Biological filler and mounting structure and method thereof

A technology of biological filler and installation method, which is applied in the field of water treatment, can solve the problems of difficult to realize large-scale mechanized production, inconvenient transportation, high investment cost, etc., so as to increase the speed and the amount of biological attachment, save the amount of materials used, and improve the treatment efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

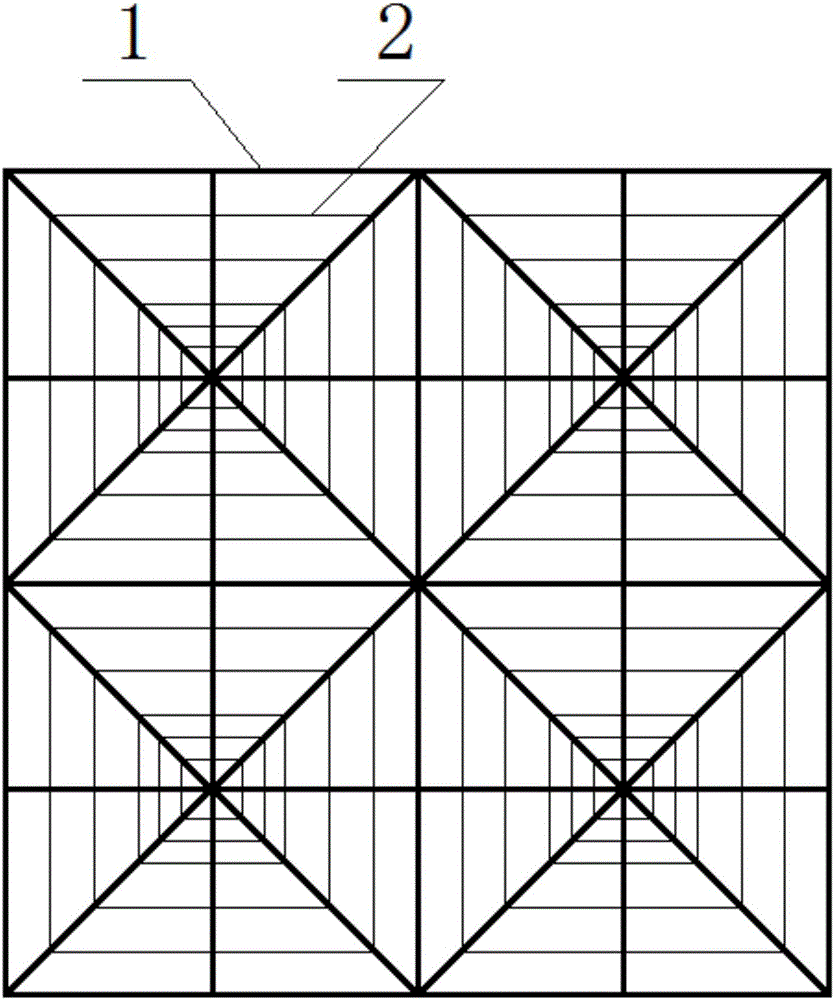

[0055] Such as figure 1 As shown, the present embodiment provides a kind of biofiller, comprising:

[0056] A number of film-hanging units are arranged in a matrix between several film-hanging units;

[0057] Each film-hanging unit includes several skeletons 1 and film-hanging meshes 2, the several skeletons 1 intersect to form the center of each film-hanging unit, and the film-hanging meshes 2 are distributed from dense to sparse from the center to the surrounding On the skeleton 1, each hanging film unit forms a spider web structure.

[0058] The film-hanging meshes 2 of the film-hanging unit in this embodiment are arranged in a multi-circle regular quadrilateral arrangement.

[0059] The skeleton 1 in this embodiment is made of nylon material; the film-hanging mesh 2 is made of vinylon material with good hydrophilicity.

[0060] The biofiller in this example is made into a filler with a planar two-dimensional structure using conventional textile machinery.

Embodiment 2

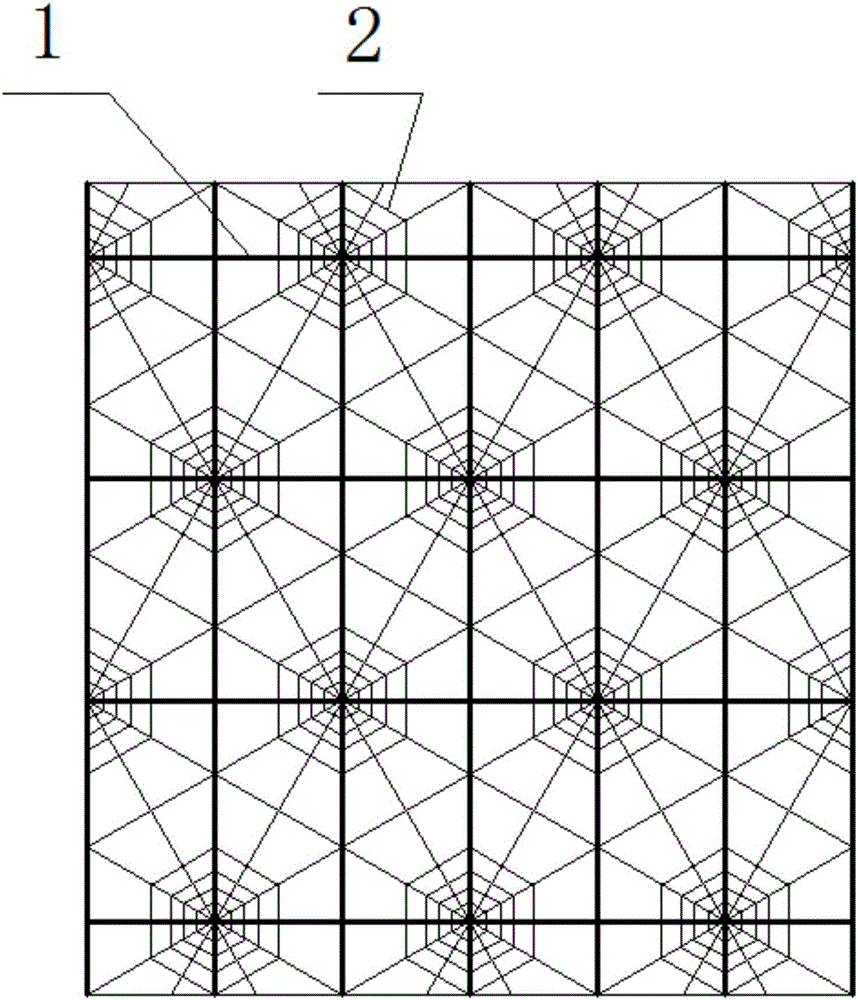

[0062] Such as figure 2 As shown, the difference between the biological filler provided in this embodiment and that of Example 1 is:

[0063] The film-hanging meshes 2 of the film-hanging unit in this embodiment are arranged in a multi-circle regular hexagonal arrangement.

[0064] Skeleton 1 adopts polyester material.

Embodiment 3

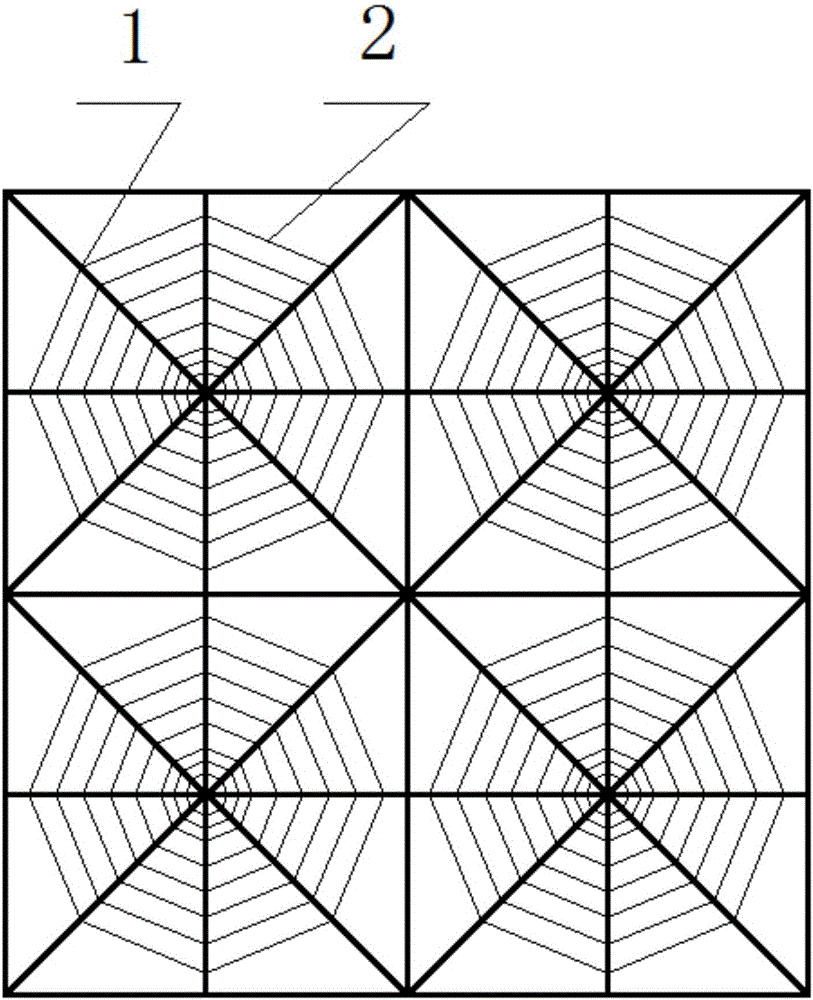

[0066] Such as image 3 As shown, the difference between the biological filler provided in this embodiment and that of Example 1 is:

[0067] The film-hanging meshes 2 of the film-hanging unit in this embodiment are arranged in a multi-circle regular octagonal arrangement.

[0068] Skeleton 1 adopts polyester material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com