Cleaning and blockage relieving technology of gathering and transportation system for oil and natural gas field highly containing sulfuric acid

A technology for sour natural gas, gathering and transportation system, which is applied in the field of blocking removal technology and gathering and transportation system of high-sulfuric oil and natural gas fields, can solve problems such as no blocking removal technology for gas gathering and transportation system in natural gas fields, and achieves the effect of not polluting the environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] For well 303-3 in a certain gas field with blockage, stop natural gas transmission, close the wellhead air intake control valve, drain the gas in the gathering and transportation system, and purge the system pipeline with pure natural gas to vent.

[0079] Dissolve 10 tons of FeS passivator sodium nitrite and 8 tons of hydrogen sulfide inhibitor N-methyldiethanolamine in 80m 3 Water, pumped into the system and circulated for cooking for 4 hours to achieve the purpose of deodorization and passivation.

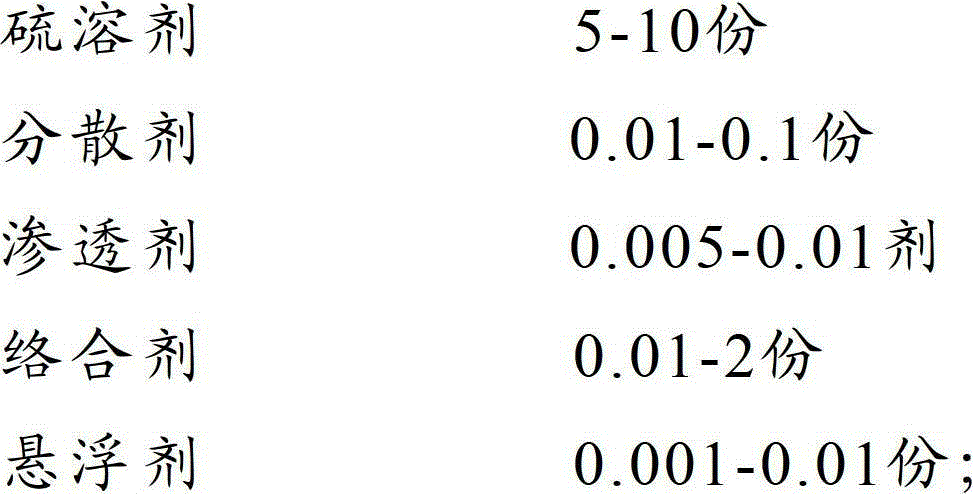

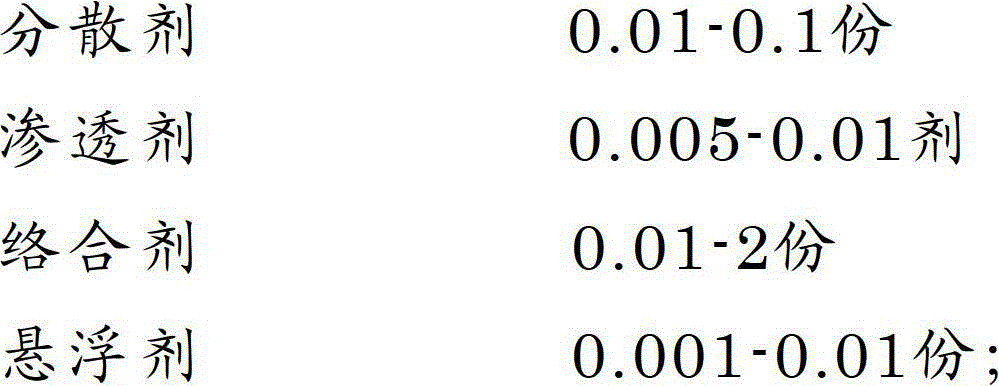

[0080] Warm the following prepared cleaning agent aqueous solution to 90°C and soak in the system for 4 hours. In the sulfur-dissolved cleaning agent aqueous solution, the active ingredients and their concentrations are respectively:

[0081]

[0082] Then heat the prepared cleaning agent aqueous solution to 90°C by steam, pressurize it through a high-pressure water jet pump, use a high-pressure hose to transport it to the cleaning nozzle, and use the high-pressure cle...

Embodiment 2

[0086] For well 303-3 in a certain gas field that is clogged, in the case of non-stop production, the clogged throttle valve is surrounded by an arc sensor, and then the high-frequency heating host is connected, and the temperature in the valve is 5 minutes. 70-80°C, the temperature difference between the inside and outside of the valve is 3°C-10°C, after heating for 3 minutes, the clogged valve will resume normal operation and realize unblocking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com