Method for preparing soy sauce by recycling vegetable pickling brine

A brine and pickling technology, which is applied to the field of recovering vegetable pickling brine to prepare soy sauce, can solve the problems of poor flavor of soy sauce, incomparable aroma of soy sauce, and incomparability, achieve good quality and flavor, improve utilization rate, and realize efficient utilization of resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

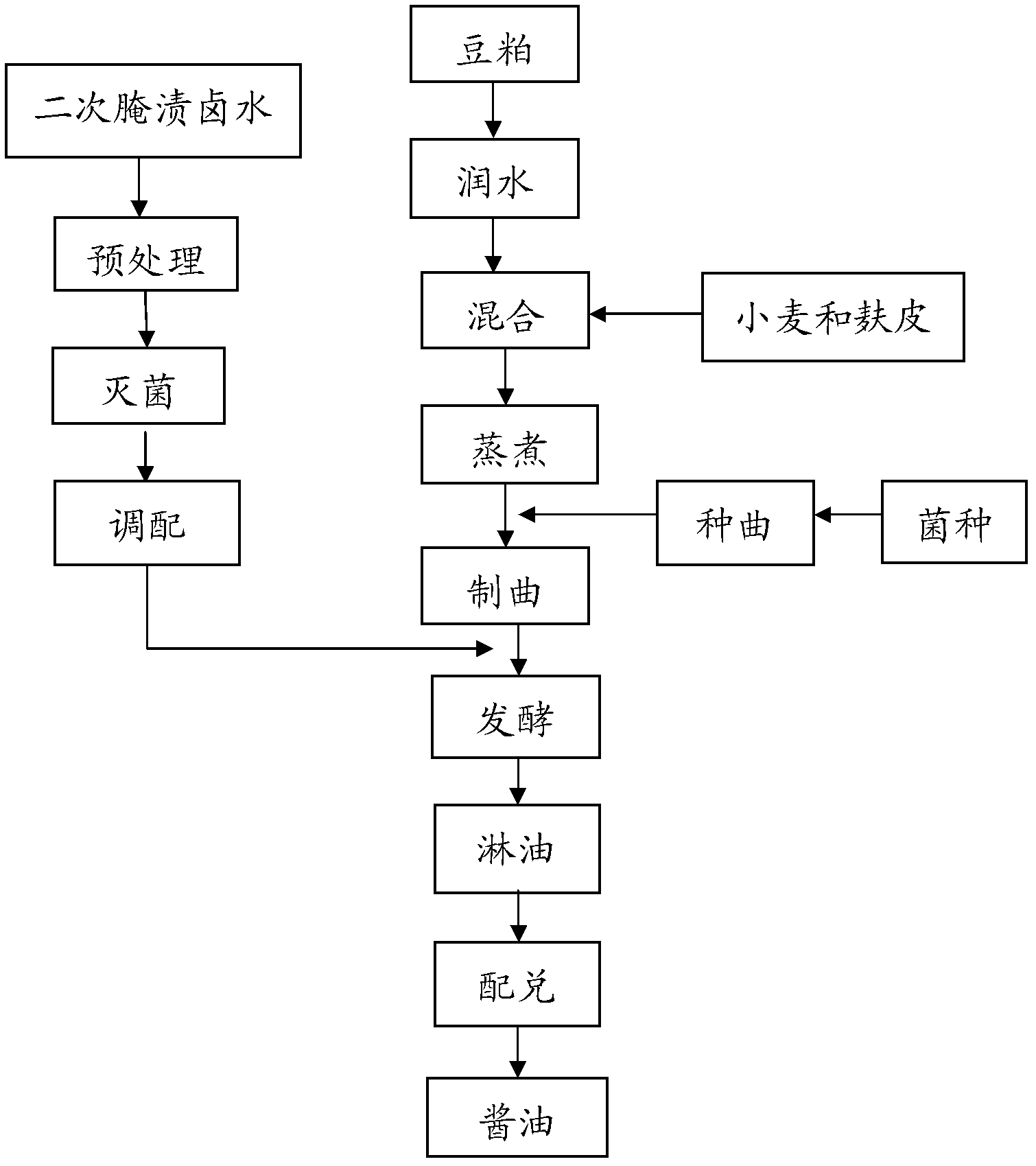

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1 Secondary recovery of pickled brine

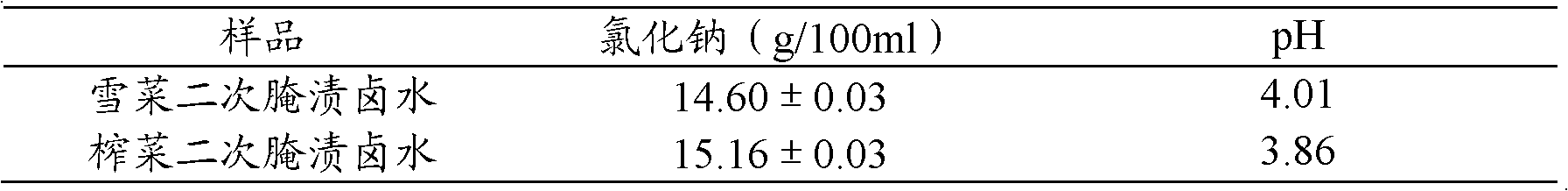

[0038] Secondary pickling brine of pickled vegetables and second pickling brine of pickled mustard were recovered from Hangzhou Jingyangguan Xiaoshan Sauce Co., Ltd. in large tanks; the sodium chloride content and the pH value of the brine were tested, and the results are shown in Table 1.

[0039] When using the low-salt solid-state method to ferment soy sauce, the amount of sodium chloride added in the koji is set at 13°Bé (14.68g / 100ml). According to Table 1, the sodium chloride content of the two samples is equivalent to the amount of sodium chloride that should be added to the soy sauce koji, so the secondary pickling brine can be sterilized, and the precipitate can be directly added to the soy sauce koji in proportion Let it ferment.

[0040] Table 1 Sodium chloride content and pH value of secondary pickling brine

[0041]

Embodiment 2-3

[0042] The production of embodiment 2-3 soy sauce

[0043] (1) Get the secondary pickling brine of pickled cabbage that is recovered in Example 1, get the supernatant, and boil for 30 minutes; then get the supernatant to obtain salt brine;

[0044] (2) Get the soybean meal, add hot water at 62°C to moisturize; wherein, the amount of water is 0.90kg per kilogram of soybean meal;

[0045] (3) Pour the crushed wheat and bran into it and mix with the moistened soybean meal; wherein the weight ratio of soybean meal, wheat and bran is 3:1:1;

[0046] (4) Place it in a container for cooking, and let it cool to 32°C after discharging;

[0047] (5) adding commercially available Yuyuan brand soy sauce koji essence to the cooled material to make koji;

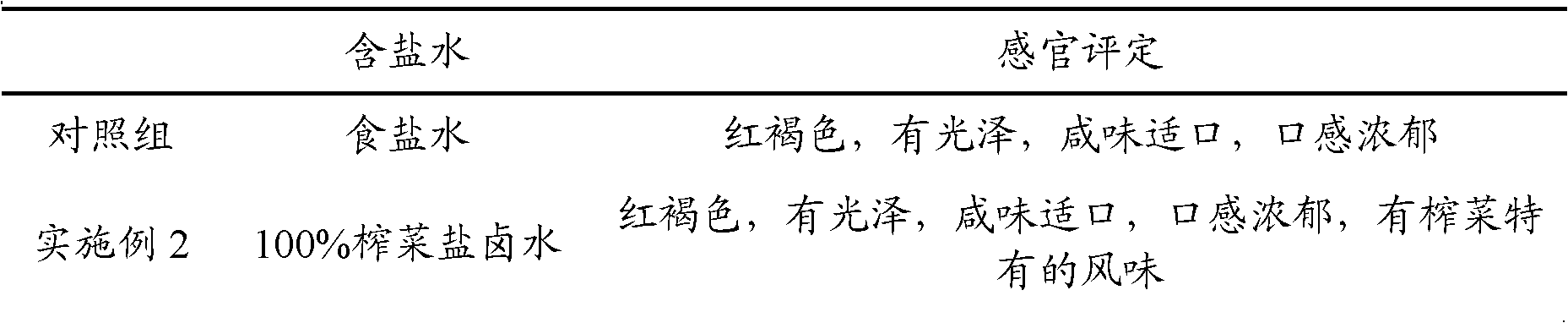

[0048] (6) Add 1.125 times the weight of salt water into the koji, stir and then ferment in the fermentation tank; wherein, all the salt water is brine, or a mixture of brine and salt water (the weight ratio of the two is 1:1) ;

[00...

Embodiment 4-5

[0051] The production of embodiment 4-5 soy sauce

[0052] The soy sauce production is carried out according to the steps of Example 2-3, wherein, the secondary pickling brine of pickled cabbage in step (1) is replaced by the secondary pickling brine of pickled mustard recovered in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com