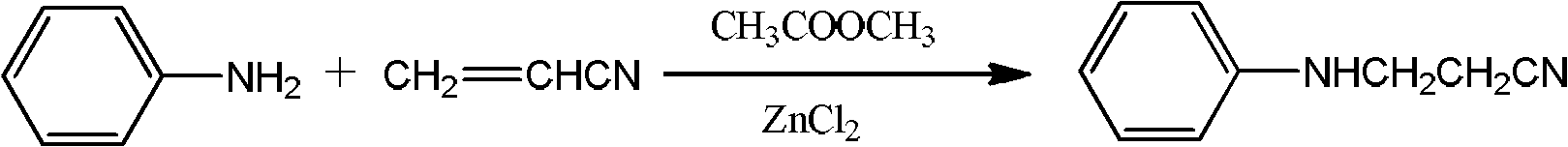

Clean production method of N-cyanoethylaniline

A technology of cyanoethylaniline and clean production, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as refractory high COD wastewater, reduce discharge, eliminate adverse effects, and design rationally Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Put 4,200 parts of bottom water into the reactor, start stirring, and then add 300 parts of zinc chloride, 12 parts of hydroquinone, 150 parts of sodium bicarbonate, 100 parts of hydrochloric acid (mass concentration 31%), 2700 parts of aniline, acrylonitrile 1740 parts, after heating up to 60°C, start to heat up slowly, uniformly heat up to 95°C in about 10 hours, keep warm for 10 hours, turn off stirring, let stand for 45 minutes, separate the water layer to the mother liquor water storage tank, and produce 4800 parts of mother liquor water. After the separation, 12 parts of sodium bicarbonate was added to the reaction product with stirring until the pH value was about 4. Acrylonitrile was recovered under vacuum to obtain 195 parts of a mixture of acrylonitrile and water, including 70 parts of acrylonitrile and 125 parts of water. The reaction product recovered from acrylonitrile is sucked into the aniline evaporator, heated to 100°C, flushed with 100°C steam, and 800...

Embodiment 2

[0026] Drop into 4500 parts of the mother liquor water of embodiment 1, start stirring, drop into 300 parts of zinc chloride successively, 12 parts of hydroquinone, 150 parts of sodium bicarbonate, 100 parts of hydrochloric acid (mass concentration 31%), 2700 parts of aniline, acrylonitrile 1740 parts, after heating up to 60°C, start to heat up slowly, uniformly heat up to 95°C in about 10 hours, keep warm for 10 hours, turn off stirring, let stand for 45 minutes, separate the mother liquor water to the mother liquor water storage tank. Produce 4800 parts of mother liquor water, after separation, 12 parts of sodium bicarbonate are added to the reaction product under stirring until the pH value is about 5. . 195 parts of a mixture of acrylonitrile and water were recovered under vacuum, including 70 parts of acrylonitrile and 125 parts of water. Inhale N-cyanoethylaniline into the aniline evaporator, raise the temperature to 125°C, pour in steam at 125°C, distill 800 parts of t...

Embodiment 3

[0029]Drop into 4700 parts of the mother liquor water of embodiment 2, start stirring, drop into 300 parts of zinc chloride successively, 12 parts of hydroquinone, 150 parts of sodium bicarbonate, 100 parts of hydrochloric acid (mass concentration 31%), 2700 parts of aniline, acrylonitrile 1740 parts, after heating up to 60°C, start to heat up slowly, uniformly heat up to 95°C in about 10 hours, keep warm for 10 hours, turn off stirring, let stand for 45 minutes, separate mother liquor water to mother liquor water storage tank, and produce 4800 parts of mother liquor water. After the separation, 13 parts of sodium bicarbonate was added under stirring until the pH value was about 6. 195 parts of a mixture of acrylonitrile and water were recovered under vacuum, including 70 parts of acrylonitrile and 125 parts of water. Inhale N-cyanoethylaniline into the aniline evaporator, raise the temperature to 150°C, pour in steam at 150°C, distill 800 parts of distillate, and take samples...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com