A method and equipment for electron beam smelting polysilicon deoxidation and ingot coupling

An electron beam smelting and polysilicon technology, which is applied in the field of metallurgical smelting, can solve problems such as difficult operation, high risk, and high energy consumption, and achieve the effects of improving production efficiency, reducing time, and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

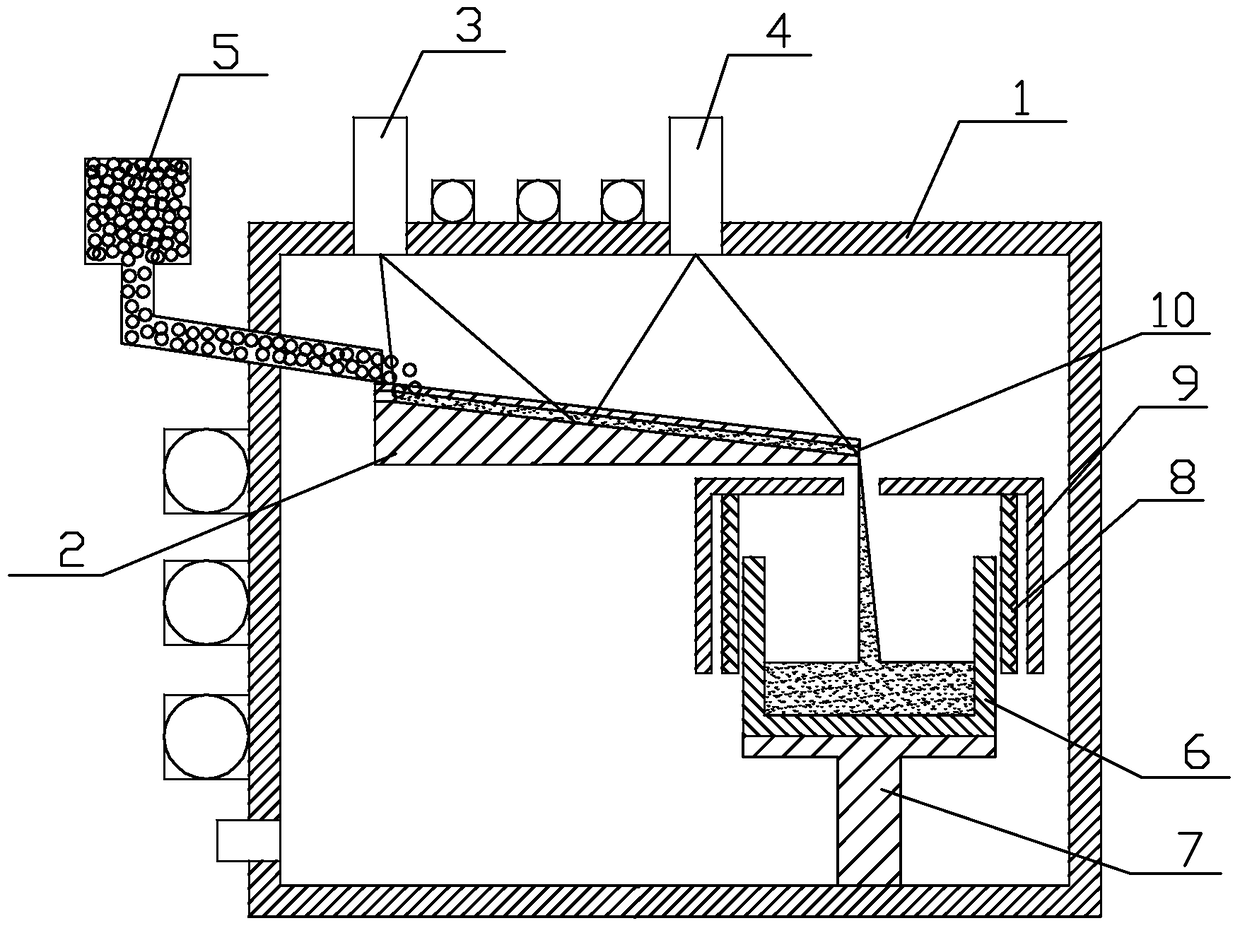

[0037] Such as figure 1 As shown, the equipment for electron beam smelting polysilicon deoxidation and ingot coupling includes a furnace body, and the furnace body 1 is provided with an electron beam smelting component and an ingot coupling component, wherein:

[0038] The electron beam smelting assembly includes a water-cooled conveyor belt 2 installed on the upper part of the furnace body. A feeding device 5 is arranged on the wall of the furnace body on one side of the water-cooled conveyor belt. The outlet of the feeding device is located above the water-cooled conveyor belt. The other side is inclined downward and has a diversion port, and a concave groove is opened on the water-cooling conveyor belt, which is used to guide the polysilicon liquid that is smelted and initially deoxidized to the direction of the ingot casting device, and passes through the guide on the water-cooling conveyor belt. The nozzle enters the ingot casting device, and the furnace body on the top o...

Embodiment 2

[0044] Adopt the device described in embodiment 1, carry out electron beam smelting polysilicon deoxidation and ingot coupling process, concrete steps are as follows:

[0045] (1) Loading and vacuuming: Clean and dry the polysilicon material with a particle size of 10-12mm, a purity of 99.996%, and an oxygen content of 20ppmw, then put it into the feeding device, and lay 6N polysilicon at the bottom of the quartz crucible of the ingot casting device Ingot bottom material, and vacuum the furnace to 3×10 -2 Pa, the vacuum degree of the electron gun is pumped to 4×10 -3 Pa, preheat the electron gun for 15 minutes;

[0046] (2) Preliminary oxygen removal: Continuously add the polysilicon material in step (1) through the feeding device to the water-cooled conveyor belt of the electron beam melting furnace, start the electron gun for melting, set the electron beam current of the electron gun for melting to 1200mA to melt and melt Preliminary removal of impurity oxygen in the polys...

Embodiment 3

[0050] Adopt the device described in embodiment 1, carry out electron beam smelting polysilicon deoxidation and ingot coupling process, concrete steps are as follows:

[0051] (1) Loading and vacuuming: Clean and dry the polysilicon material with a particle size of 24-30mm, a purity of 99.997%, and an oxygen content of 11ppmw, then put it into the feeding device, and lay 6N polysilicon at the bottom of the quartz crucible of the ingot casting device Ingot bottom material, and vacuum the furnace to 4×10 -2 Pa, the vacuum degree of the electron gun is pumped to 4.5×10 -3 Pa, preheat the electron gun for 13 minutes;

[0052] (2) Preliminary oxygen removal: Continuously add the polysilicon material in step (1) through the feeding device to the water-cooled conveyor belt of the electron beam melting furnace, start the electron gun for melting, set the electron beam current of the electron gun for melting to 800mA to melt and melt Preliminary removal of impurity oxygen in the poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com