Special bubbling system for dust removal by wet flue gas desulfurization

A technology for wet desulfurization and flue gas, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as difficult removal, difficulty in charging, and insufficient absorption of flue gas. Simple maintenance and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

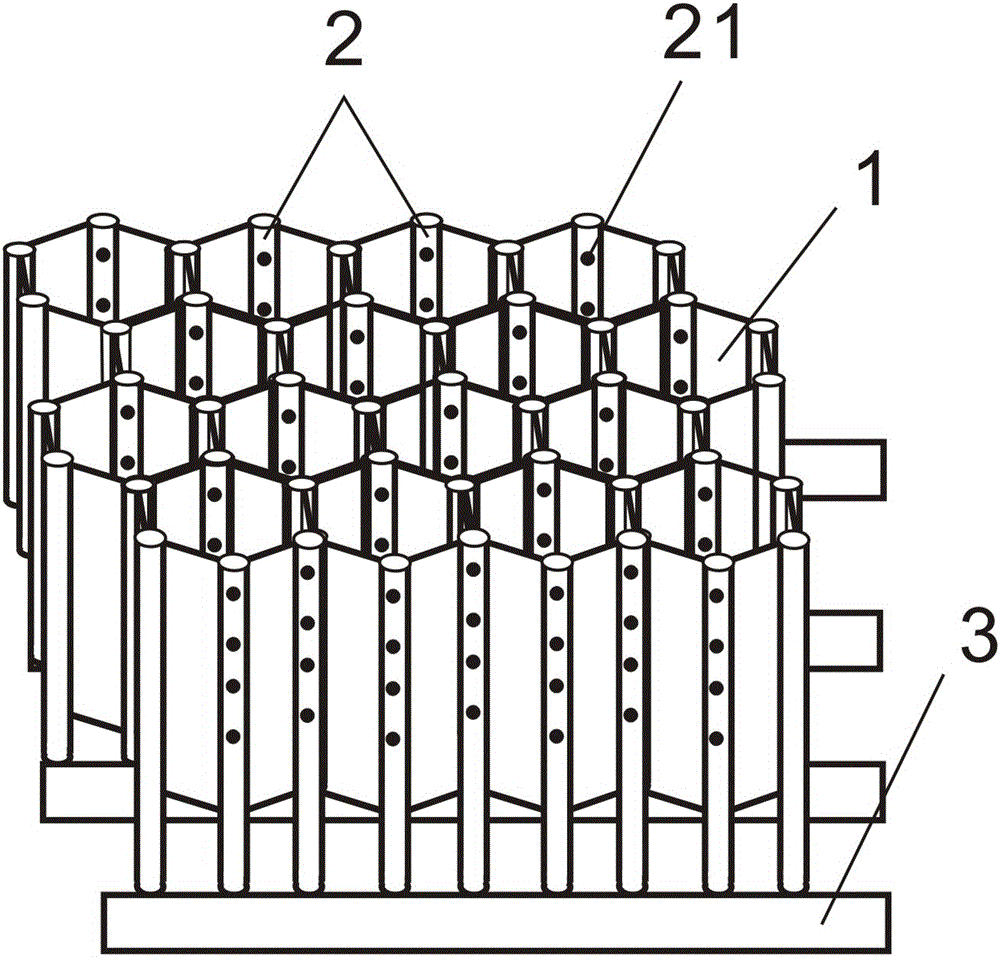

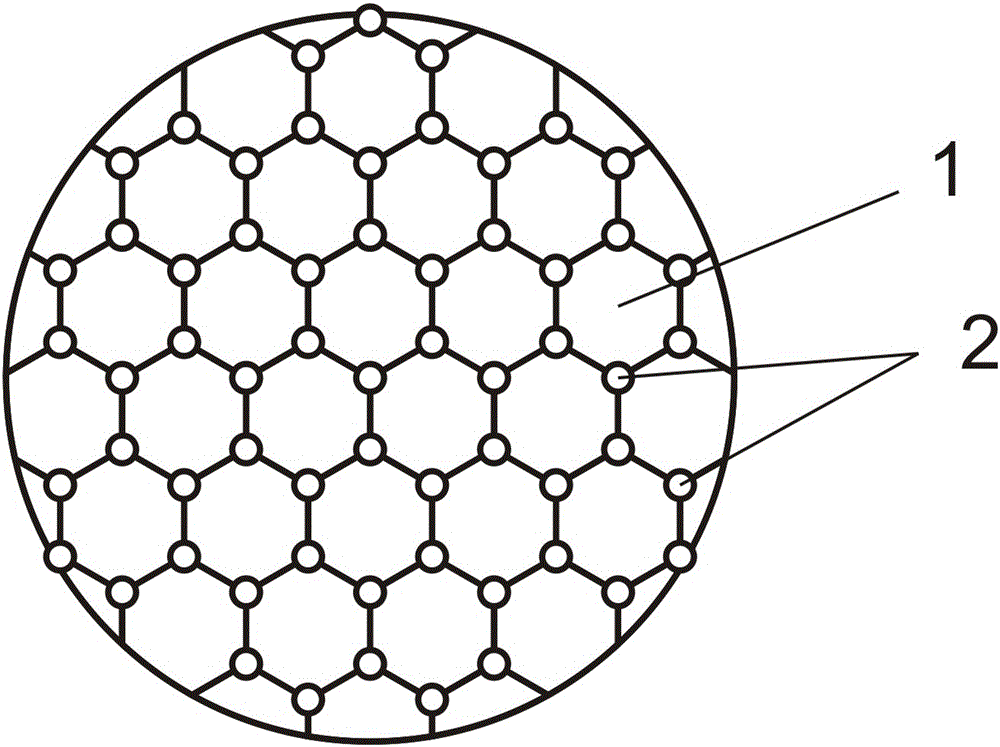

[0024] like figure 1 , figure 2 and image 3 As shown, a special bubbling system for flue gas wet desulfurization and dust removal, including a number of hexagonal flue gas pipes 1, bubbling pipes 2 on the side walls of the flue gas pipe 1, and a delivery subsystem 3 for absorbing wetting liquid, The bubbling tube has small holes 21 for blowing liquid bubbles into the flue gas tube 1 , and the lower or upper end of the bubbling tube 2 is connected with the absorbing wetting liquid delivery subsystem 3 .

[0025] The flue gas pipe 1 in this embodiment is hexagonal, and a plurality of flue gas pipes 1 can form a seamless splicing, and the bubbling pipe 2 is just located at the splicing corner of the three flue gas pipes 1 . The size and number of flue gas pipes 1 are configured according to the size of the desulfurization and dust removal tower and actual flue gas working conditions. The diameter of the inscribed circle of the section of the flue gas pipe 1 in this embodimen...

Embodiment 2

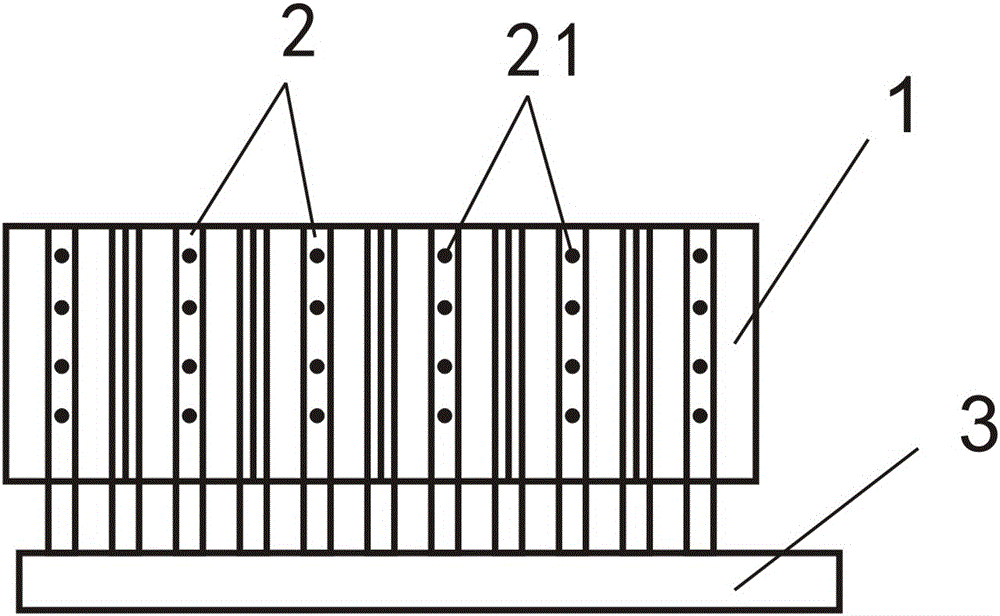

[0029] like Figure 4 As shown, another special bubbling system for flue gas wet desulfurization and dust removal. The special bubbling system for flue gas wet desulfurization and dust removal in this embodiment is basically the same as the overall system in Embodiment 1, the differences are: 1. The flue gas pipe 1 in this embodiment is quadrilateral, and multiple flue gas pipes 1 form a seamless splicing 1. The bubbling tube 2 is located at the center of the side wall of each flue gas tube 1; 2. Each bubbling tube 2 is provided with 8 liquid vapor bubble releasing devices 21 in the form of bubbling nozzles. The size and number of flue gas pipes 1 are configured according to the size of the desulfurization and dust removal tower and actual flue gas working conditions. The diameter of the inscribed circle of the section of the flue gas pipe 1 in this embodiment is 80 mm.

Embodiment 3

[0031] like Figure 5 As shown, another special bubbling system for flue gas wet desulfurization and dust removal. The special bubbling system for flue gas wet desulfurization and dust removal in this embodiment is basically the same as the overall system in embodiment 1, the difference is that only three bubbling pipes 2 are set on each hexagonal flue gas pipe 1 in this embodiment . In the case that the absorption and wetting efficiency can be achieved, the production efficiency of the product can be improved and the cost of the product can be reduced. The size and number of flue gas pipes 1 are configured according to the size of the desulfurization and dust removal tower and actual flue gas working conditions. The diameter of the inscribed circle of the section of the flue gas pipe 1 in this embodiment can be set to 80 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com