Non-stratified oil pit harmless treatment method and oil sludge fuel block prepared thereby

A harmless treatment, non-layered technology, applied in chemical instruments and methods, fixed/solidified sludge treatment, fuel, etc., can solve the problem of non-hazardous treatment and resource utilization of oil sludge, investment in oily sludge pit treatment Large, high content of toxic and harmful substances, etc., to achieve good effect of oil sludge fuelization, improve availability, and improve the quality of resource-based products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

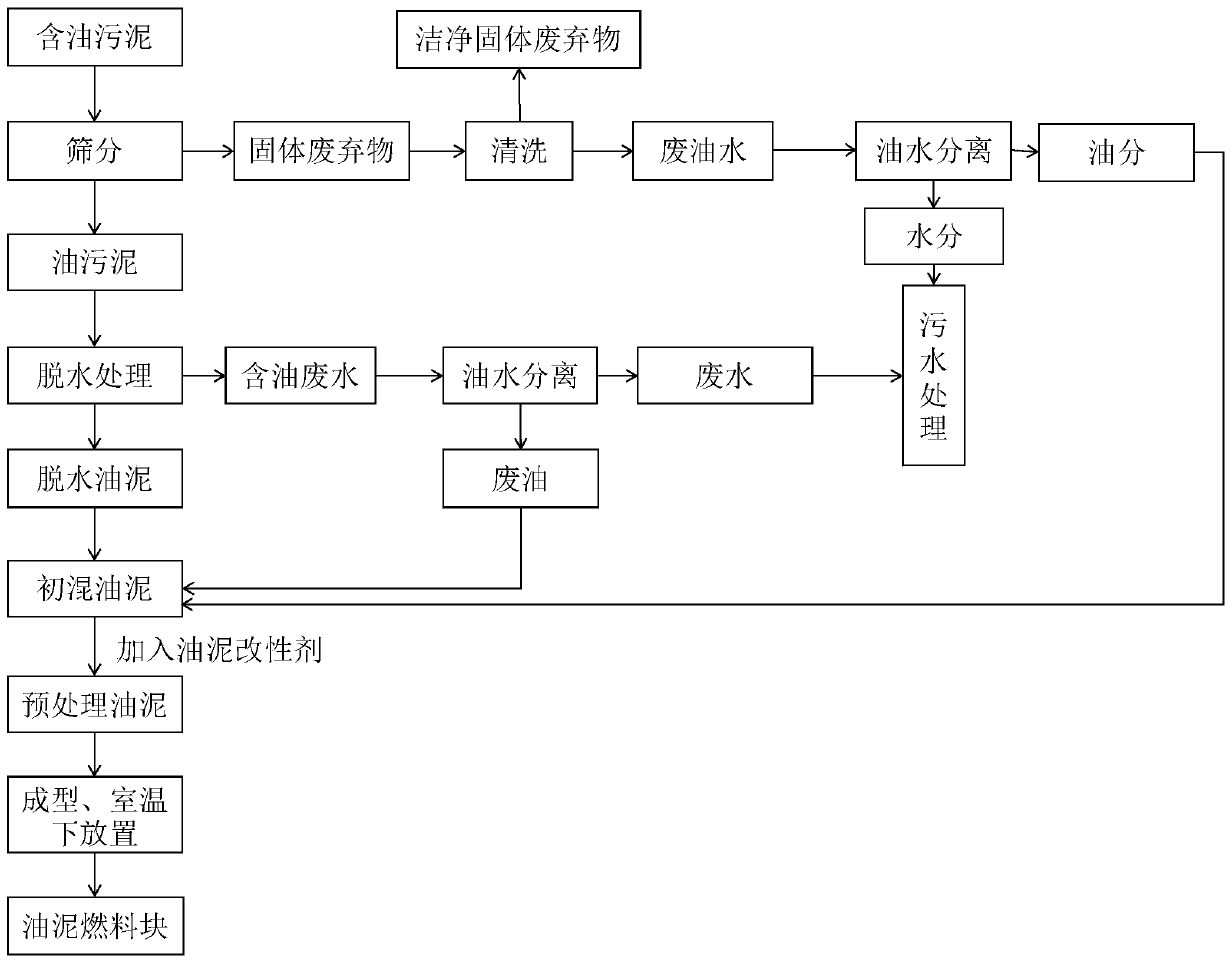

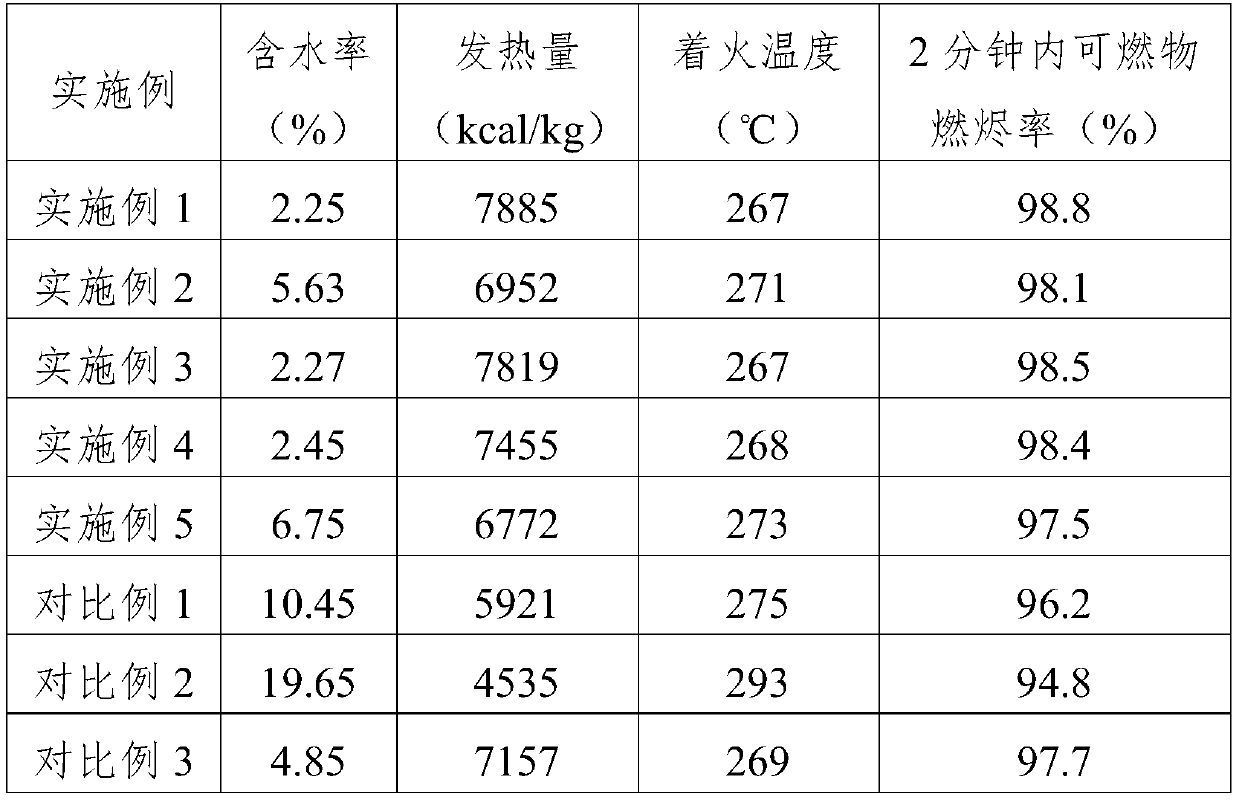

[0064] ①Sieving the oily sludge in the non-layered oil pit to remove solid waste to obtain oily sludge; dehydrating the obtained oily sludge to obtain oily wastewater and dewatered oily sludge with a moisture content of 15%, and then The obtained oil-containing wastewater is subjected to oil-water separation to obtain waste oil and wastewater, and the obtained wastewater is subjected to sewage treatment.

[0065] ② Mix the dewatered oil sludge and the waste oil in step ① uniformly to obtain a primary mixed sludge with an oil content of 40%, then add a sludge modifier to the primary mixed sludge and mix uniformly to obtain a pretreated sludge ; Wherein, the mass ratio of the primary mixed sludge and the sludge modifier is 100:20; the sludge modifier is composed of auxiliary material (straw) 66.5% in mass percentage, curing agent 16.5%, calcium oxide 6 %, bentonite 9% and cement 2%; the curing agent consists of methacryloyloxyethyltrimethylammonium chloride 40%, dimethyl diallyl...

Embodiment 2

[0069] Embodiment 2 is basically the same as Embodiment 1, the difference is:

[0070] In step ②, the oil sludge modifier is composed of 50% of auxiliary material (stalk) in mass percentage, 27% of curing agent, 6% of calcium oxide, 12% of bentonite and 5% of cement; In percentage terms, it is composed of 35% methacryloyloxyethyl trimethyl ammonium chloride, 25% dimethyl diallyl ammonium chloride, 25% acrylamide and 15% carboxymethyl cellulose.

Embodiment 3

[0072] Embodiment 3 is basically the same as Embodiment 1, the difference is:

[0073] In step ②, the oil sludge modifier is composed of 66.5% of auxiliary materials (straw) in mass percentage, 16.5% of curing agent, 6% of calcium oxide, 8.5% of bentonite, 2% of cement and 0.5% of oil absorbing agent; The curing agent consists of 40% methacryloxyethyltrimethylammonium chloride, 25% dimethyl diallyl ammonium chloride, 25% acrylamide and 10% carboxymethyl cellulose in mass percent ; The oil-absorbing agent is composed of hydrogenated styrene-butadiene-styrene elastomer and high-density polyethylene with a mass ratio of 1:12.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com