A method for treating coal dry distillation wastewater

A technology for waste water treatment and coal dry distillation, which is applied in multi-stage water treatment, water/sewage treatment, water/sewage multi-stage treatment, etc. It can solve the problems of substandard effluent, high treatment difficulty and high treatment cost, and achieve mild operating conditions. , High removal efficiency and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

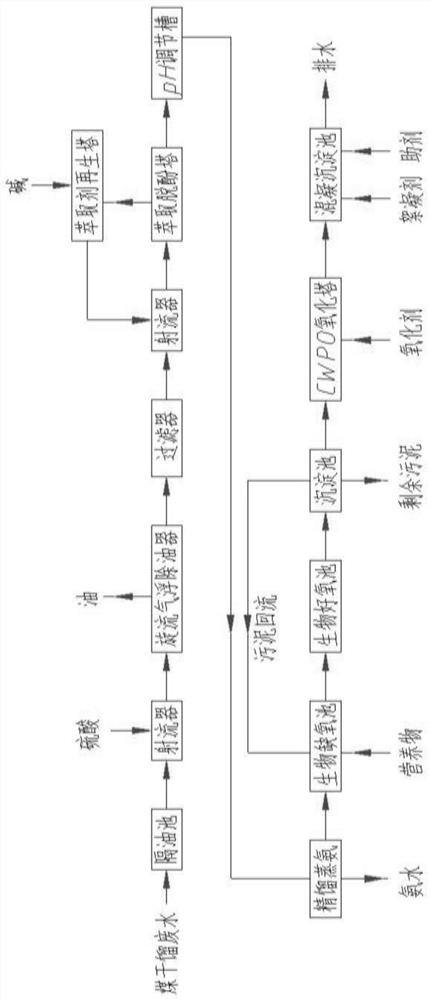

Method used

Image

Examples

Embodiment 1

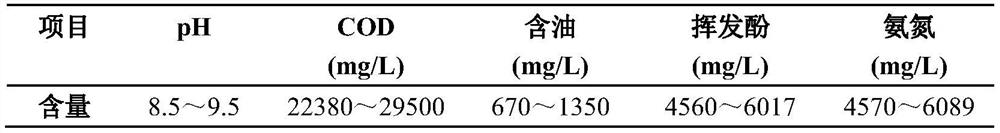

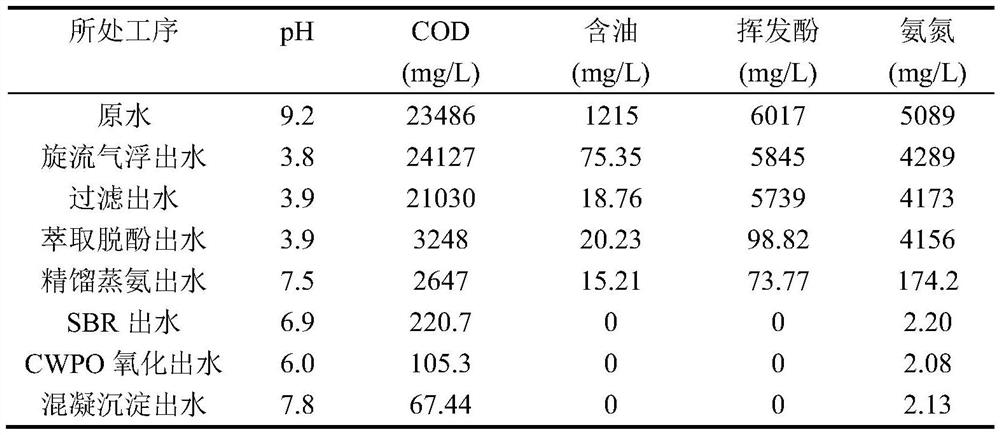

[0031] Coal dry distillation wastewater was treated by oil separation - cyclone air flotation - filtration - extraction and dephenolization - rectification and ammonia distillation - biological anoxic - SBR oxidation - CWPO oxidation - coagulation sedimentation, the treatment capacity is 3L / d, the treatment results are shown in Table 2.

[0032] Table 2 The results of circulating ammonia water treated by combined process

[0033]

[0034] As can be seen from Table 2, the oil content in the effluent of cyclone air flotation dropped from 1215mg / L to 75.35mg / L, and the removal rate reached 93.8%; 98.3%; the ammonia nitrogen in the effluent of rectification and distilled ammonia dropped from 4156 to 174.2mg / L, and the removal rate reached 95.8%. COD, oil, volatile phenol and ammonia nitrogen in coagulation and sedimentation water meet the direct discharge standard of GB16171-2012 in the Discharge Standard of Pollutants for Coking Chemical Industry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com