Gas distributor for circulating-flow scrubbing tower and design method of gas distributor

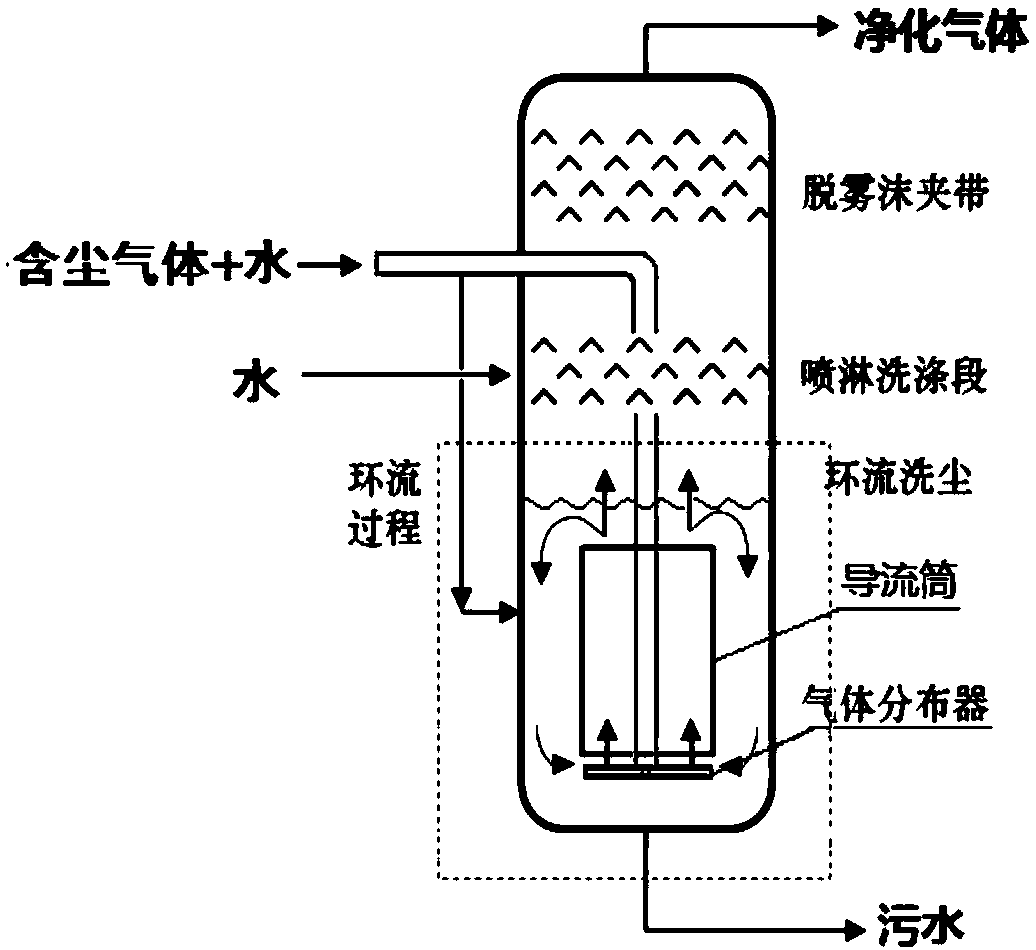

A technology of gas distributor and washing tower, which is applied in the direction of separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., which can solve the problems of inability to circulate, continuous discharge of solid slag, and multi-layer gas distribution branch pipe structure. Problems such as complex systems of solid particle deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

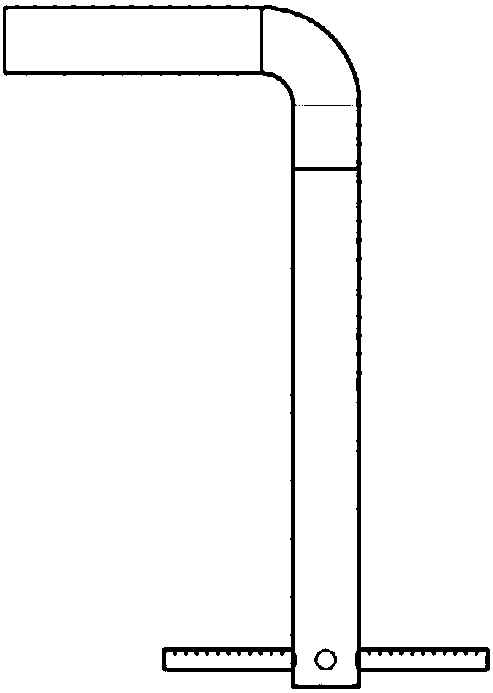

[0087] This embodiment provides a kind of dedusting gas distributor used in conjunction with the circulating water washing tower, its structure is as follows Figure 3a-Figure 3c , Figure 8 shown.

[0088] This gas distributor is made up of central inlet pipe 1 and four branch pipes 2, wherein, the end of central inlet pipe 1 is provided with blind plate, and, this blind plate is provided with drain hole 4, as Figure 3c As shown, the bottom end of the branch pipe 2 is also provided with a drain hole 4, and the above drain hole is Figure 12c circular through hole shown;

[0089] The four branch pipes 2 are all straight pipes, which are evenly distributed around the central air intake pipe 1 in a horizontal arrangement and diverge outward to form a branched structure;

[0090] The pipe wall of the branch pipe 2 is provided with a gas injection hole 3, such as Figure 8 As shown, the gas injection hole 3 is as Figure 12a The vertical through hole shown; the diameter of t...

Embodiment 2

[0107] This embodiment provides a gas distributor, its structure is as follows Figure 4a-Figure 4c , Figure 10 shown.

[0108] The gas injection holes provided on the branch pipe wall of this gas distributor are contraction type short tube nozzles 6, such as Figure 10 Shown, the sectional view of contraction type short pipe nozzle 6 is as Figure 12b As shown, the inlet aperture of the contracting short tube nozzle 6 is 6mm, and the outlet aperture is 4mm.

[0109] Other structures of the gas distributor are the same as the gas distributor in Example 1.

Embodiment 3

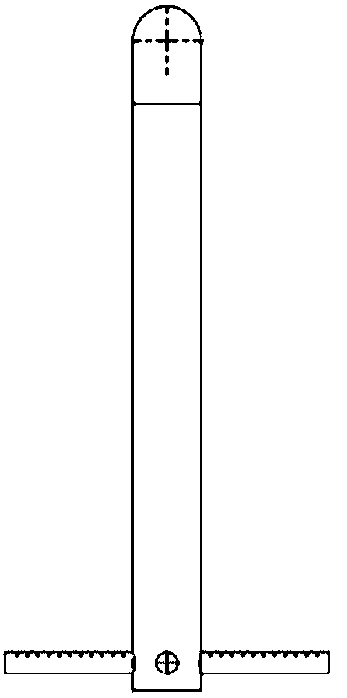

[0111] A kind of dedusting gas distributor used in cooperation with the circulating water washing tower provided by this embodiment, its structure is as follows Figure 5a-5c shown.

[0112] This gas distributor is made up of central inlet pipe 1 and four branch pipes 2, wherein, the end of central inlet pipe 1 is provided with blind plate, and, this blind plate is provided with drain hole, as Figure 5c As shown, the drain hole is Figure 12c circular through hole shown;

[0113] The main parts of the four branch pipes 2 are straight pipes, and the part connected to the central air intake pipe 1 is a small section of horizontal section; Appropriate acute angle) is evenly distributed around the central air intake pipe 1 and diverges outwards to form a dendritic structure; the bottom of the horizontal section of the branch pipe 2 is provided with a drain hole 4, such as Figure 5a , Figure 5b As shown, in addition, a drain hole 4 is provided at the end of the straight pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com