A method for advanced treatment of ASP flooding produced water with micro-bubbles

A ternary composite and advanced treatment technology, applied in filtration treatment, mining wastewater treatment, water/sewage treatment, etc., can solve problems such as unsatisfactory and unreachable, and achieve compact device, good effect, and small footprint of the device Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

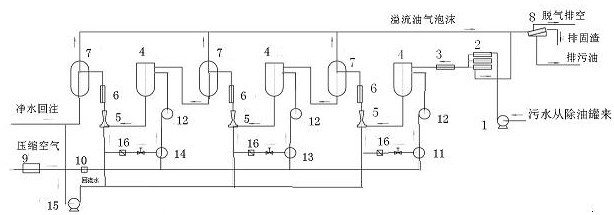

[0039] The invention takes the typical ASP flooding produced water in an oilfield as the object, and the treatment capacity is 10M 3 / h, sewage density 0.998g / cm 3 , crude oil density 0.86g / cm 3 , Sewage contains oil 100-180mg / L, contains suspended matter 22-50mg / L, polymer content 1100-1300mg / L, surfactant content 122-200mg / L, viscosity 4.9-5.2mPa.S, total salinity 14800 -20500mg / L, PH value 11.8-12.2, the particle size of oil droplets and suspended solids is mainly distributed below 20μm. The three-stage treatment units of 4μm, 10μm, and 25μm air microbubbles respectively carry out mixed adsorption, coalescence and cyclone separation treatment step by step. After treatment, the water quality reaches 5mg / L of oil content, 1mg / L of suspended solids, and the particle size of suspended solids 1μm water quality standard for reinjection water.

[0040] Below, in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0041] A te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com