Sludge drying incineration system based on thermal power plant

A technology for sludge drying and thermal power plants, which is applied in oxidation treatment of sludge, dehydration/drying/concentrated sludge treatment, incinerators, etc. It can solve the problems of not meeting the moisture content requirements of sludge incineration and high cost, and achieve energy saving. Steam treatment investment, small initial investment, great operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

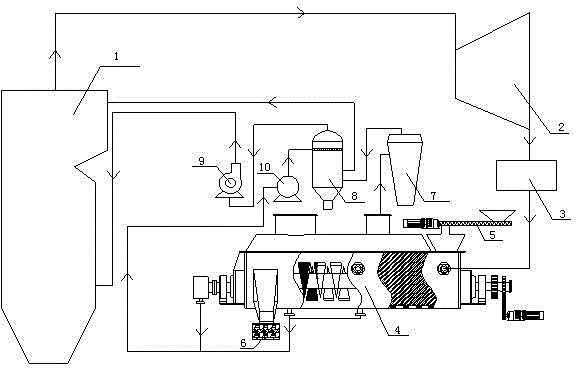

[0036] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

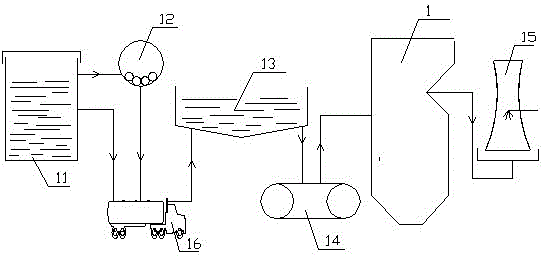

[0037] see figure 1 , is an embodiment of the sludge drying and incineration system relying on a thermal power plant of the present invention. The thermal power plant includes a start-up boiler and a power plant boiler 1. The superheated steam generated by the power plant boiler 1 is connected to the steam turbine 2, the auxiliary steam pipeline of the start-up boiler and a steam connection in sequence through pipelines. Box 3, (starting boiler auxiliary steam pipeline is not drawn).

[0038] The system includes a paddle-type sludge dryer 4, an auger-type feeder for feeding it, and a finished sludge collection device 6 for collecting its finished sludge.

[0039]Paddle type sludge dryer 4 is a model with no direct contact between steam and sludge, and the moisture content of dried sludge after drying is about 50%. There are steam inlet, exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com