Additive applied to process for producing aluminum oxide by bayer method and preparation method of additive

A kind of alumina and Bayer technology, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of affecting alumina strength, refinement, affecting production sections, etc., to improve strength and particle size, improve decomposition rate, and species separation. The effect of increasing the decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Synthetic method of polystyrene-acrylamide-acrylic acid

[0041] Dissolve 20g of acrylamide in 40 mL of water, add 0.008g of chain extender MPMD (2-methyl-1,5-pentanediamine), slowly pour into a four-neck flask, slowly pour 1.2g of ST-80 emulsifier into a four-necked flask, then add styrene into the reaction system, blow in nitrogen for 20 minutes, add 0.010 g of azobisisobutyronitrile initiator, and react for 1 hour at 30°C under stirring at 300 r / min, and then Under 100r / min stirring, the polymerization reaction was completed in 4 hours;

[0042] Add 40% NaOH slowly into the above solution, and hydrolyze for 1 hour at 60°C; after the reaction, add 10% hydrochloric acid to adjust the pH to 4.5, add methanol until the product precipitates completely and separate; then use 3 Soak in twice the amount of toluene, remove the styrene copolymer, and dry to obtain polystyrene-acrylamide-acrylic acid;

[0043] The ST-80 emulsifier mentioned above is compounded...

Embodiment 2

[0047] Example 2 Preferred additive formula and preparation method thereof

[0048]

[0049]The above-mentioned preparation method of the polymer emulsion type decomposition additive used in the Bayer process alumina production process comprises the following steps:

[0050] (1) Mix polystyrene-acrylamide-acrylic acid with water, stir and dissolve in a water bath at 45°C to form a homogeneous liquid;

[0051] (2) Mix silyl ring carboxylic acid with alcohol, stir and dissolve into solution;

[0052] (3) Mix the product of step (1) and (2), under stirring, add NaOH to adjust the pH, and stir at high speed for 30 minutes to obtain the product.

[0053] At the initial stage of decomposition of the Bayer process sodium aluminate solution, the amount added at one time is 25 mg / L, and the laboratory results are shown in Table 2.

[0054]

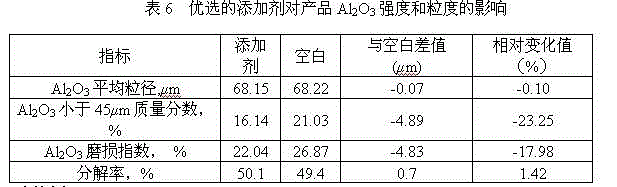

[0055] From the test results in Table 2, it can be seen that compared with the blank, the additive can increase the average particle siz...

Embodiment 3

[0058] The preferred additive formula is shown in Table 3, and the experimental results are shown in Table 4

[0059]

[0060] The above-mentioned preparation method of the polymer emulsion type decomposition additive used in the Bayer process alumina production process comprises the following steps:

[0061] (1) Mix polystyrene-acrylamide-acrylic acid with water, stir and dissolve in a water bath at 45°C to form a homogeneous liquid;

[0062] (2) Mix silyl ring carboxylic acid with alcohol, stir and dissolve into solution;

[0063] (3) Mix the product of step (1) and (2), under stirring, add NaOH to adjust the pH, and stir at high speed for 30 minutes to obtain the product.

[0064] At the initial stage of decomposition of the Bayer process sodium aluminate solution, the amount added at one time was 25 mg / L, and the laboratory results are shown in Table 4.

[0065]

[0066] The above-mentioned preparation method of the polymer emulsion type decomposition additive us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com