Seed precipitation decomposition process for high-content total organic carbon in low-temperature Bayer process

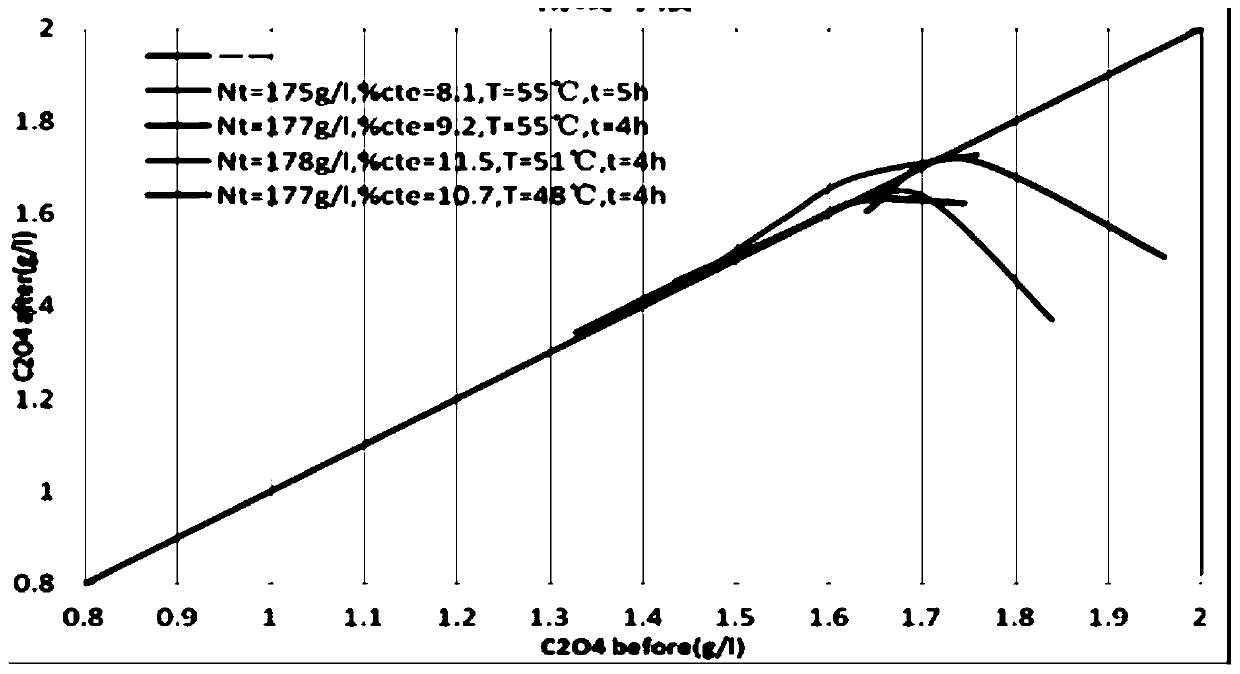

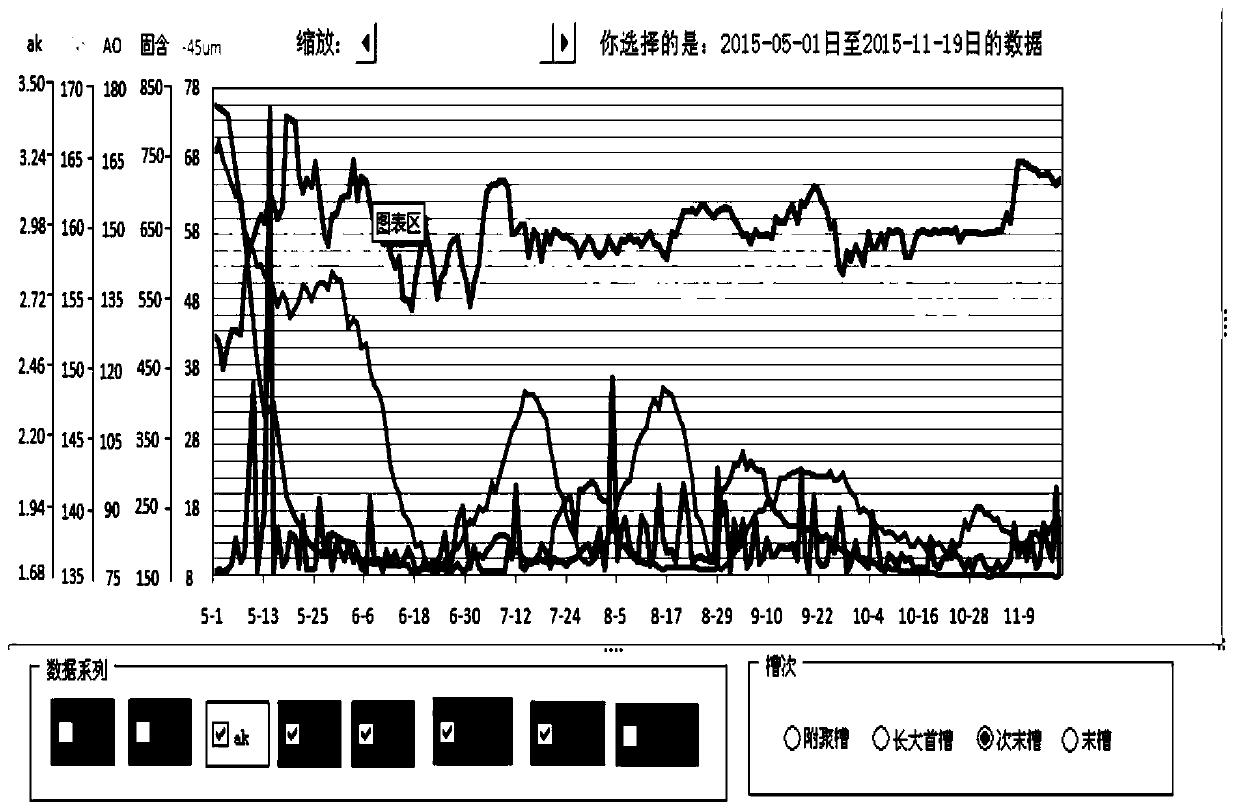

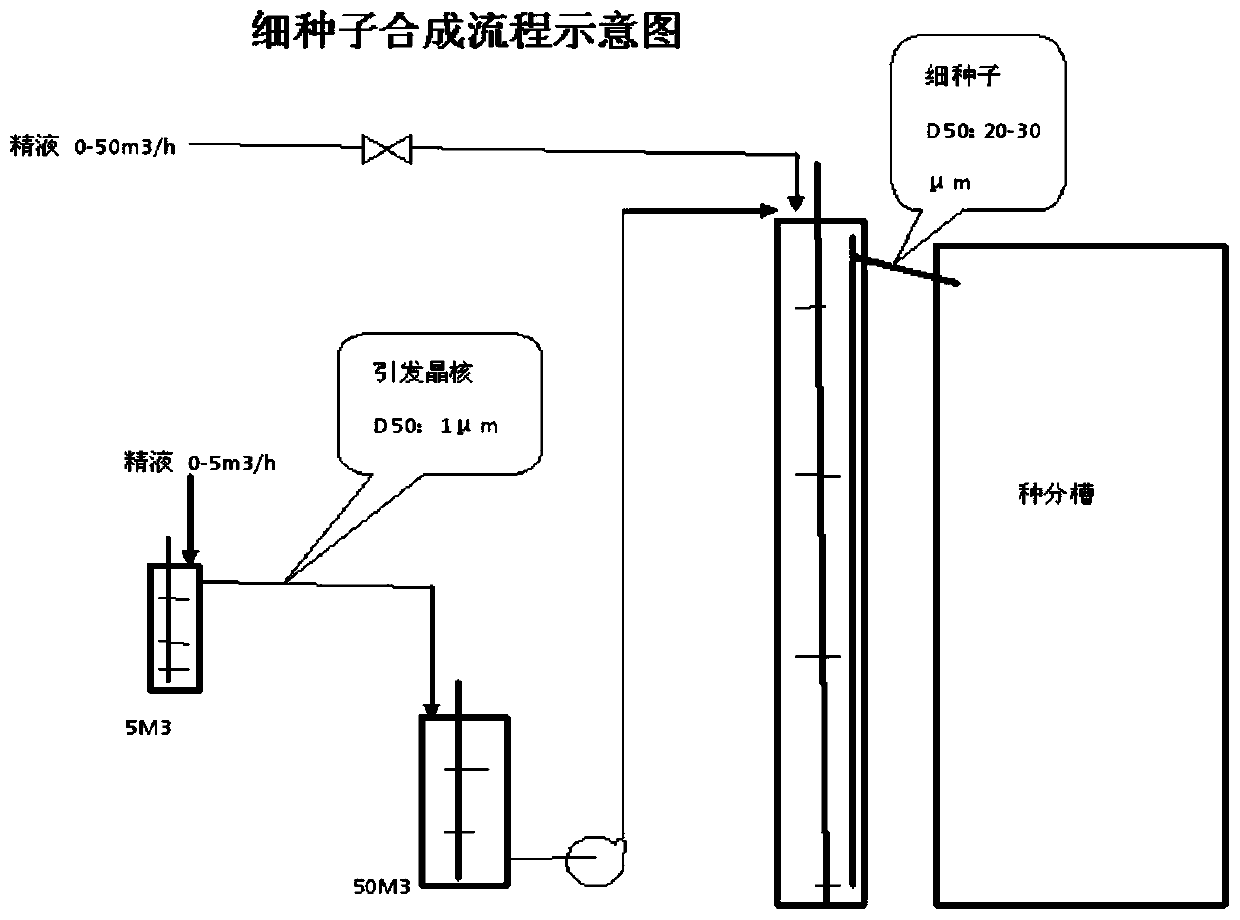

A technology of total organic carbon and Bayer method, which is applied in the field of low-temperature Bayer method and high total organic carbon seed decomposition technology, which can solve the problems of affecting decomposition rate and seed crystal agglomeration, difficult washing of flat plate filter, and scabbing of decomposition tank , to achieve the effect of helping to control the decomposition granularity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] The low-temperature Bayer method high total organic carbon species decomposition process provided in this example is a one-stage decomposition process, and the ore origin is India, including the following steps:

[0059] Step 1: Add oxalate seed crystals to the circulating mother liquor to control the solid content to 65g / L, and adjust the temperature of the circulating mother liquor to 51°C to precipitate oxalate in the circulating mother liquor to obtain a low oxalate mother liquor.

[0060] Step 2: Adjust the concentration of caustic soda in the circulating mother liquor to 199g / L, and mix the adjusted circulating mother liquor with the above-mentioned Australian ore to obtain a batching ore, and perform bauxite dissolution, red mud separation and washing on the batching ore , to obtain sodium aluminate solution;

[0061] Step 3: reducing the oxalate concentration in the sodium aluminate solution to obtain a low oxalate sodium aluminate solution;

[0062] Step 4: ad...

Embodiment 2

[0069] The low-temperature Bayer method high total organic carbon species decomposition process provided in this example is a one-stage decomposition process, and the origin of the ore is Brazil, including the following steps:

[0070] Step 1: Add oxalate seed crystals to the circulating mother liquor, control the solid content to 50g / L, and adjust the temperature of the circulating mother liquor to 50-52°C to precipitate oxalate in the circulating mother liquor to obtain a low oxalate mother liquor.

[0071] Step 2: Adjust the caustic alkali concentration in the circulating mother liquor to 198g / L, mix the adjusted circulating mother liquor with the above-mentioned Australian ore to obtain a batching ore, and perform bauxite dissolution, red mud separation and washing on the batching ore , to obtain sodium aluminate solution;

[0072] Step 3: reducing the oxalate concentration in the sodium aluminate solution to obtain a low oxalate sodium aluminate solution;

[0073] Step 4...

Embodiment 3

[0080] The low-temperature Bayer method high total organic carbon species decomposition process provided in this example is a one-stage decomposition process, and the ore origin is Malaysia, including the following steps:

[0081] Step 1: Add oxalate seed crystals to the circulating mother liquor to control the solid content to 80g / L, and adjust the temperature of the circulating mother liquor to 50-52°C to precipitate oxalate in the circulating mother liquor to obtain a low oxalate mother liquor.

[0082] Step 2: Adjust the concentration of caustic soda in the circulating mother liquor to 200g / L, and mix the adjusted circulating mother liquor with the above-mentioned Australian ore to obtain a batching ore, and perform bauxite dissolution, red mud separation and washing on the batching ore , to obtain sodium aluminate solution;

[0083] Step 3: reducing the oxalate concentration in the sodium aluminate solution to obtain a low oxalate sodium aluminate solution;

[0084] Step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com