Method and system capable of improving alumina seed decomposition rate

A technology for decomposition rate and alumina, applied in chemical instruments and methods, preparation of alkali metal aluminate/aluminum oxide/aluminum hydroxide, aluminum compounds, etc., can solve the problem of improving the decomposition rate of species and the viscosity of sodium aluminate solution Increase and shorten the decomposition time and other issues to achieve the effect of improving the decomposition rate of seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, rather than for limiting the protection scope of the present invention.

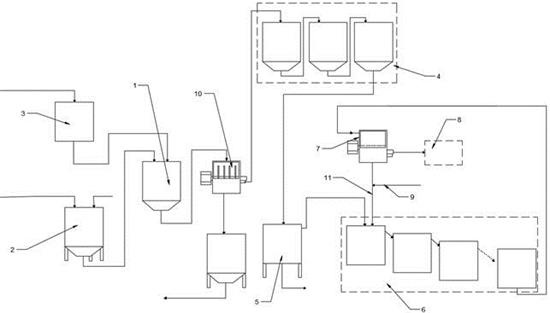

[0020] like figure 1 As shown in the figure, a method for improving the decomposition rate of alumina species disclosed in the present invention is characterized in that: the method utilizes the causticizing liquid produced by the causticizing system to be added to the species decomposition system 6 of the refined sodium aluminate solution, so that the The caustic concentration of the added caustic solution is 30-100g / L, the caustic ratio ɑk30-200, the caustic concentration of the refined sodium aluminate solution is 150-170g / L, the caustic ratio ɑk1.38-1.50, the sodium aluminate species is decomposed The initial decomposition temperature of the system 6 is 58-63 ° C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com