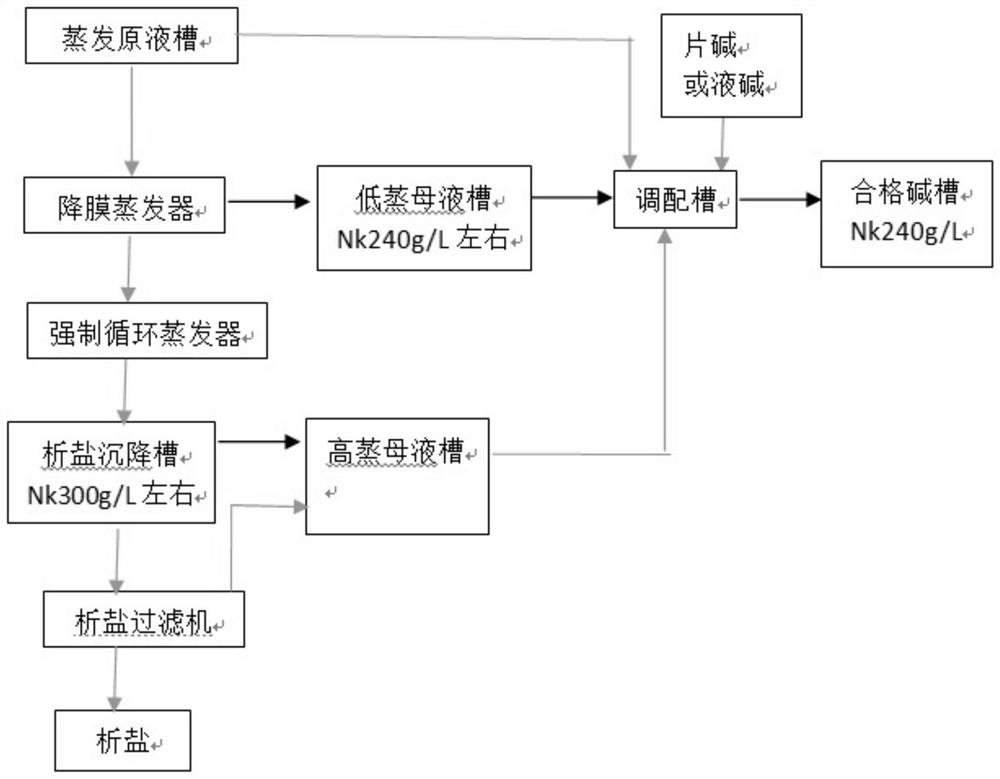

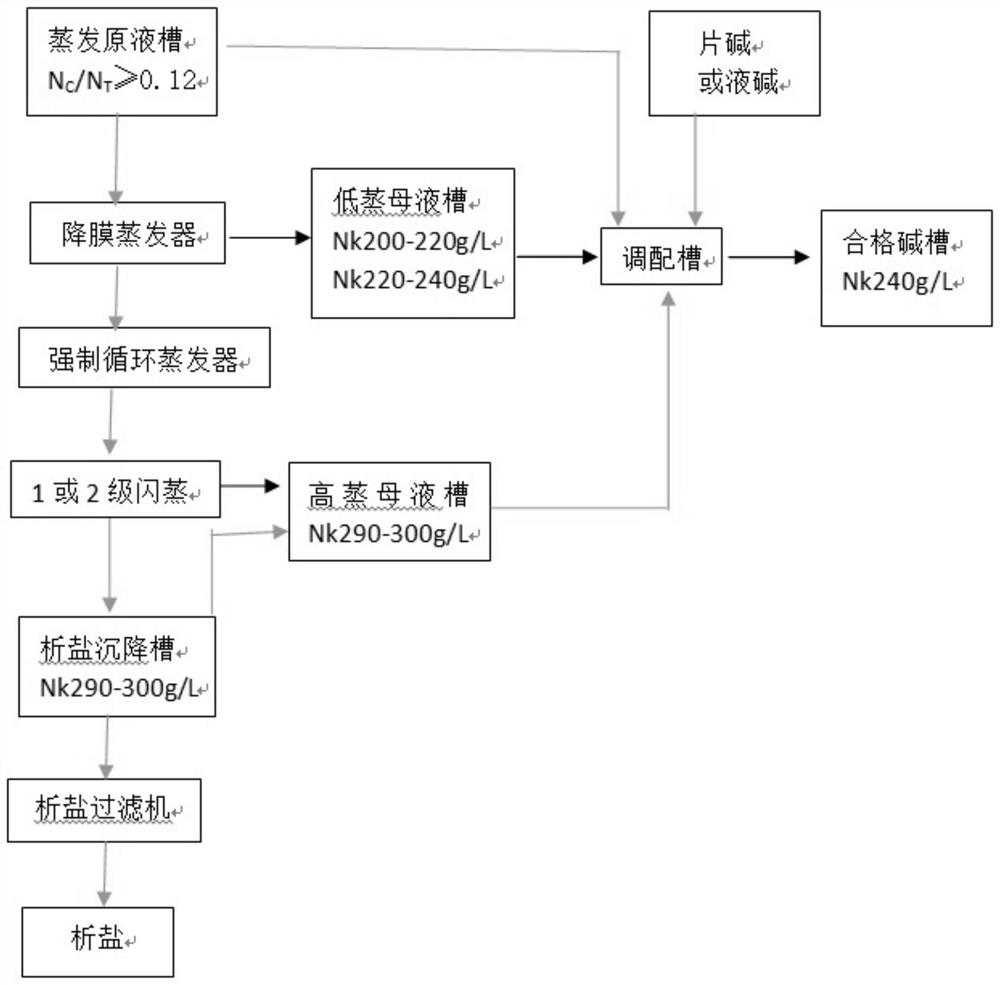

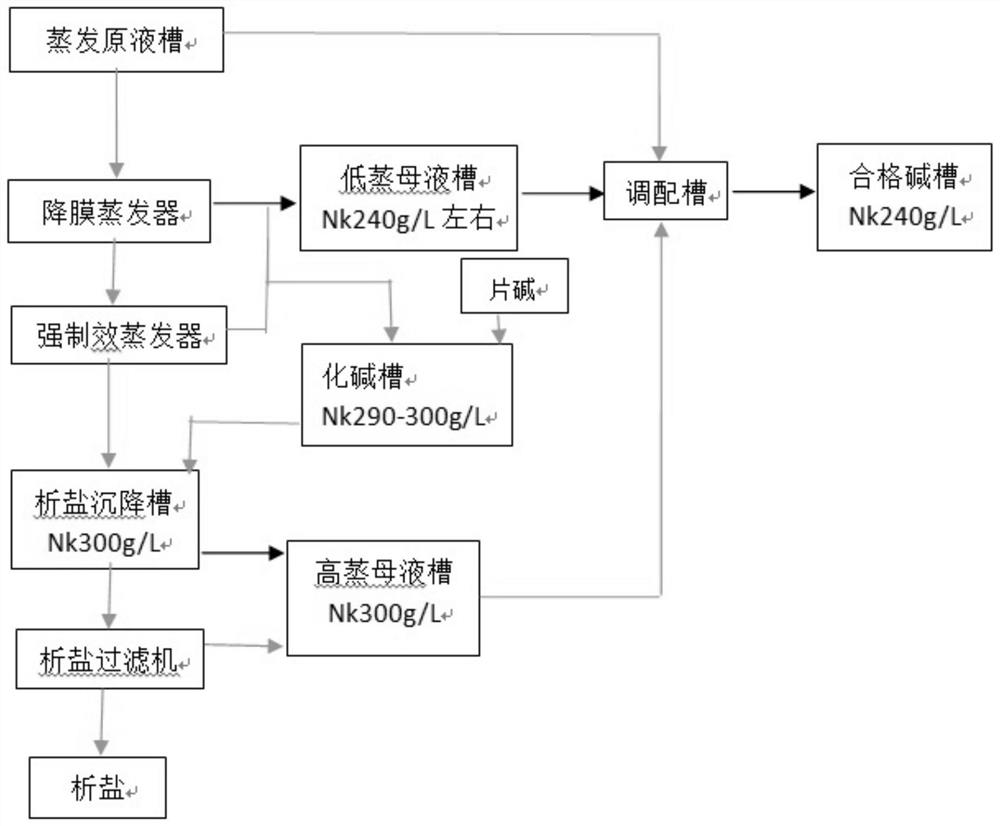

A method for improving the Bayer process high-carbon alkali solution evaporation and salt precipitation process

A process improvement, alkaline solution technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of high evaporation steam consumption, high carbon and alkali in the system, difficult salt precipitation, etc., and achieve the improvement of product particle size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Example 1. Evaporating the N of the stock solution K The concentration is 160g / L, N C / N T is 0.15, and the discharge concentration of the falling film evaporator is controlled at N K 200g / L, forced discharge N K At 270g / L, two flashes are used for salt discharge operation, the forced discharge temperature is 105°C, once flashed to 95°C, flashed again to 90°C, flashed to N K The concentration is 295g / L. Final output N C / N T Dropped to 0.06, the washing cycle of the falling film evaporator is 20 days, and the washing cycle of the forced circulation evaporator is 5 days. After one month of operation, circulating lye N C / N T down to 0.1, after two months N C / N T down to 0.09, N after three months C / N T down to 0.08. The consumption of steam per ton is reduced to 0.26.

example 2

[0045] Example 2. Evaporating the N of the stock solution K The concentration is 160g / L, N C / N T is 0.14, and the discharge concentration of the falling film evaporator is controlled at N K It is 220g / L, forced discharge N K At 260g / L, two flashes are used for salt discharge operation, the forced discharge temperature is 105°C, once flashed to 95°C, flashed again to 90°C, flashed to N K The concentration is 295g / L. Add evaporative discharge salt to make seeds before flash evaporation, and the amount of seeds added is 80g / L. Final output N C / N T Dropped to 0.06, the washing cycle of the falling film evaporator is 20 days, and the washing cycle of the forced circulation evaporator is 5 days. After one month of operation, circulating lye N C / N T down to 0.1, after two months N C / NT down to 0.09, N after three months C / N T down to 0.08. The consumption of steam per ton is reduced to 0.26.

example 3

[0046] Example three, evaporate the N of stock solution K The concentration is 160g / L, N C / N T is 0.13, and the discharge concentration of the falling film evaporator is controlled at N K It is 220g / L, forced discharge N K At 270g / L, the method of one-time flash evaporation is used for salt discharge operation, the forced discharge temperature is 105°C, one-time flash evaporation to 90°C, and flash evaporation to N K The concentration is 290g / L. Before flash evaporation, add evaporative drainage salt as seeds, and the amount of seeds added is 30g / L. Final output N C / N T Dropped to 0.07, the washing cycle of the falling film evaporator is 25 days, and the washing cycle of the forced circulation evaporator is 4 days. After one month of operation, circulating lye N C / N T down to 0.09, after two months N C / N T down to 0.08. The consumption of steam per ton is reduced to 0.26.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com