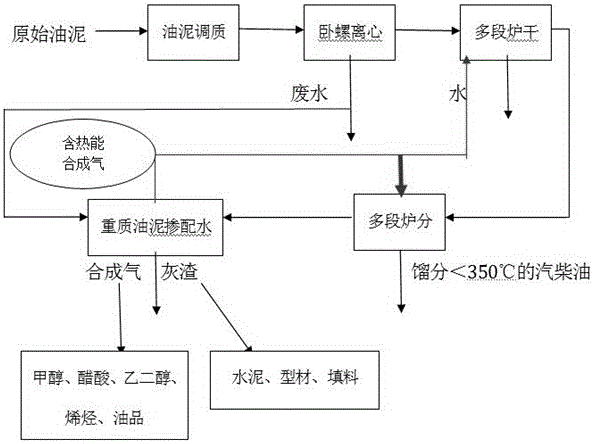

Oil-sludge separation and gasification recycling method

A technology for resource utilization and sludge, which is applied in chemical instruments and methods, granular/powder fuel gasification, chemical industry, etc., can solve the problem of high-colloid heavy oil pollution in sludge and can not be harmless, and reduce the moisture content of sludge. and follow-up treatment pressure, difficulties in large-scale industrialization, etc., to achieve the effects of excellent industrial application economy, significant resource integration benefits, and excellent economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Taking the oily sludge at the bottom of a crude oil settling tank of a joint station of an oil production plant in northern Shaanxi as an example, its initial water content is 40%, and it contains 35% organic matter (of which gasoline and diesel components with a boiling point below 350°C account for 12%, and heavy oil components Accounting for 13%), the mud content is 25%, the specific treatment method is as follows:

[0034]The oil sludge after chemical conditioning, centrifugal dehydration and reduction treatment is used as the material for oil sludge separation-gasification treatment; the material is sent to the upper hopper of the multi-stage furnace of the integrated reactor for drying and quality separation, and passed through the feeding The screw machine and material pipe enter the drying section of the multi-stage furnace. Under the action of the thrust of the rake teeth in the furnace and the rotation of the rake arm, the material evenly turns over and moves c...

Embodiment 2

[0041] Taking the oil sludge from an oil production plant in northern Shaanxi as an example, its initial water content is 20%, and it contains 55% organic matter (of which gasoline and diesel components with a boiling point below 350°C account for 21%, and heavy oil components account for 23%). 25%, the specific treatment method is as follows:

[0042] The oil sludge after chemical conditioning, centrifugal dehydration and reduction treatment is used as the material for oil sludge separation-gasification treatment; the material is sent to the upper hopper of the multi-stage furnace of the integrated reactor for drying and quality separation, and passed through the feeding The screw machine and material pipe enter the drying section of the multi-stage furnace. Under the action of the thrust of the rake teeth in the furnace and the rotation of the rake arm, the material evenly turns over and moves centripetally and centrifugally on the surface of the metal furnace layer with heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com