Regenerating method for aqueous film-forming foam fire extinguishing agent

A foam fire extinguishing agent and water film-forming technology, which is applied in fire protection equipment and other directions, can solve the problems of difficult regeneration of water film-forming foam fire extinguishing agent, and achieve the effects of low cost, good technical effect and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 700kg of 6% type IA grade aqueous film-forming foam fire extinguishing agent to 1m 3 In a jacketed reactor, heated to 70°C. Under stirring, add 50 kg of n-hexane and 150 kg of ethyl acetate in turn; speed up the stirring speed, observe the liquid level, the stirring speed can make the two phases mix without producing foam; Mutually. The upper layer is an organic phase, and the lower water phase is a foam fire extinguishing agent.

[0026] Several organic phases were combined and distilled, and fractions at 69°C (the boiling point of n-hexane) and 77°C (the boiling point of ethyl acetate) were collected respectively.

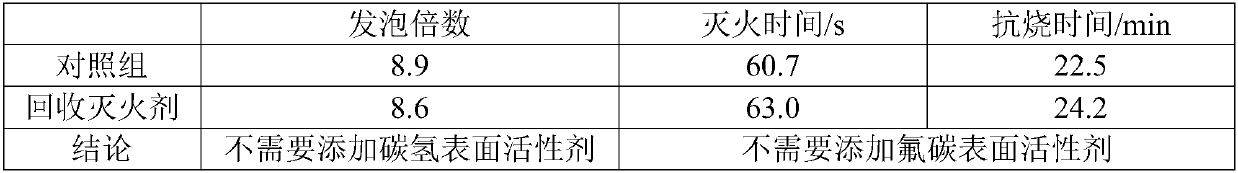

[0027] The lower aqueous phase was prepared with a foam solution at a ratio of 6:94. In the foam performance testing device, the foaming ratio, fire extinguishing time, and burning time of the fire extinguishing agent were measured, as shown in Table 1.

[0028] Table 1 Performance of 6% type recovered foam fire extinguishing agent

[0029]

[0...

Embodiment 2

[0032] Add 700kg of 3% type IA grade aqueous film-forming foam fire extinguishing agent to 1m 3 In a jacketed reactor, heated to 65°C. Under slow stirring, add 150kg of n-hexane and 200kg of ethyl acetate in turn; speed up the stirring speed, observe the liquid level, the stirring speed can make the two phases mix without foaming; after stirring for 45 minutes, let stand for 15 minutes, separate layers, and heat The two phases were separated.

[0033] The treatment of the upper organic phase is the same as in Example 1.

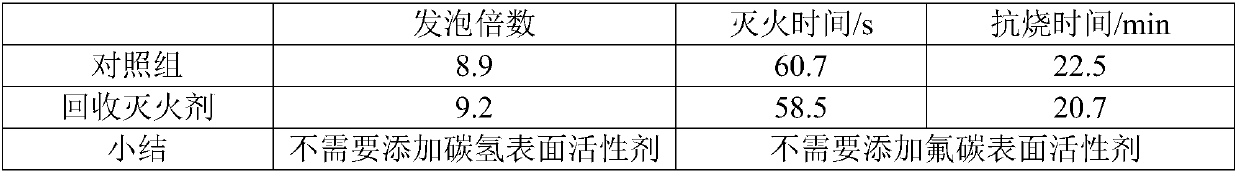

[0034] The lower aqueous phase is foam fire extinguishing agent. Prepare a foam solution at a ratio of 3:97, and measure the foaming ratio, fire extinguishing time, and anti-burning time of the fire extinguishing agent in the foam performance testing device, see Table 2.

[0035] Table 2 Performance of 3% type recovered foam fire extinguishing agent

[0036]

[0037] It can be seen from Table 2 that the performance of the aqueous film-forming foam fire...

Embodiment 3

[0039] Add 700kg of 3% type IC grade aqueous film-forming foam fire extinguishing agent to 1m 3 In a jacketed reactor, heated to 85°C. Under slow stirring, add 108.5kg of toluene successively; speed up the stirring speed, observe the liquid level, the stirring speed can make the two phases mix without foaming; after stirring for 30 minutes, let stand for 15 minutes, separate layers, and separate the two phases while hot. We also found an interesting phenomenon: during the cooling process, it separated into two phases, and the upper organic phase accounted for the majority in volume. The ratio of the aqueous phase to the organic phase changed from 6.5:1 to 0.81:1 before and after heating and extraction. In other words, toluene not only extracts organic matter, but also extracts certain water or water-soluble substances. This is because the solvents such as ethylene glycol and glycol ether in the foam fire extinguishing agent are soluble in hot toluene and water, and together w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com