plant radioactive organic waste splitting and mineralizing treatment reactor, which comprises a reaction section and an expansion section, wherein a high-temperature water vapor inlet, a nitrogen inlet and an oxygen inlet are formed in the lower part of the reaction section; a resin slurry inlet, a catalyst inlet, a waste oil or waste organic solvent inlet, an anticoagulant inlet, a mineralizing agent inlet and an active carbon inlet are formed in the middle part of the reaction section; the expansion section is located above the reaction section; and thetop of the expansion section is provided with an organic dry waste or waste filter core inlet and a solid and gas outlet. Furthermore, the invention further provides a method for treating nuclear power plant radioactive organic wastes by adopting the nuclear power plant radioactive organic waste splitting and mineralizing treatment reactor.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +3

Slag gasifier for pressurized fixed bed

InactiveCN103436296BImprove carbon conversionImprove conversion rateCombustible gas productionSolid fuelEngineering

The invention relates to a slag gasifier for a pressurized fixed bed. The slag gasifier comprises a coal lock for intermittently taking coal from a bunker and feeding the coal into a pressurized gasifier container, a transition bin enabling the coal in the coal lock to be fed in the pressurized gasifier container conveniently, the pressurized gasifier container for combusting and gasifying carbon-containing solid fuels at a certain temperature and with certain pressure by virtue of a gasifying agent from a nozzle, a connection pup joint for gasifying operations of slagging, chilling, evacuation and the like, a chilling chamber for chilling and cooling molten slag and a slag lock for storing vitric slag particles and discharging the vitric slag particles to the outside by a cone valve. An operation method of the slag gasifier comprises the steps of adjusting the temperature of a raw gas outlet, gasifying carbon-containing solid fuels, adjusting the gasifying load of the gasifier, controlling the operation pressure of the gasifier, controlling the pressure difference between the connection pup joint and the gasifier, slag discharge of a slag discharging port and slag support operations, chilling and cooling molten slag, controlling water quantity of the chilling chamber to remove heat of the molten slag, storing slag particles and discharging the slag particles to the outside.

Owner:SHANGHAI ZEMAG MINDAC MACHINERY EQUIP

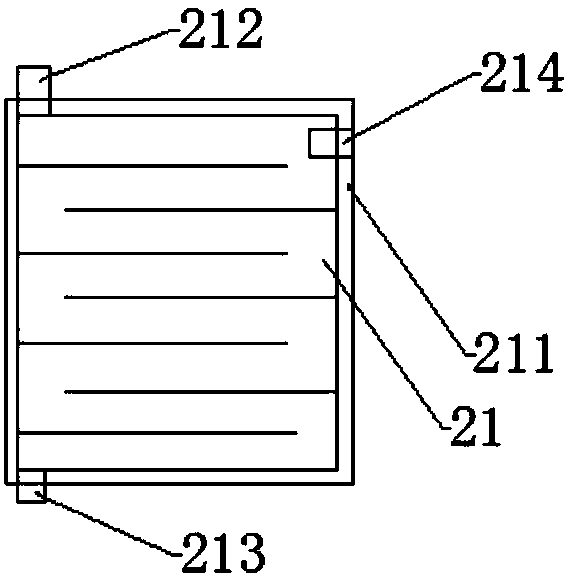

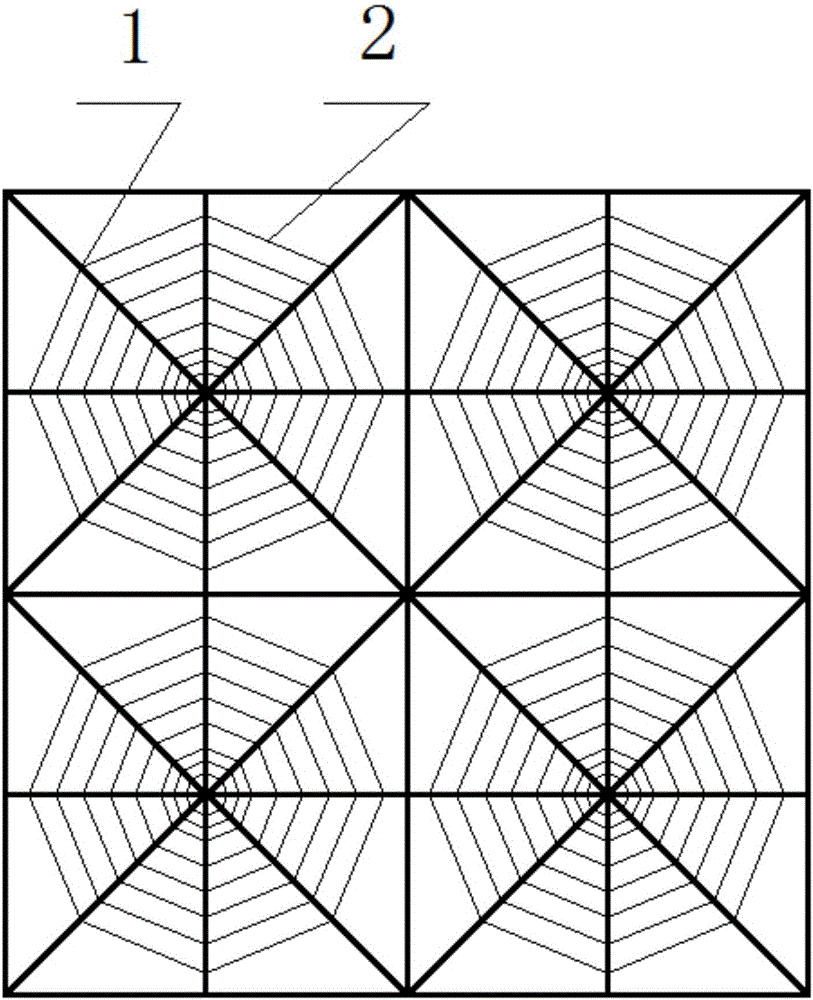

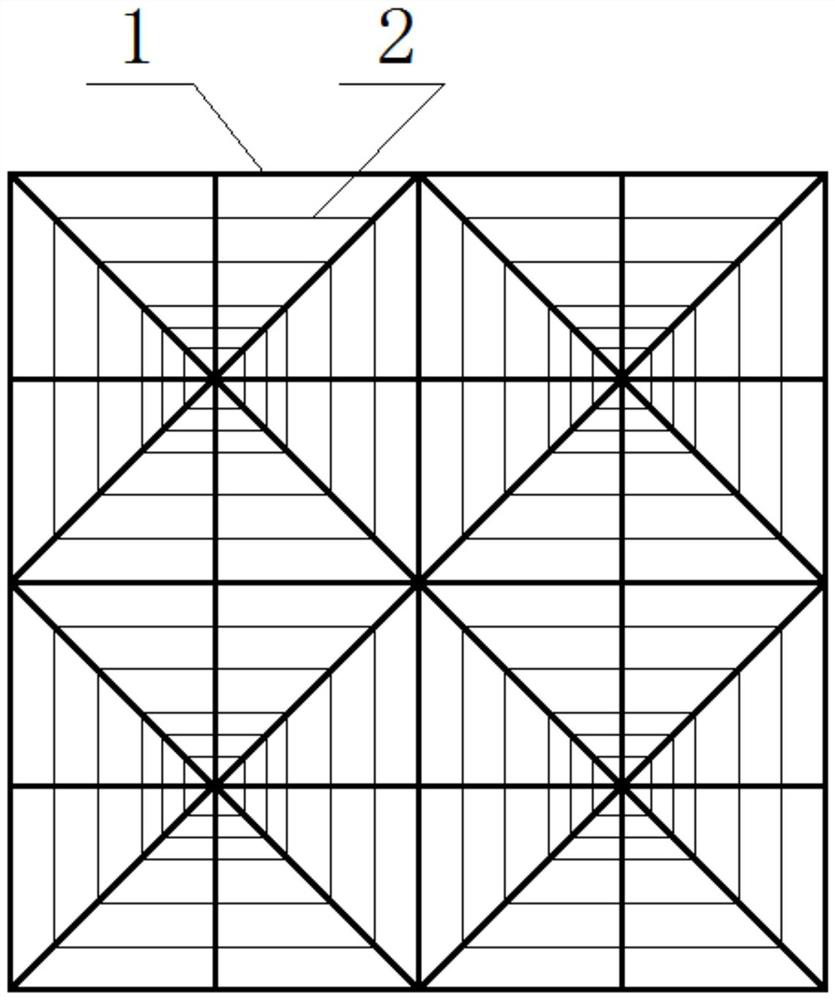

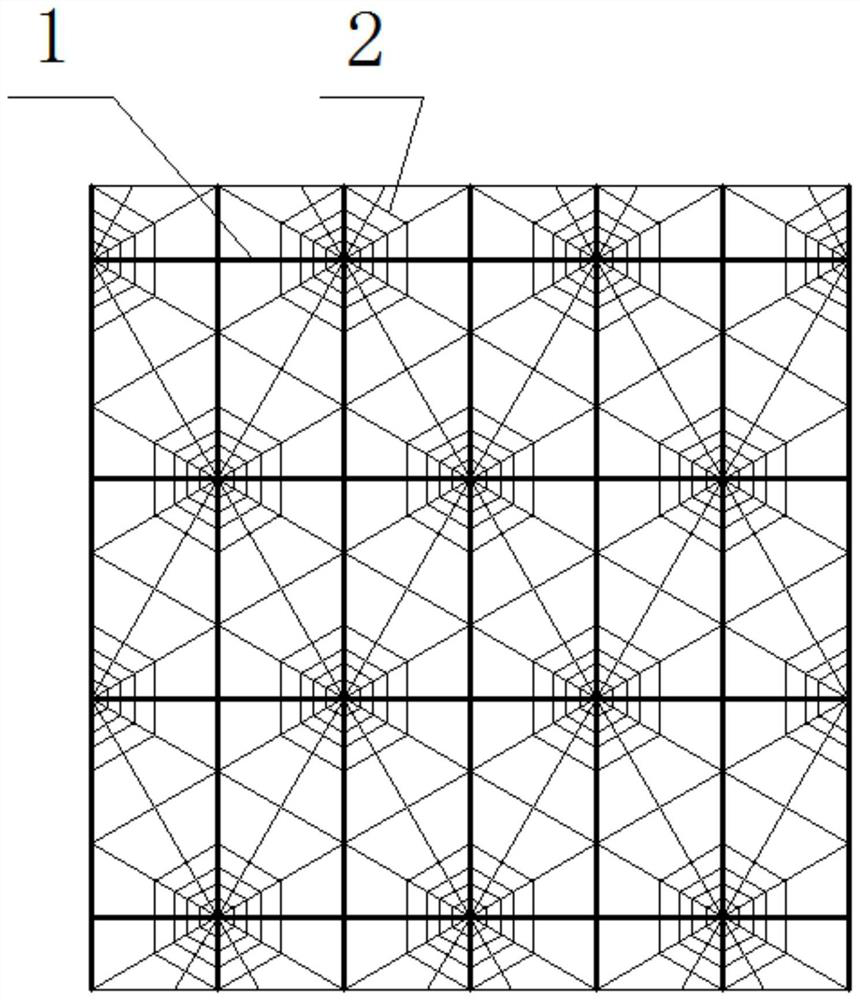

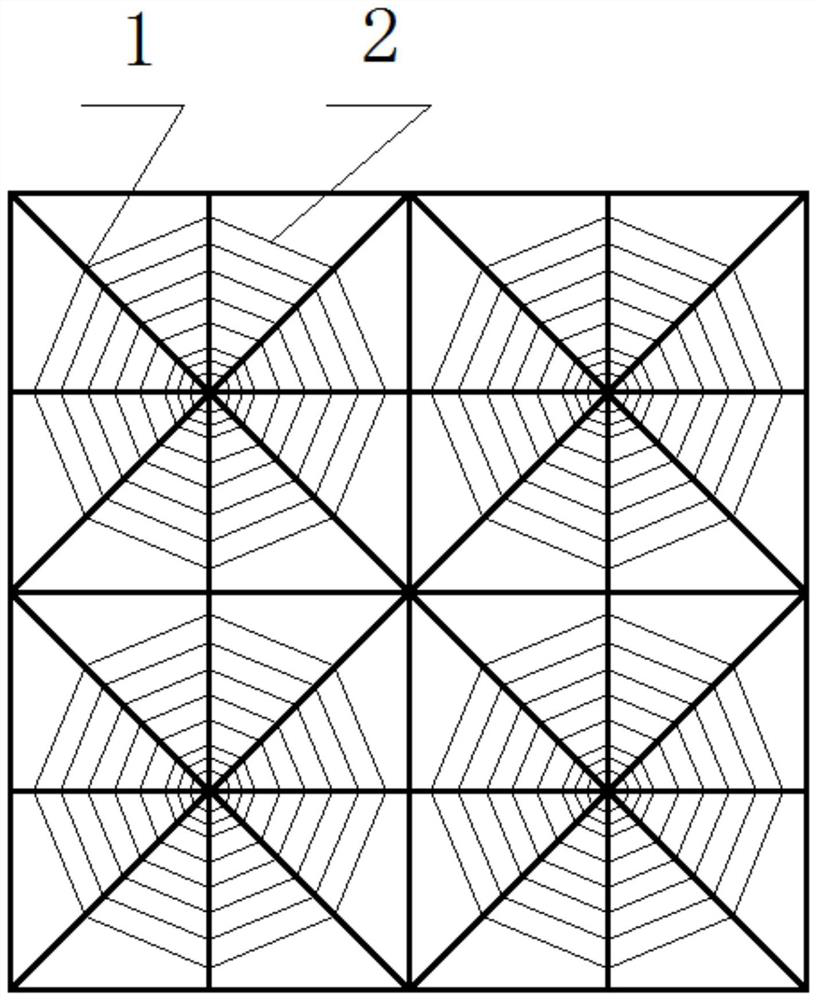

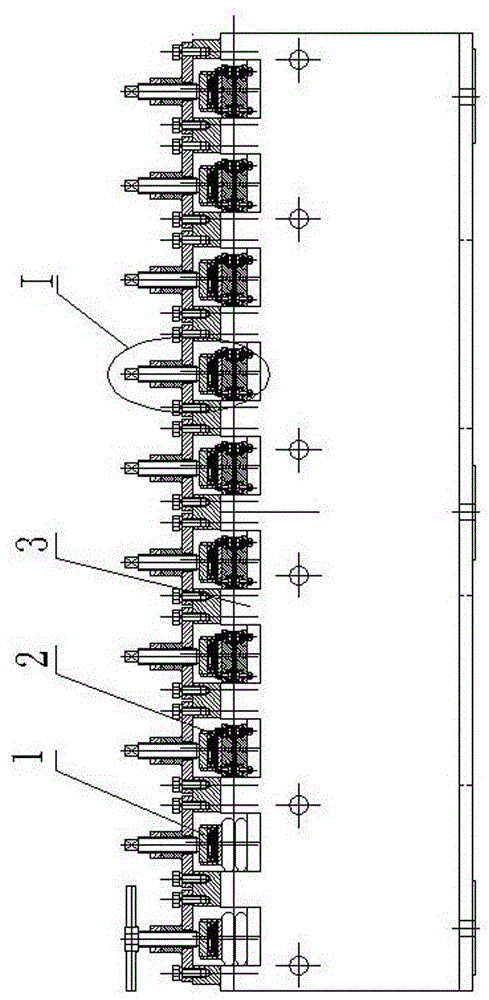

Biological filler and mounting structure and method thereof

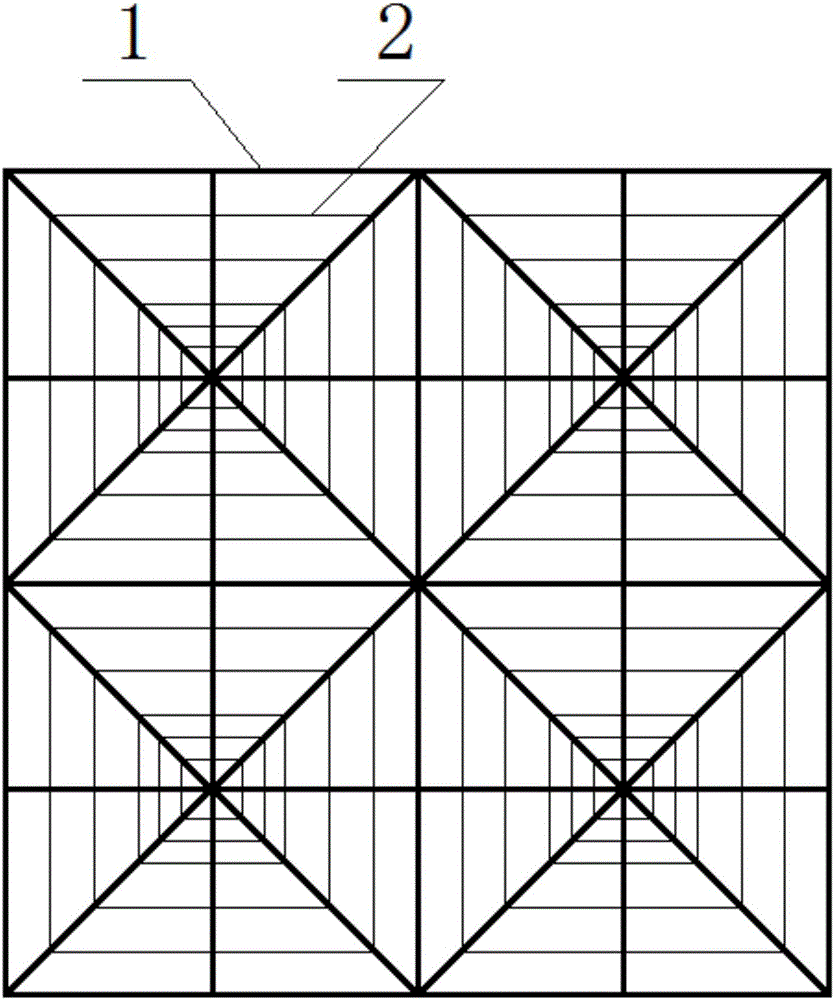

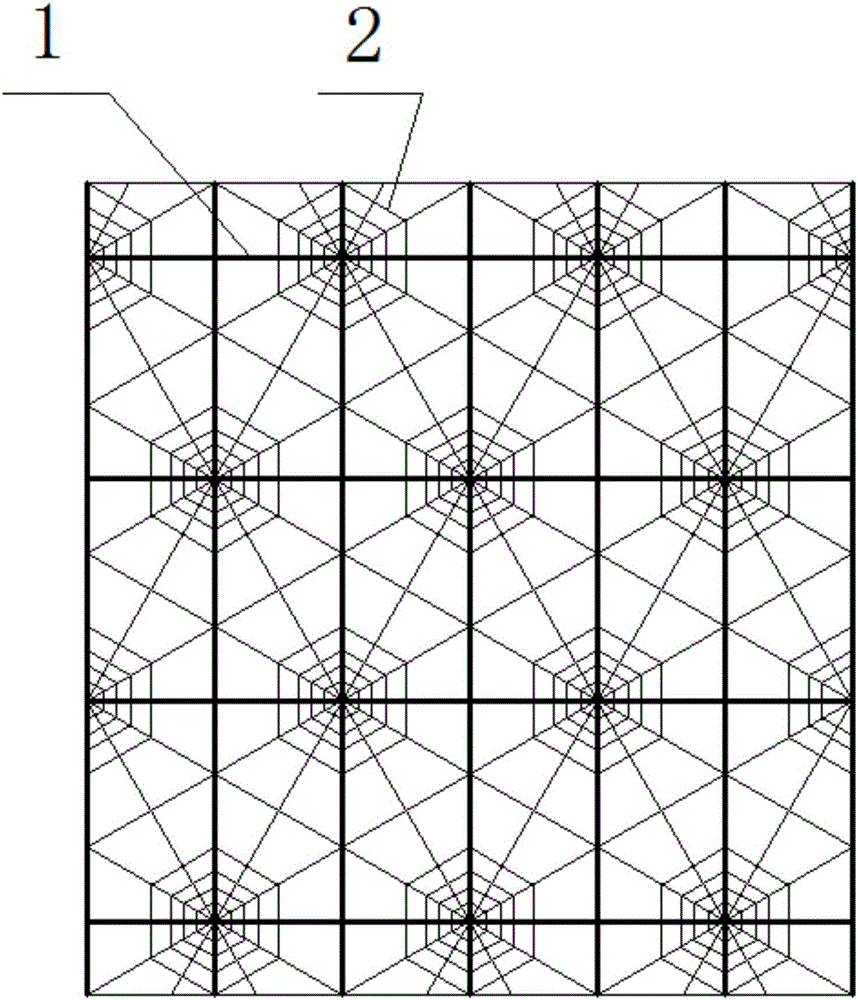

ActiveCN106115903AReduce dosageRapid film growthTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesEngineeringBiological membrane

Disclosed are a biological filler and a mounting structure and a method thereof. The biological filler comprises: a plurality of film-filling units arranged in a matrix; each of the film-filling units comprises a plurality of skeletons and film-mesh wires. The skeletons are crossed to constitute the center of each film-filling unit. The film-mesh wires are distributed on the skeletons from the center to the periphery sparsely and densely, so that each of the film-filling units forms a spider-like structure. The invention also provides the installation structure and the installation method of the biological filler. The biological filler in the invention adopts the bionic netting structure, has the advantages of small size, dense order, fast growth of biofilm and large amount of biological adhesion, and can be produced by the textile method. Production cost and investment can be reduced. The installation structure of the biological filler is simple structure, the installation method is convenient and quick to ensure the spatial stability of filler, pollutants in the water can be captured as much as possible, and sewage treatment efficiency is high.

Owner:北京华夏大禹科技有限公司

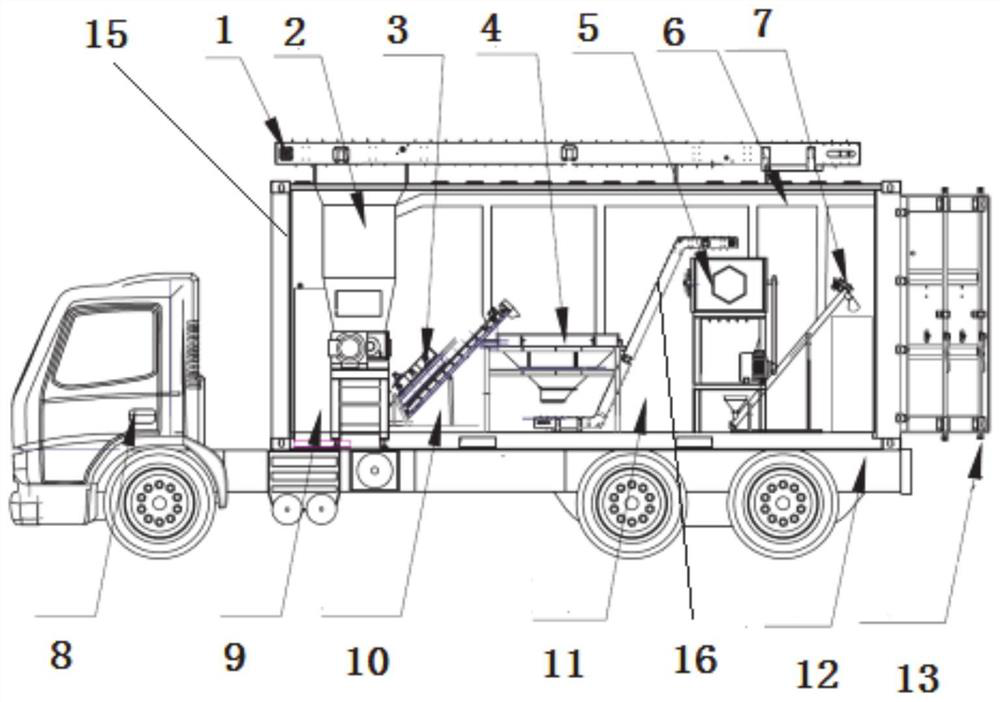

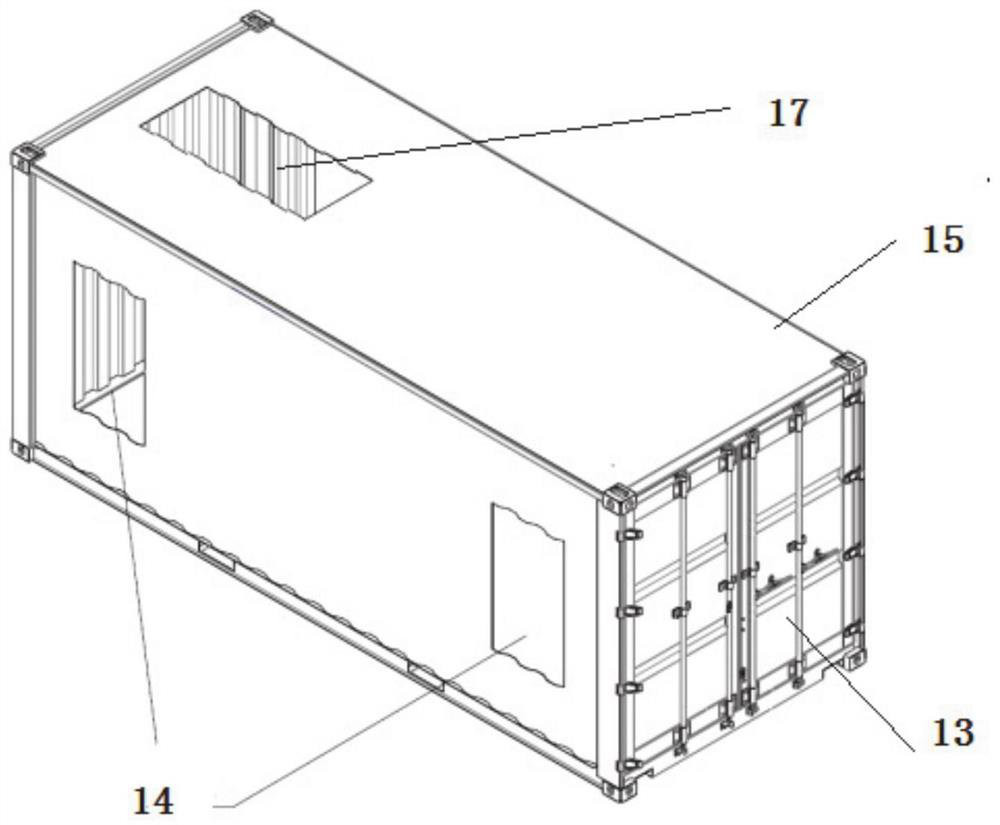

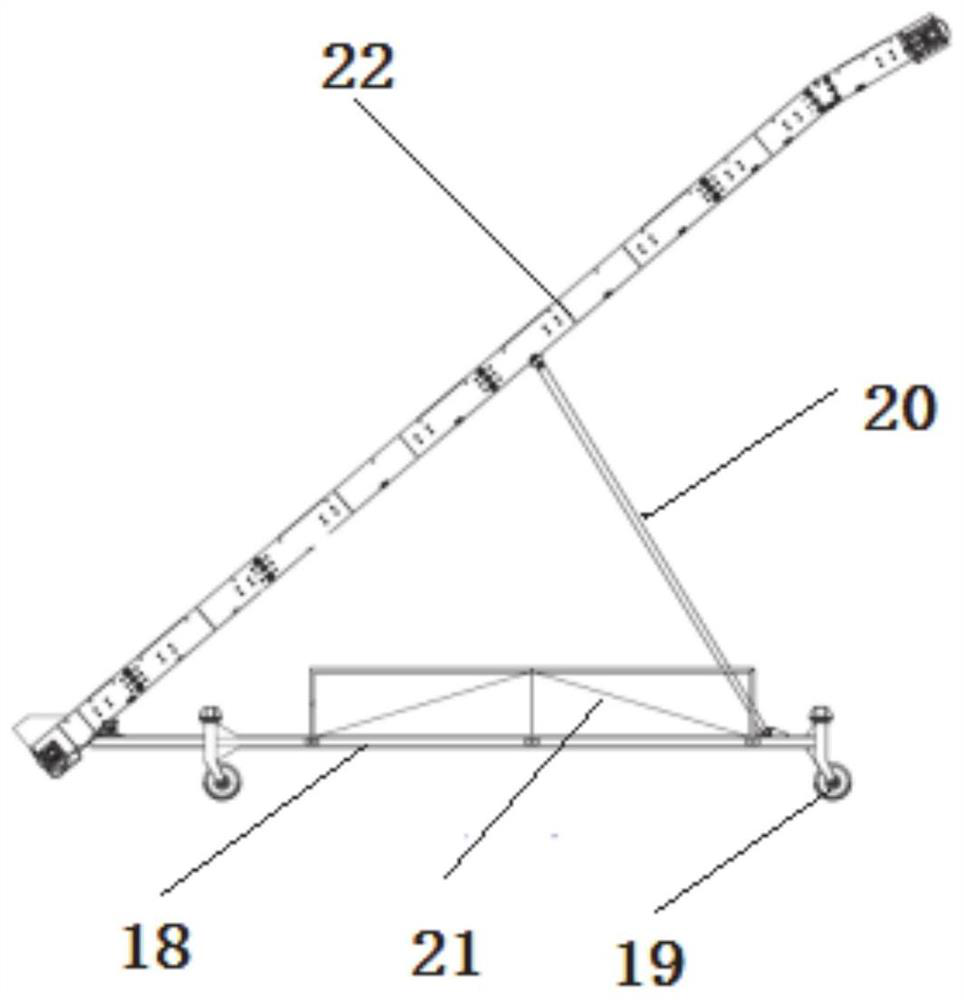

Movable industrial solid waste fiber composite material treatment system, working method and application

ActiveCN113856876AEffective control of floor spaceReduce construction costsSolid materialGrain treatmentsWaste collectionFibrous composites

The invention discloses a movable industrial solid waste fiber composite material treatment system, a working method and application. The problems that in the prior art, waste treatment cost is high, and on-site treatment cannot be achieved are solved. The movable industrial solid waste fiber composite material treatment system has the beneficial effects that cross-region transportation can be achieved, on-site treatment and waste collection can be achieved, and cost is reduced. According to the specific scheme, the movable industrial solid waste fiber composite material treatment system comprises a tray, the tray is installed on a walking mechanism so that the treatment system can move, the tray supports at least one set of crushing units so as to crush materials, the crushing particle sizes of the crushing units are different, a screening unit is arranged behind the at least one set of crushing units so as to screen the crushed materials, a magnetic separation unit is further arranged between the at least one set of crushing units and the adjacent screening unit so as to separate metal in the crushed materials, and the screening unit and the magnetic separation unit are both supported through the tray.

Owner:CRRC SHANDONG CO LTD

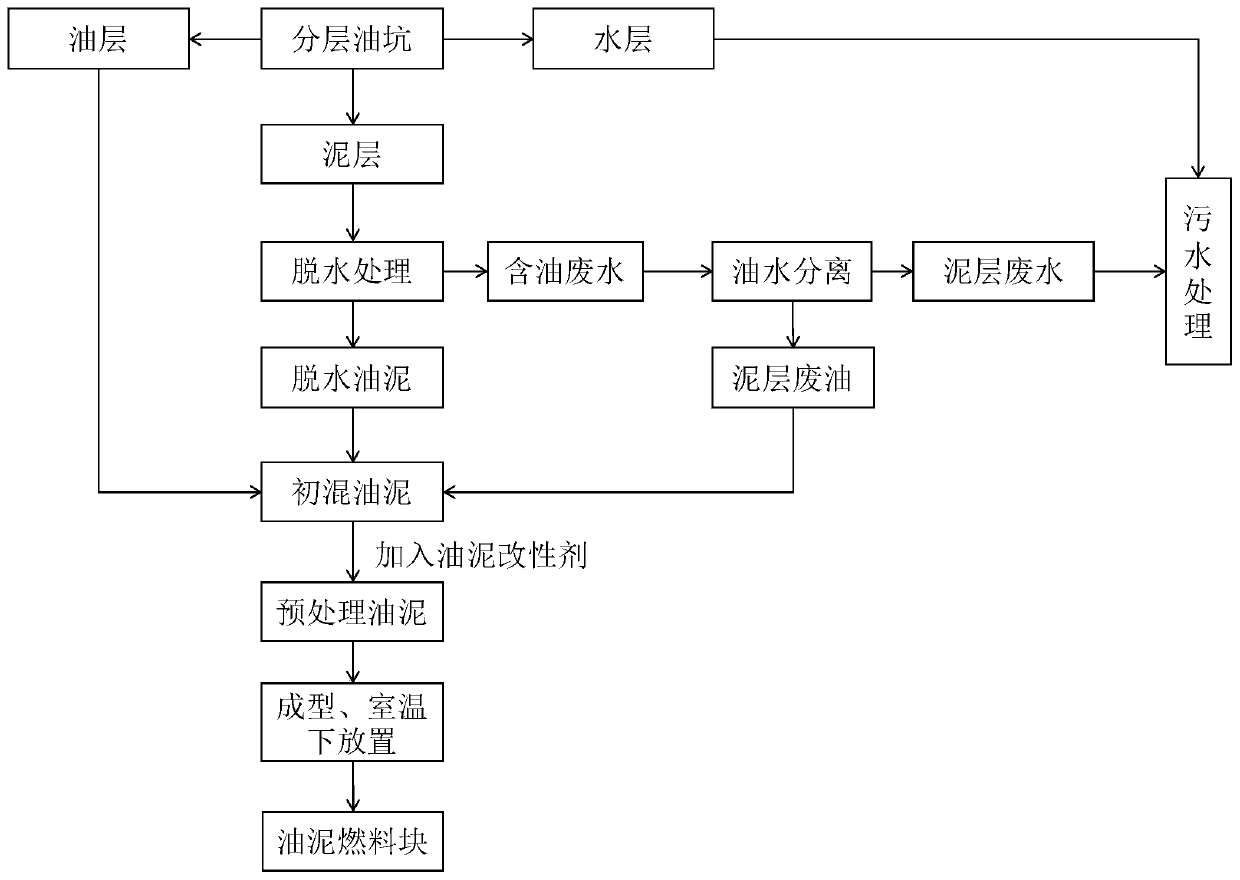

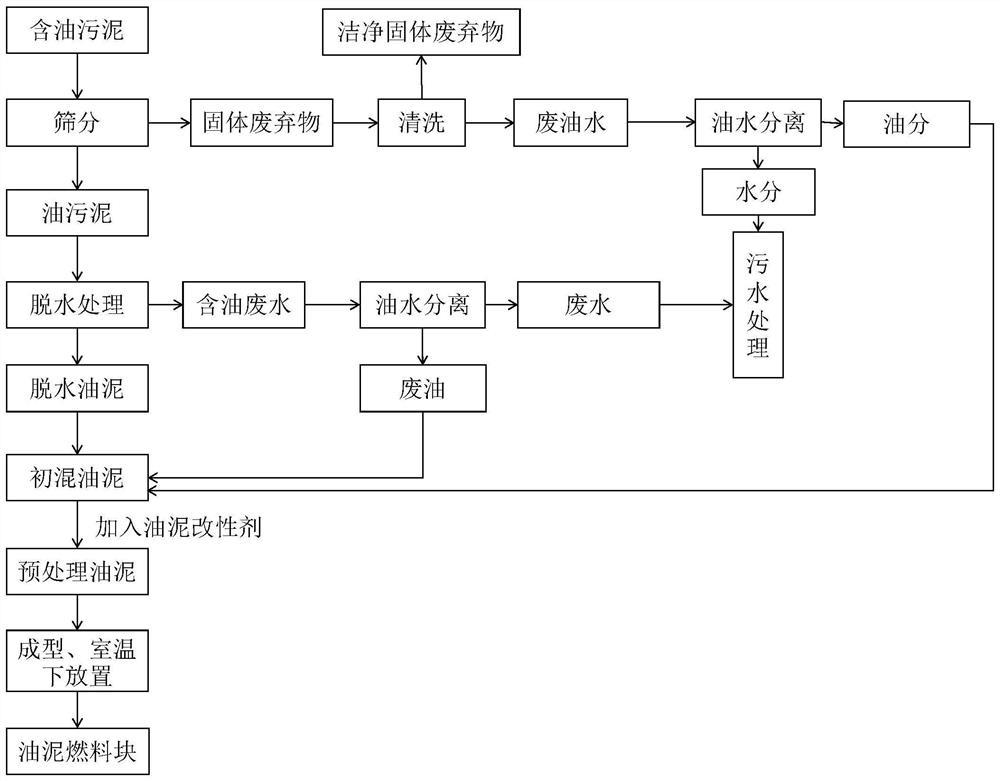

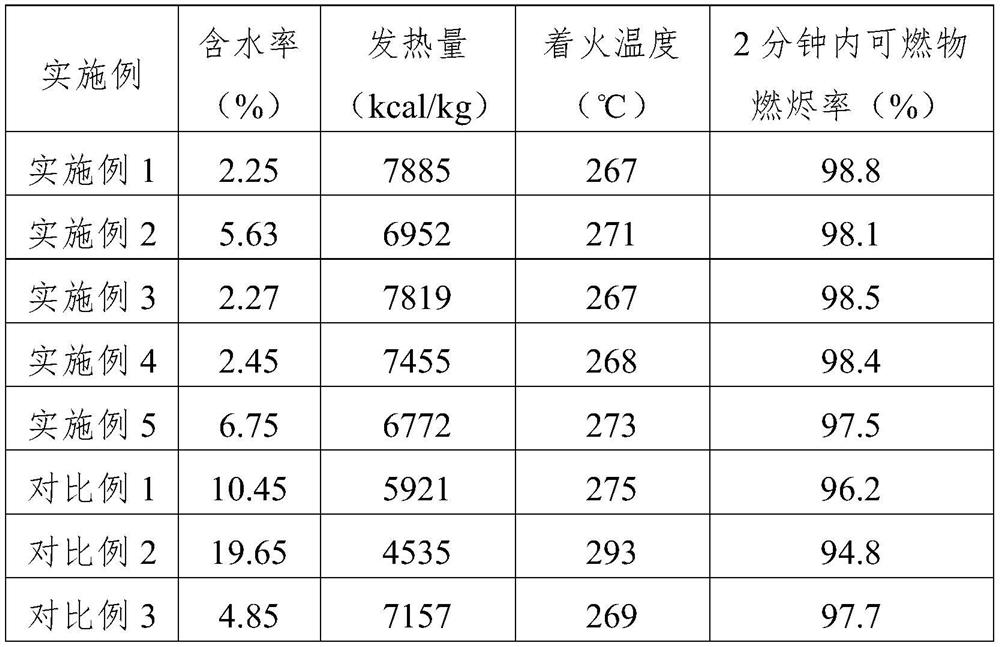

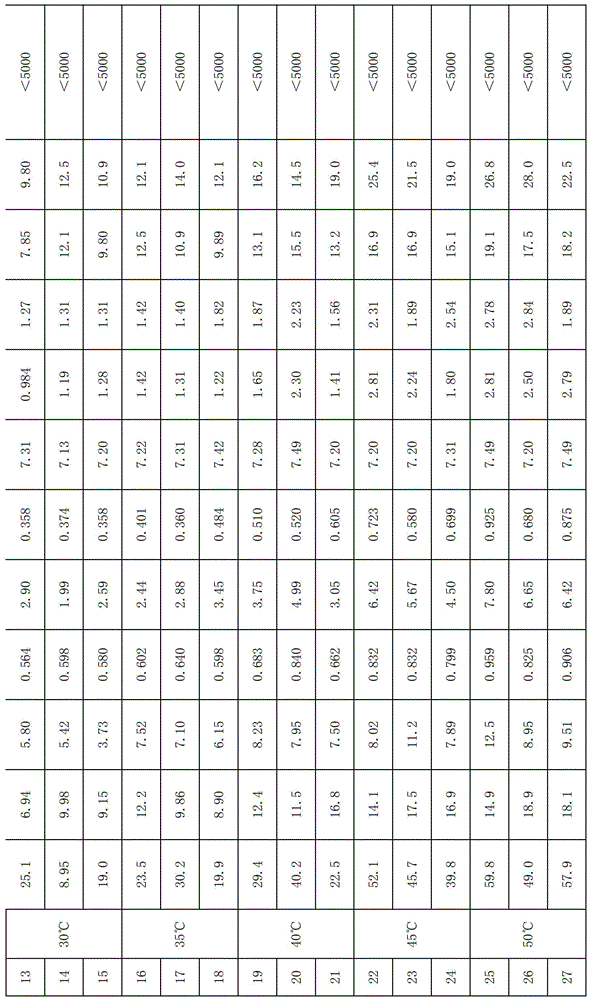

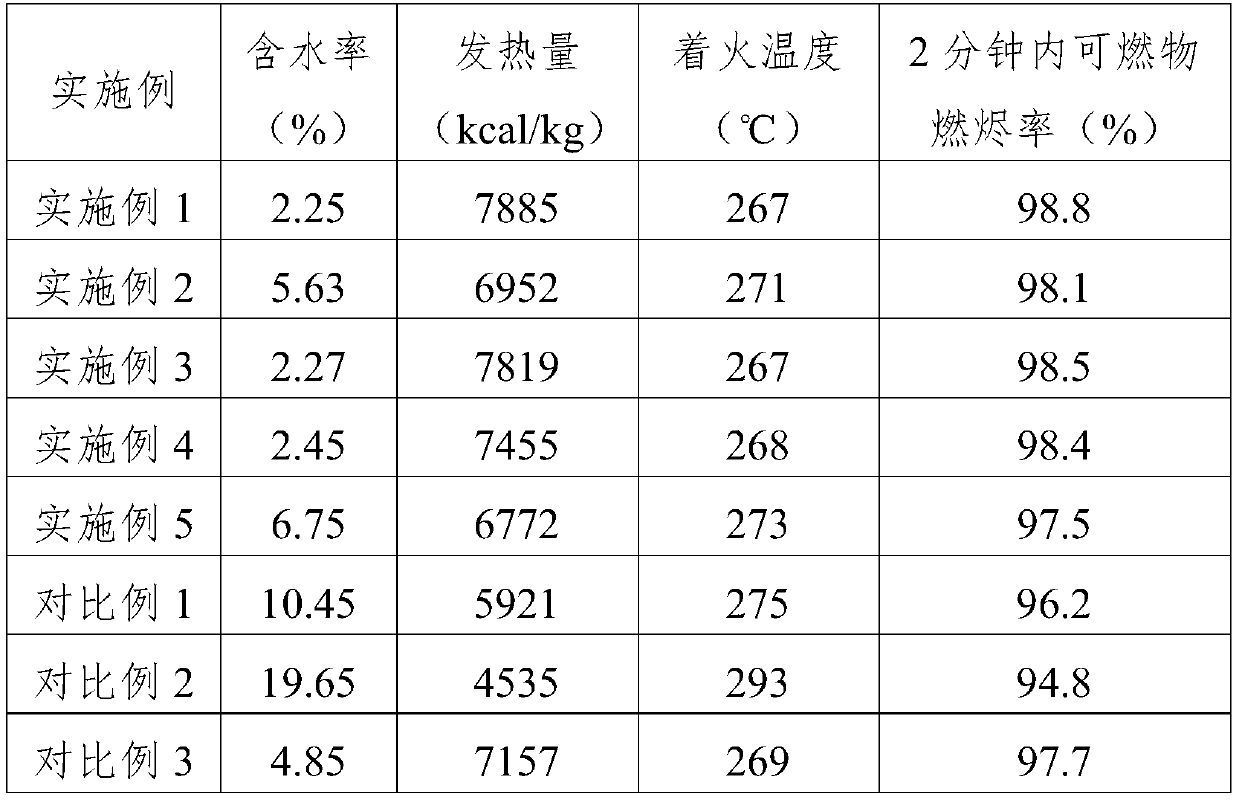

Stratified oil pit harmless treatment method and oil sludge fuel block prepared thereby

ActiveCN110255839AEfficient separationReduce pollutionSludge treatmentBiofuelsSodium BentoniteWaste oil

The invention relates to a stratified oil pit harmless treatment method and an oil sludge fuel block prepared thereby. The method includes: collecting an oil layer, a water layer and a sludge layer from a stratified oil pit; acquiring dehydrated oil sludge and oily wastewater from the sludge layer, and performing oil-water separation on the oily wastewater to obtain sludge layer waste oil and wastewater, and then carrying out sewage treatment on the water layer and sludge layer wastewater; mixing the oil layer, the dehydrated oil sludge and the sludge layer waste oil to obtain preliminary mixed oil sludge, adding an oil sludge modifier and mixing the substances evenly to obtain pretreated oil sludge, wherein the oil sludge modifier includes, by mass percentage, 50-66.5% of an auxiliary material, 13-27.5% of a curing agent, 3-10% of calcium oxide, 3-15% of bentonite and 0.3-5% of cement; molding the pretreated oil sludge, and then placing the product at room temperature, thus obtaining the oil sludge fuel block. The method provided by the invention can realize harmless, clean and recycling treatment of oil sludge in the stratified oil pit, and the content of leached heavy metals and contained dioxin and other substances in the combustion product fly ash of the prepared oil sludge fuel block is extremely low.

Owner:哈尔滨工大环能科技有限公司

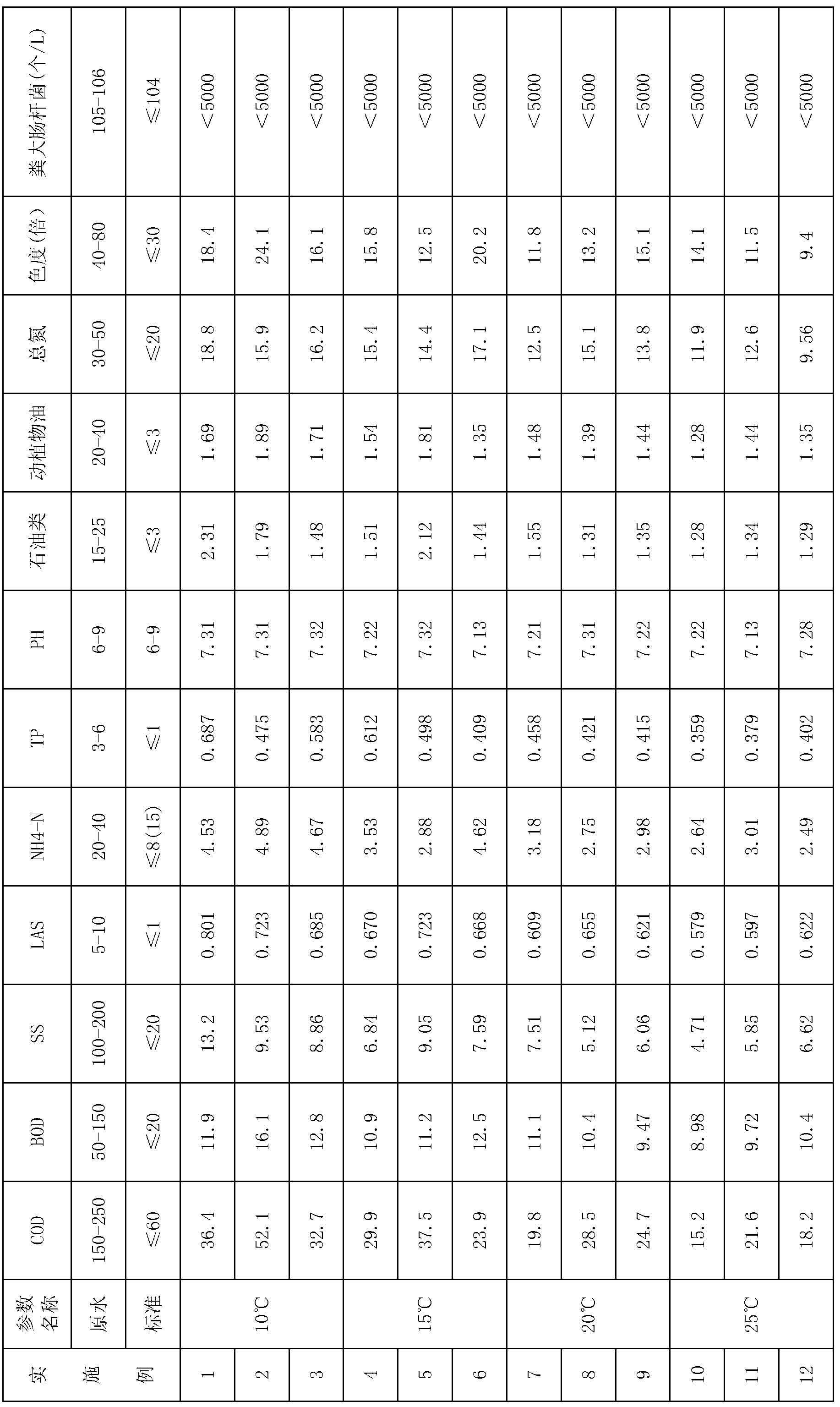

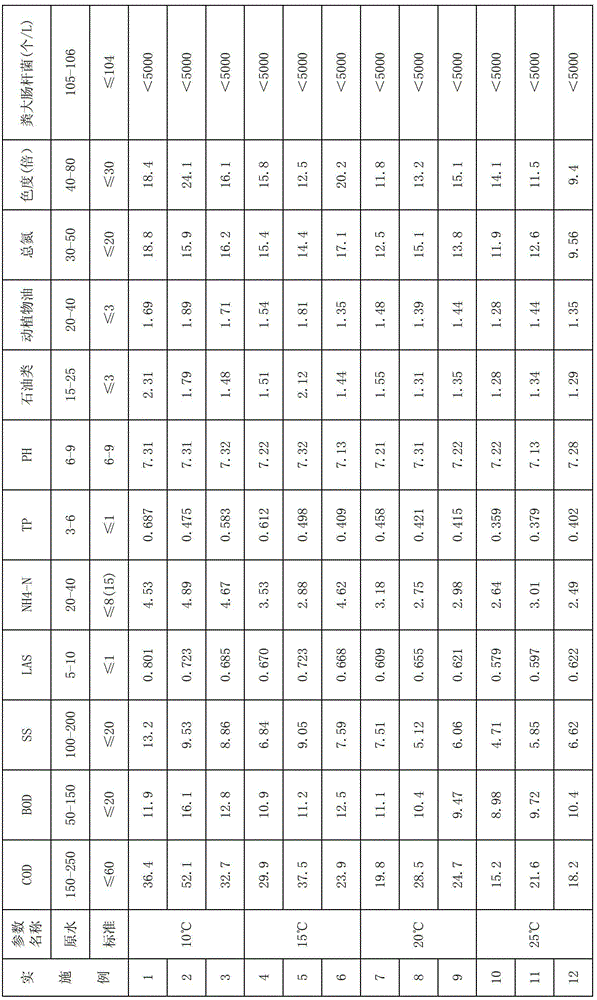

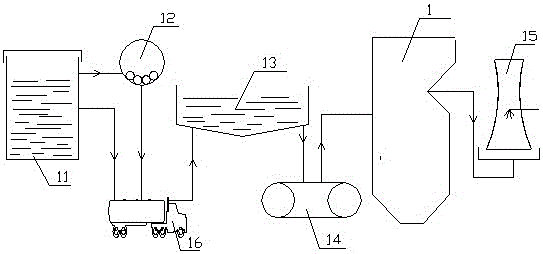

Thermal insulation biological medium oxidation treatment method for domestic sewage

ActiveCN103241843ASmall processing investmentLow running costTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesThermal insulationWater quality

The invention discloses a thermal insulation biological medium oxidation treatment method for domestic sewage. The thermal insulation biological medium oxidation treatment method for domestic sewage comprises the following steps of: (1) removing solid impurities in the domestic sewage; (2) carrying out oxidation and nitrogen and phosphorus removal treatment on the domestic sewage treated by the step (1) by virtue of microorganism medium, so as to remove organic matters; and (3) feeding the domestic sewage treated by the step (2) into a denitrification tank added with a carbon source to be denitrified, wherein temperature of the microorganism medium in the step (2) is maintained to be 10-50 DEG C. The thermal insulation biological medium oxidation treatment method for the domestic sewage has the advantages that investment on treatment of the domestic sewage is small, operating cost is low, maintenance and management are simple, operation is stable, no secondary pollution is produced, the thermal insulation biological medium oxidation treatment method for the domestic sewage is not influenced by regions and seasons and effluent quality can meet water quality standard of landscape surface water.

Owner:ANHUI MEIZIRAN ENVIRONMENTAL TECH

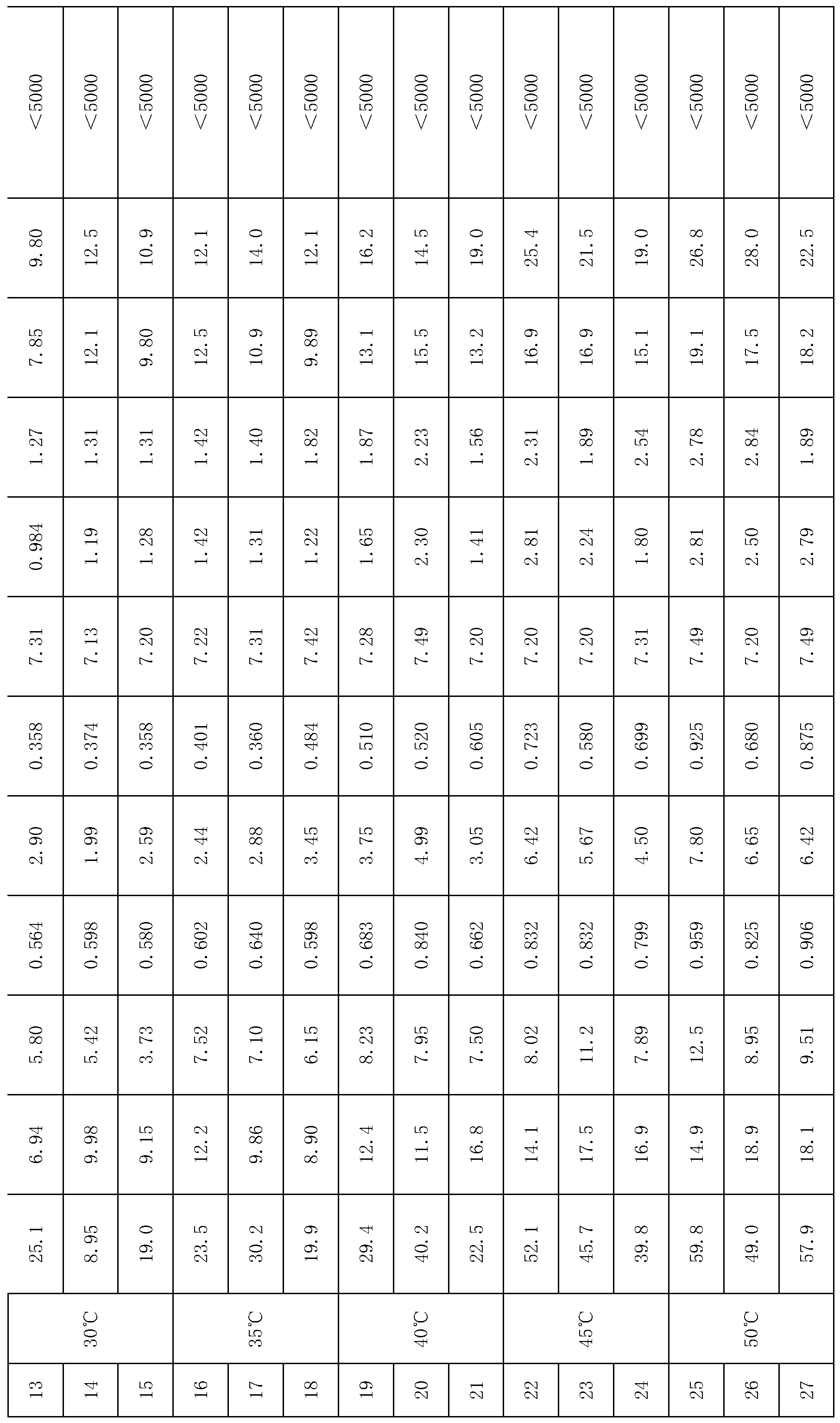

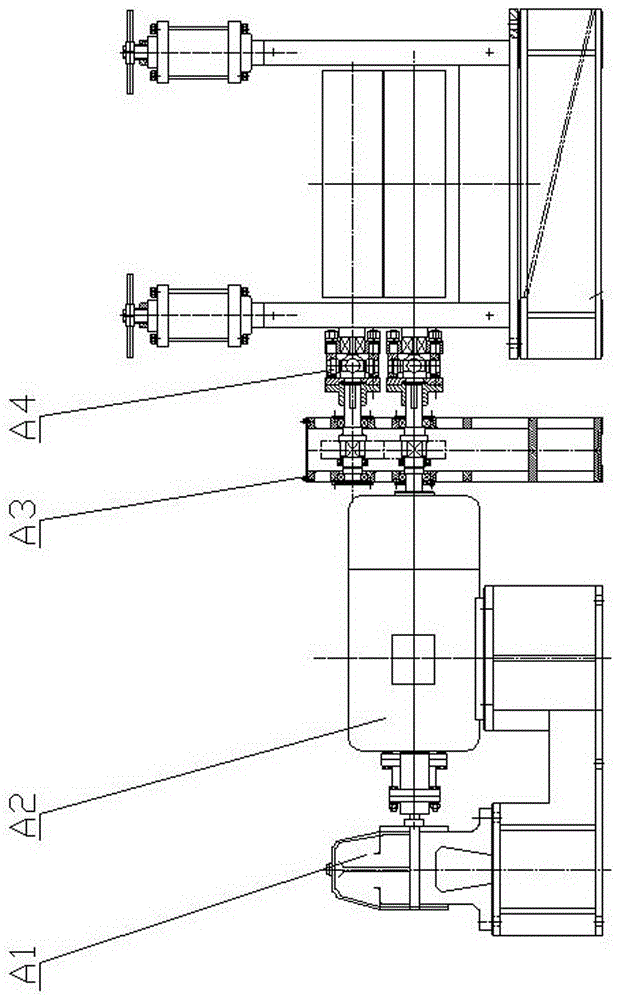

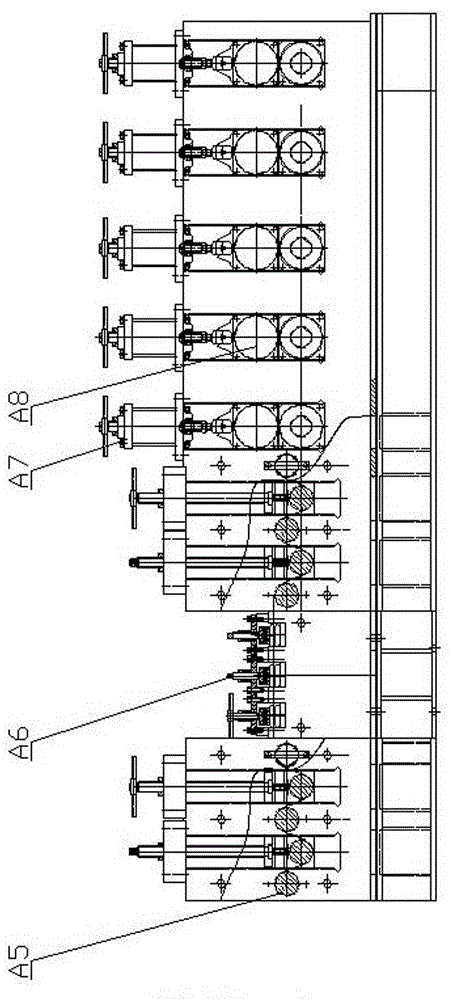

A complete set of acid-free descaling equipment for steel strip surface and descaling method thereof

ActiveCN104815857BCompletely eradicate pollutionEradicate pollutionWork treatment devicesMetal rolling arrangementsStrip steelSmall footprint

The invention provides a strip steel surface acid-free descaling complete device which meets the strip steel surface descaling. A steel strip undergoes treatment through supporting devices such as two groups of multi-roll toothed descalers, a green fabric dust-free polishing machine and an automatic balance steel brushing machine, so that oxide scale on the surface of a steel plate is thoroughly eliminated, and the requirements of cold rolling of strip steel and strip steel surface galvanizing are met. The strip steel surface acid-free descaling complete device has the advantages of being free of acid consumption, noise and dust and eliminating the pollution to the human body, the environment, devices and rivers caused by acid pickling. The strip steel surface acid-free descaling complete device does not consume coal power for heating and high-pressure water and is low in cost, small in investment and occupied space and good in comprehensive benefit.

Owner:桂源

A method for treating coal dry distillation wastewater

ActiveCN108147612BSmall processing investmentEfficient degreasingFatty/oily/floating substances removal devicesWater contaminantsChemical industryDistillation

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A biological filler and its installation structure and method

ActiveCN106115903BReduce dosageRapid film growthTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesBiofilmSpider web

Owner:北京华夏大禹科技有限公司

A kind of multistage catalytic adsorption reactor

ActiveCN103007747BSimple structureSmall processing investmentDispersed particle separationActivated carbonSulfur

The invention discloses a multi-stage catalyzed sorption reactor which comprises a reactor body, catalyzed sorption beds, charging holes, discharge holes, gas inlets and a gas outlet, wherein the catalyzed sorption beds are fixed in the reactor body to divide the interior of the reactor body into independent catalyzed sorption spaces; the discharge holes are formed in the reactor body on the upper surfaces of the catalyzed sorption beds; the charging holes are formed in the reactor body in the middles of the independent catalyzed sorption spaces formed by the upper surfaces of the catalyzed sorption beds; the gas inlets are formed in the reactor body on the lower surfaces of the catalyzed sorption beds; and the gas outlet is formed at the upper part of the reactor body. The charging holes and the discharge holes are used for filling high-efficiency converted-sorption activated carbon desulfurizing agents; acid gas enters the reactor body through the gas inlets, and conducts sorption and catalysis with the high-efficiency converted-sorption activated carbon desulfurizing agents through the catalyzed sorption beds; the high-efficiency converted-sorption activated carbon desulfurizing agents convert sulfur-bearing matters in the acid gas to simple sulfur, simple sulfur is sorbed in micropores of a catalyst; and desulfurized tail gas is discharged out of the reactor body through the gas outlet of the reactor body.

Owner:JIANGSU HENGXIN ENERGY TECH

Non-layered oil pit harmless treatment method and oil sludge fuel block prepared by same

The invention relates to a non-stratified oil pit harmless treatment method and an oil sludge fuel block prepared by the non-stratified oil pit harmless treatment method. The method comprises the following steps: screening homogeneous-phase oily sludge to remove solid wastes to obtain oily sludge; carrying out dehydration treatment on the oily sludge to obtain dehydrated oil sludge and oily wastewater, and carrying out oil-water separation on the oily wastewater to obtain waste oil and wastewater; carrying out sewage treatment on the wastewater; mixing the dehydrated oil sludge with waste oil to obtain primarily mixed oil sludge, adding an oil sludge modifier, and uniformly mixing to obtain pretreated oil sludge; the oil sludge modifier comprises the following components in percentage by mass: 66.5% of an auxiliary material, 15-18% of a curing agent, 5-7% of calcium oxide, 8.5-9.5% of bentonite and 1-2.5% of cement, the pretreated oil sludge is placed at the room temperature after being formed, and the oil sludge fuel block is prepared. Harmless, clean and resourceful treatment of the oil sludge in the non-layered oil pit can be achieved, and the content of heavy metal leached from the combustion product fly ash of the prepared oil sludge fuel block and the content of dioxin and other substances contained in the combustion product fly ash are extremely low.

Owner:哈尔滨工大环能科技有限公司

Thermal insulation biological medium oxidation treatment method for domestic sewage

ActiveCN103241843BSmall processing investmentLow running costTreatment with anaerobic digestion processesTreatment with aerobic and anaerobic processesThermal insulationWater quality

The invention discloses a thermal insulation biological medium oxidation treatment method for domestic sewage. The thermal insulation biological medium oxidation treatment method for domestic sewage comprises the following steps of: (1) removing solid impurities in the domestic sewage; (2) carrying out oxidation and nitrogen and phosphorus removal treatment on the domestic sewage treated by the step (1) by virtue of microorganism medium, so as to remove organic matters; and (3) feeding the domestic sewage treated by the step (2) into a denitrification tank added with a carbon source to be denitrified, wherein temperature of the microorganism medium in the step (2) is maintained to be 10-50 DEG C. The thermal insulation biological medium oxidation treatment method for the domestic sewage has the advantages that investment on treatment of the domestic sewage is small, operating cost is low, maintenance and management are simple, operation is stable, no secondary pollution is produced, the thermal insulation biological medium oxidation treatment method for the domestic sewage is not influenced by regions and seasons and effluent quality can meet water quality standard of landscape surface water.

Owner:ANHUI MEIZIRAN ENVIRONMENTAL TECH

Non-stratified oil pit harmless treatment method and oil sludge fuel block prepared thereby

ActiveCN110255838AWide range of applicationsSmall processing investmentSolid fuelsWaste based fuelHeavy metalsSewage treatment

The invention relates to a non-stratified oil pit harmless treatment method and an oil sludge fuel block prepared thereby. The method includes: sieving homogeneous oily sludge to remove solid waste to obtain oil sludge; conducting dehydration treatment on the oil sludge to obtain dehydrated oil sludge and oily wastewater, and performing oil-water separation on the oily wastewater to obtain waste oil and wastewater; conducting sewage treatment on the wastewater; mixing the dehydrated oil sludge and waste oil to obtain preliminary mixed oil sludge, adding an oil sludge modifier and mixing the substances evenly to obtain pretreated oil sludge, wherein the oil sludge modifier includes, by mass percentage, 50-66.5% of an auxiliary material, 13-27.5% of a curing agent, 3-10% of calcium oxide, 3-15% of bentonite and 0.3-5% of cement; molding the pretreated oil sludge and then placing the product at room temperature, thus obtaining an oil sludge fuel block. The method provided by the invention can realize harmless, clean and recycling treatment of oil sludge in non-stratified oil pit, and the content of heavy metals leached out of the combustion product fly ash of the prepared oil sludge fuel block and contained dioxin and other substances is very low.

Owner:哈尔滨工大环能科技有限公司

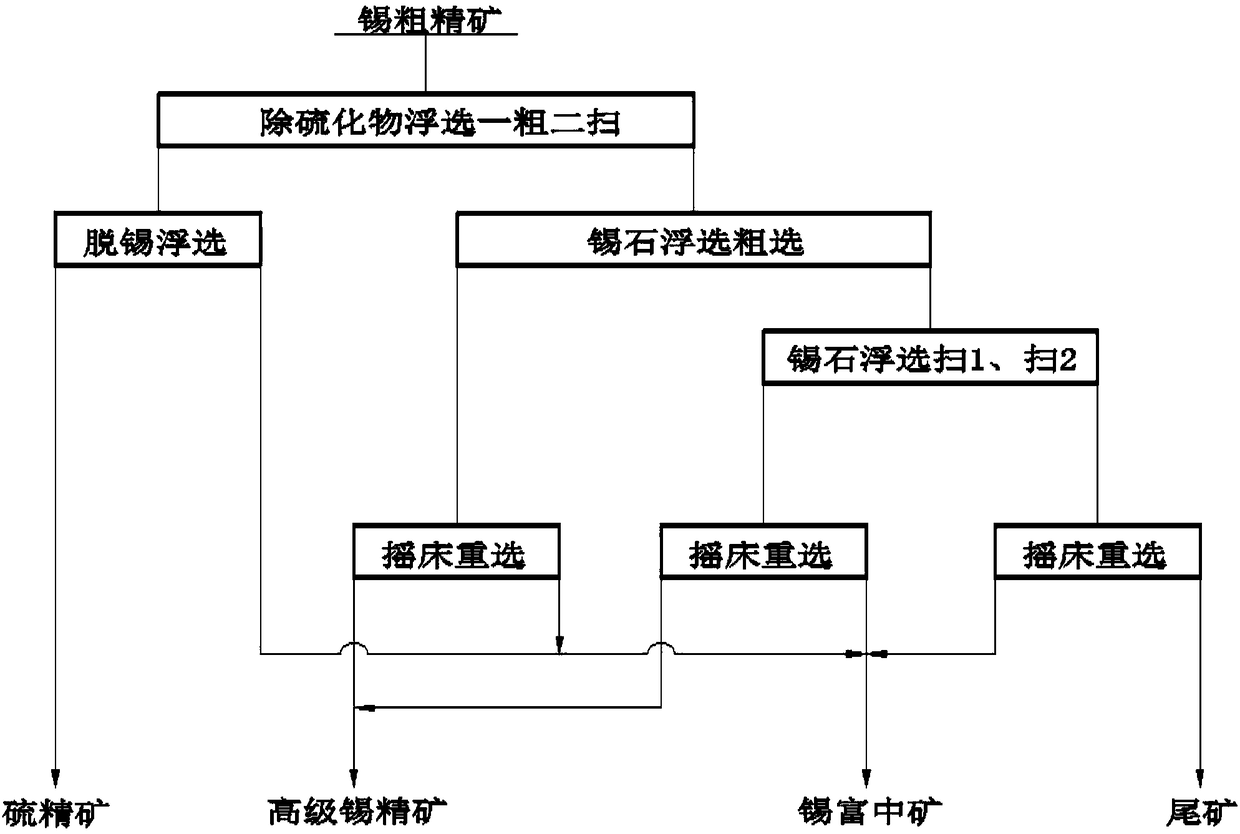

A kind of beneficiation and beneficiation process of tin sulfide ore coarse concentrate

The invention relates to an ore concentration technique for tin sulphide ore rough concentrate. The technique comprises the following steps of grinding of tin rough concentrate, sulfide flotation, cassiterite flotation, cassiterite foam flotation and tailing re-flotation. The ore concentration technique combines full ore grinding, sulfur flotation, tin flotation, table concentration and scavenging and is an ore separation method capable of sufficiently and effectively recovering valuable resources, such as valuable metal tin and sulphur (copper) elements, in tin rough concentrate and achieving separation and enrichment of the valuable resources under the condition that the mineral substance composition is not changed. By adoption of technique combining full ore grinding, sulfide flotation, sulfide detinning flotation, cassiterite flotation, cassiterite foam flotation, and table concentration and scavenging of tailings, concentration of the tin sulphide ore rough concentrate is perfected, and the recycling rate of tin metal is increased.

Owner:YUNNAN TIN

A method for oil sludge separation-gasification resource utilization

ActiveCN105693055BRealize comprehensive utilizationAchieve recyclingSludge treatmentSpecific water treatment objectivesCoal waterHigh energy

Owner:SHAANXI YANCHANG PETROLEUM GRP

Strip steel surface acid-free descaling complete device and descaling method thereof

ActiveCN104815857AGood effectCompletely eradicate pollutionWork treatment devicesMetal rolling arrangementsSheet steelSmall footprint

The invention provides a strip steel surface acid-free descaling complete device which meets the strip steel surface descaling. A steel strip undergoes treatment through supporting devices such as two groups of multi-roll toothed descalers, a green fabric dust-free polishing machine and an automatic balance steel brushing machine, so that oxide scale on the surface of a steel plate is thoroughly eliminated, and the requirements of cold rolling of strip steel and strip steel surface galvanizing are met. The strip steel surface acid-free descaling complete device has the advantages of being free of acid consumption, noise and dust and eliminating the pollution to the human body, the environment, devices and rivers caused by acid pickling. The strip steel surface acid-free descaling complete device does not consume coal power for heating and high-pressure water and is low in cost, small in investment and occupied space and good in comprehensive benefit.

Owner:桂源

Recycling method of organic bentonite for organic wastewater treatment

ActiveCN103007909BSmall processing investmentReduce secondary pollutionOther chemical processesCombustible gas purificationSodium BentoniteElectrolysis

Owner:无锡智慧兴宜信息技术有限公司

A sludge drying and incineration system relying on thermal power plants

ActiveCN104628237BSave money on deep dryingDecompose thoroughlyCombination devicesSludge treatment by de-watering/drying/thickeningHandling systemThermoelectric Power Plants

The invention discloses a sludge drying incineration system based on a thermal power plant. The system comprises a sludge drying system and a sludge mixing incineration system, wherein the sludge drying system comprises a heat supply system, a feeding system, a paddle type sludge dryer, a dead steam treating system, a dead steam recycling system and a dried sludge collecting and handling system; and the sludge mixing incineration system comprises a dried sludge mixing system and a dried sludge incineration system. According to the sludge drying incineration system based on the thermal power plant, sludge is dried through high-temperature steam produced by a boiler of the thermal power plant; the dried sludge is incinerated and the resulting heat is used for producing steam; the whole process is free of pollutant; therefore, an effective way is actually developed for recycling the wastes and treating wastes with the wastes, the social and environmental benefits are obvious, and a feasible way is provided for harmless handling, reducing handling and recycling of sludge.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

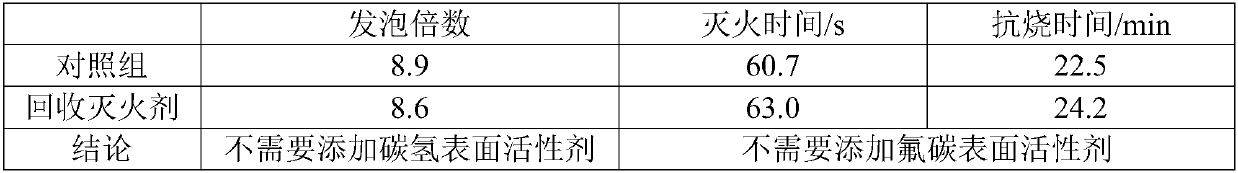

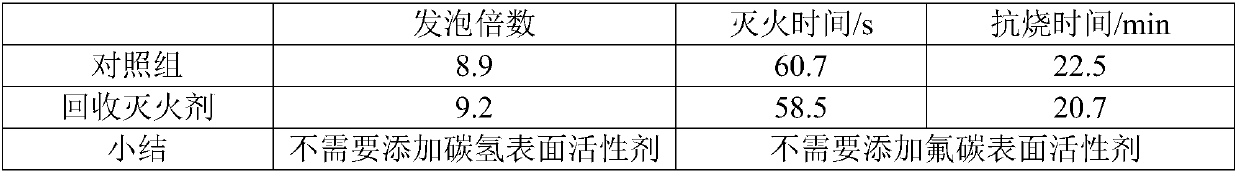

Regenerating method for non-fusible aqueous film-forming foam fire extinguishing agent

The invention relates to a regenerating method for a non-fusible aqueous film-forming foam fire extinguishing agent, and mainly solves the problem that in a non-fusible aqueous film-forming foam fireextinguishing agent in the prior art, water-soluble operation is difficult to remove. The regenerating method for the non-fusible aqueous film-forming foam fire extinguishing agent comprises the following steps: refrigerating the failed 6% type non-fusible aqueous film-forming foam fire extinguishing agent into solid, pulverizing the solid into slag, and centrifuging the slag for 3-15 minutes in acentrifuging machine, wherein filter residue is an aqueous solution of water-soluble macromolecules. A certain amount of water is added in 3% type non-fusible aqueous film-forming foam fire extinguishing agent, and regeneration on the 3% type non-fusible aqueous film-forming foam fire extinguishing agent is carried out as regeneration on the 6% type non-fusible aqueous film-forming foam fire extinguishing agent. According to a prepared mode for the foam fire extinguishing agent, a required amount of water is added in filtrate, and thus, the non-fusible aqueous film-forming foam fire extinguishing agent is regenerated into 3% or 6% type aqueous film-forming foam fire extinguishing agent. By the technical scheme, the problem is solved well. The regenerating method for the non-fusible aqueous film-forming foam fire extinguishing agent can be used for regeneration of the non-fusible aqueous film-forming foam fire extinguishing agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

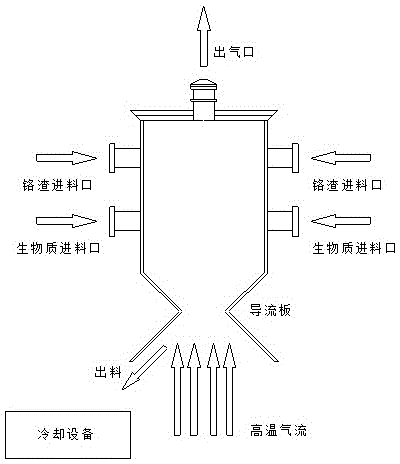

A Fluidized Bed Type Chromium Slag Pyrolysis Harmless Technology

The invention is a fluidized bed type chromium slag pyrolysis harmless process, which is characterized in that: the biomass and the chromium slag are put into the high temperature fluidized bed pyrolysis furnace respectively, and the biomass is rapidly melted and pyrolyzed in the process And release a large amount of pyrolysis gas to reduce Cr(VI). At the same time, the pyrolysis residual carbon adheres to the surface of the chromium slag during the fluidization process to protect the reduced Cr(III) in the chromium slag from secondary oxidation. The chromium slag also effectively catalyzes the pyrolysis gas generated to avoid the generation of a large amount of highly polluting tar gas. Compared with the traditional pyrolysis process, this process greatly shortens the residence time, and can generate energy tail gas with high calorific value at the same time, avoiding the treatment and disposal of tail gas.

Owner:光大理工环境技术研究院(青岛)有限公司

Anti-blocking compound fertilizer and preparation method thereof

The invention relates to an anti-blocking compound fertilizer and a preparation method of the compound fertilizer; the anti-blocking compound fertilizer is prepared by coating molasses alcohol waste liquid concentrate on the surface of the compound fertilizer; the organic substances in a molasses alcohol waste liquid are fully used for covering the surface of the granulated fertilizer, so that the fertilizer salt base is avoided being separated out, and the double effects of enveloping and preventing blocking can be achieved; meanwhile, the mineral elements in the molasses alcohol waste liquid is fully used for preparing the fertilizer and can be absorbed by crops, so that the double effects of environmental management and refuse reclamation can be achieved; and the method opens a new way for the comprehensive treatment of the molasses alcohol waste liquid.

Owner:广西洁能生物科技有限公司

Regenerating method for aqueous film-forming foam fire extinguishing agent

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com