Non-layered oil pit harmless treatment method and oil sludge fuel block prepared by same

A harmless treatment, non-layered technology, applied in chemical instruments and methods, fixed/solidified sludge treatment, fuel, etc., to achieve the effect of reducing treatment load, good effect and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

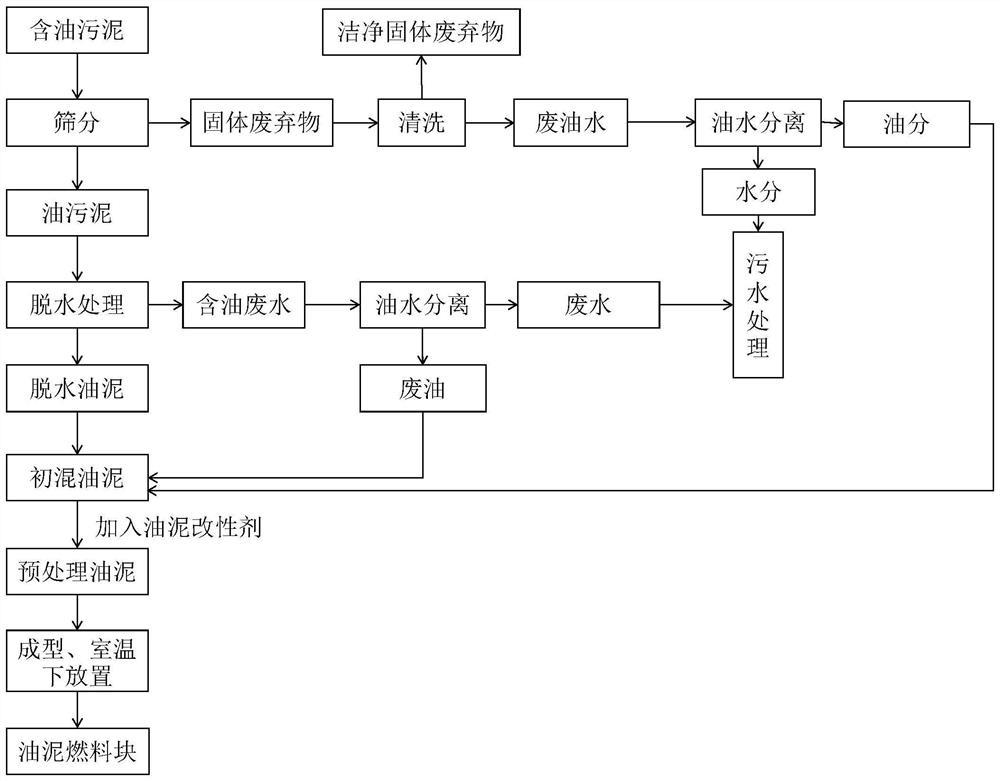

Method used

Image

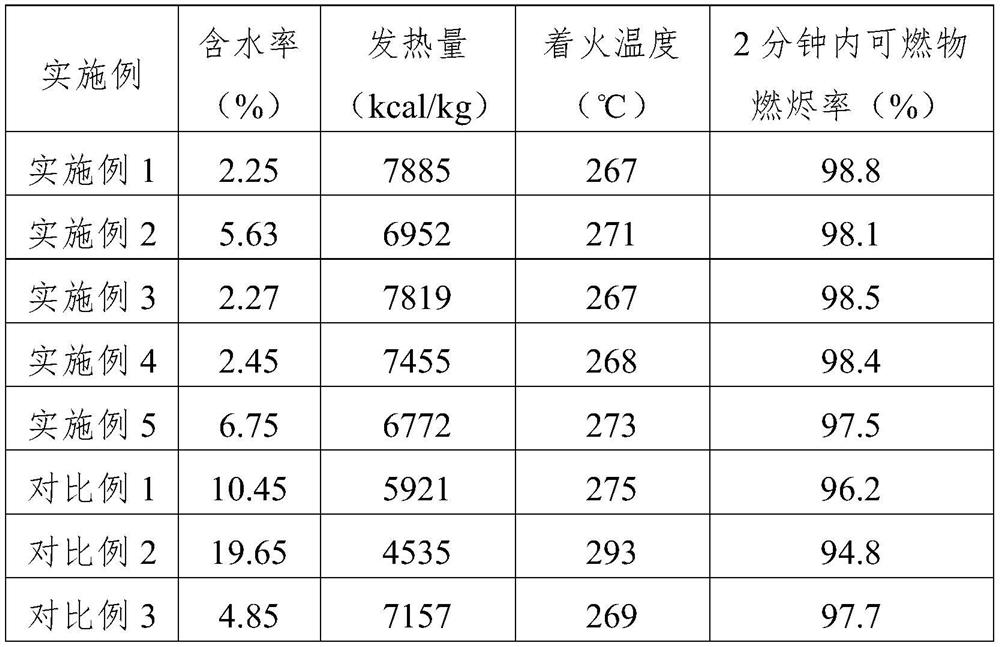

Examples

Embodiment 1

[0065]① Screening the oily sludge in the non-stratified oil pit to remove solid waste to obtain oily sludge; dewatering the obtained oily sludge to obtain oily wastewater and dewatered oily sludge with a moisture content of 15%, and then The obtained oily waste water is separated from oil and water to obtain waste oil and waste water, and the obtained waste water is subjected to sewage treatment.

[0066] 2. Mix the dewatered sludge in step ① and the waste oil evenly to obtain a preliminary mixed sludge with an oil content of 40%, then add an sludge modifier to the preliminary mixed sludge and mix evenly to obtain a pretreated sludge ; wherein, the mass ratio of the initially mixed sludge and the sludge modifier is 100:20; the sludge modifier is composed of 66.5% of auxiliary materials (straw), 16.5% of curing agent, 66.5% of calcium oxide by mass percentage. %, bentonite 9% and cement 2%; the curing agent is composed of methacryloyloxyethyl trimethyl ammonium chloride 40%, di...

Embodiment 2

[0070] Embodiment 2 is basically the same as Embodiment 1, except that:

[0071] In step ②, the sludge modifier is composed of 50% of auxiliary materials (straw), 27% of curing agent, 6% of calcium oxide, 12% of bentonite and 5% of cement by mass percentage; the curing agent is composed of 5% by mass Percentage of methacryloyloxyethyltrimethylammonium chloride 35%, dimethyldiallylammonium chloride 25%, acrylamide 25% and carboxymethyl cellulose 15%.

Embodiment 3

[0073] Embodiment 3 is basically the same as Embodiment 1, except that:

[0074] In step ②, the sludge modifier is composed of 66.5% of auxiliary materials (straw), 16.5% of curing agent, 6% of calcium oxide, 8.5% of bentonite, 2% of cement and 0.5% of oil absorbing agent by mass percentage; The curing agent is composed of methacryloyloxyethyltrimethylammonium chloride 40%, dimethyldiallylammonium chloride 25%, acrylamide 25% and carboxymethyl cellulose 10% by mass percentage ; The oil absorbing agent is composed of hydrogenated styrene-butadiene-styrene elastomer and high-density polyethylene with a mass ratio of 1:12.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volatile matter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com