Anti-blocking compound fertilizer and preparation method thereof

A compound fertilizer and anti-caking technology, which is applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problem of wasting useful resources, etc., and achieve the effect of reducing processing costs, good anti-caking application effect, and enriching nutrient elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

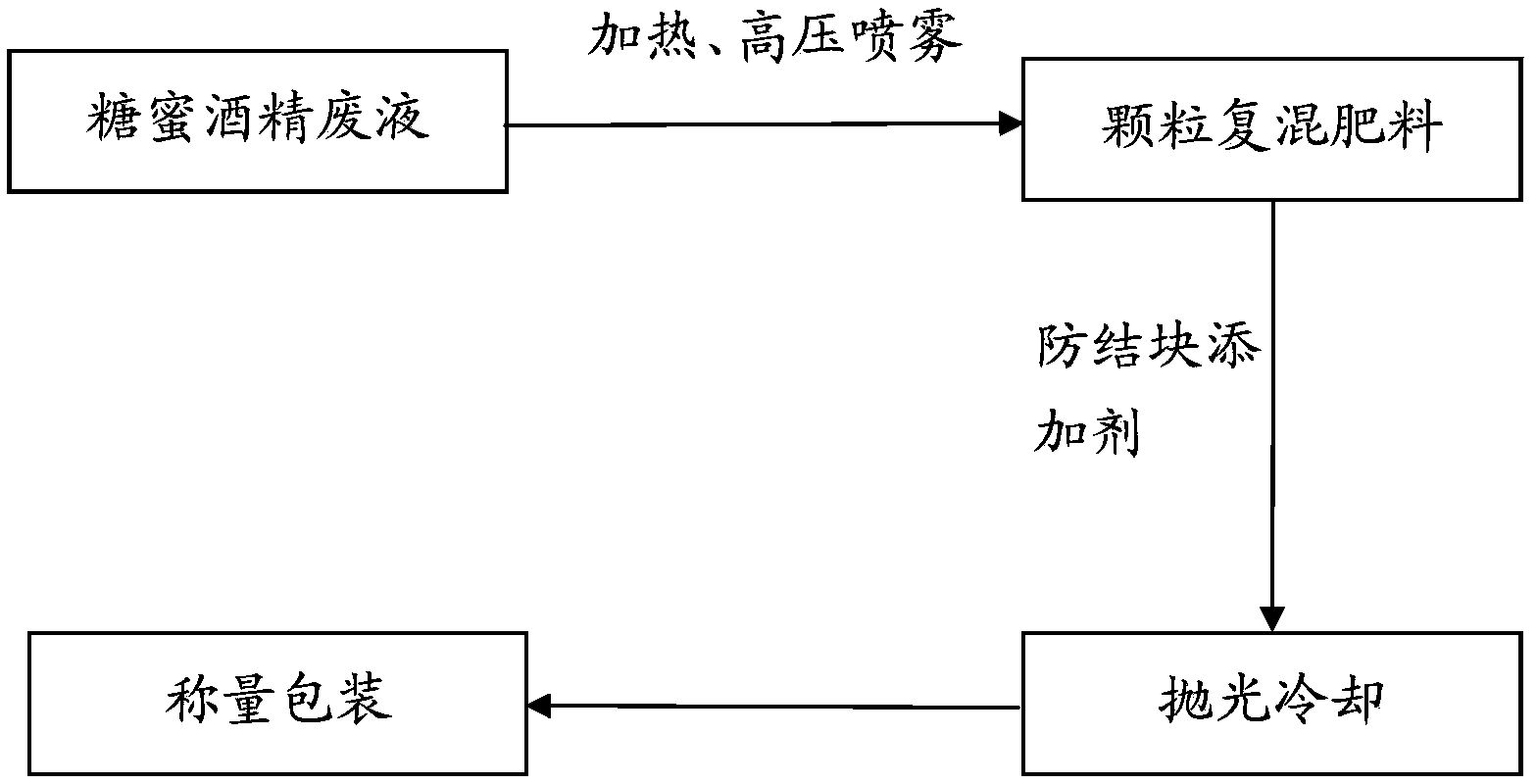

Method used

Image

Examples

Embodiment 1

[0036] Heat the alcohol-concentrated waste liquid containing 45% of the total solids to 60°C, spray it with a high-pressure spray gun, so that the compound fertilizer is fully covered by the misty coating agent-molasses alcohol waste liquid before entering the coating cylinder, and then follow the Add anti-caking additives (purchased from powdered anti-caking materials produced by Guangdong New Lvyuan Chemical Co., Ltd.) to 1.5% of the total amount of granular fertilizers to allow them to fully adhere to the surface of fertilizer particles in the rotary coating drum, and the granular fertilizers are then After cylindrical polishing and cooling, the coating anti-knot treatment is completed.

Embodiment 2

[0038] Heat the concentrated alcohol waste liquid containing 65% of the total solids to 80°C, and spray it with a high-pressure nozzle, so that the compound fertilizer is fully covered by the misty coating agent-molasses alcohol waste liquid before entering the coating cylinder, so that it Fully adhere to the surface of the fertilizer granules in the rotary coating cylinder, and the granular fertilizer is polished and cooled by the cylinder to complete the coating and anti-knot treatment.

Embodiment 3

[0040]Heat the alcohol concentrated waste liquid containing 55% of the total solids to 70°C, spray it with a high-pressure nozzle, so that the compound fertilizer is fully covered by the misty coating agent-molasses alcohol waste liquid before entering the coating cylinder, and then follow the 0.5% of the total amount of granular fertilizer is added with anti-caking additive talc powder to allow it to fully adhere to the surface of fertilizer particles in the rotary coating cylinder. After the granular fertilizer is polished and cooled by the cylinder, the anti-caking treatment of coating is completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com