Nickel-gold electroplating process of PCB

A technology of printed circuit board and nickel-gold electroplating, applied in the direction of secondary processing of printed circuit, etc., can solve the problem of inability to realize nickel-gold electroplating of printed circuit board, etc., and achieve the effects of excellent appearance, high feasibility and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

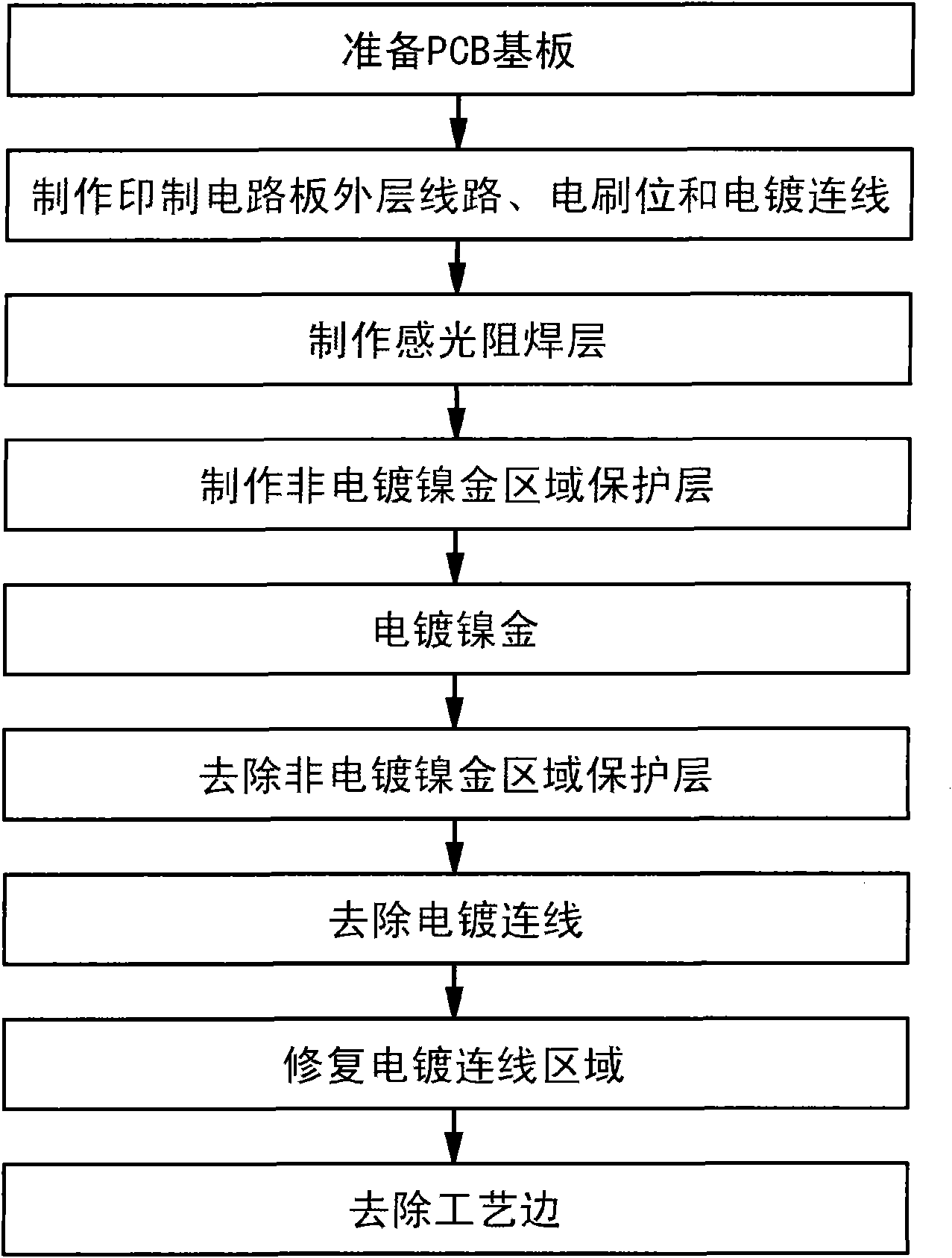

[0034] like Figure 1 to Figure 6 Shown, the nickel-gold electroplating process of printed circuit board in the present preferred embodiment comprises the following steps:

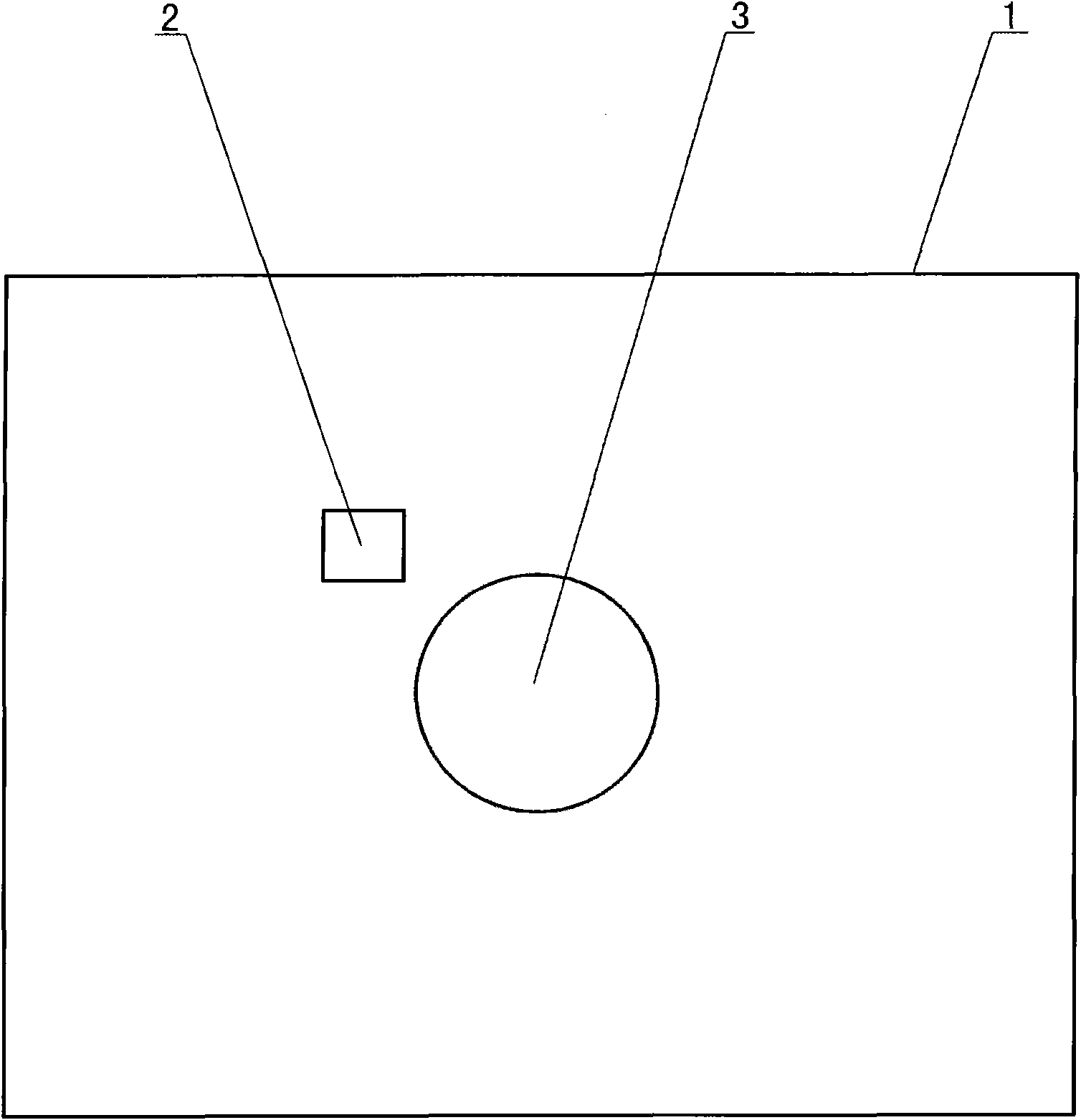

[0035] (1) Prepare PCB substrate 1: as figure 2 As shown, the above-mentioned PCB substrate 1 is a single-layer PCB substrate, and the above-mentioned PCB substrate 1 is provided with a packaging pad 2 and an area 3 to be electroplated with nickel and gold, and the above-mentioned area 3 to be electroplated with nickel and gold is located in the non-edge area of the surface of the PCB substrate 1;

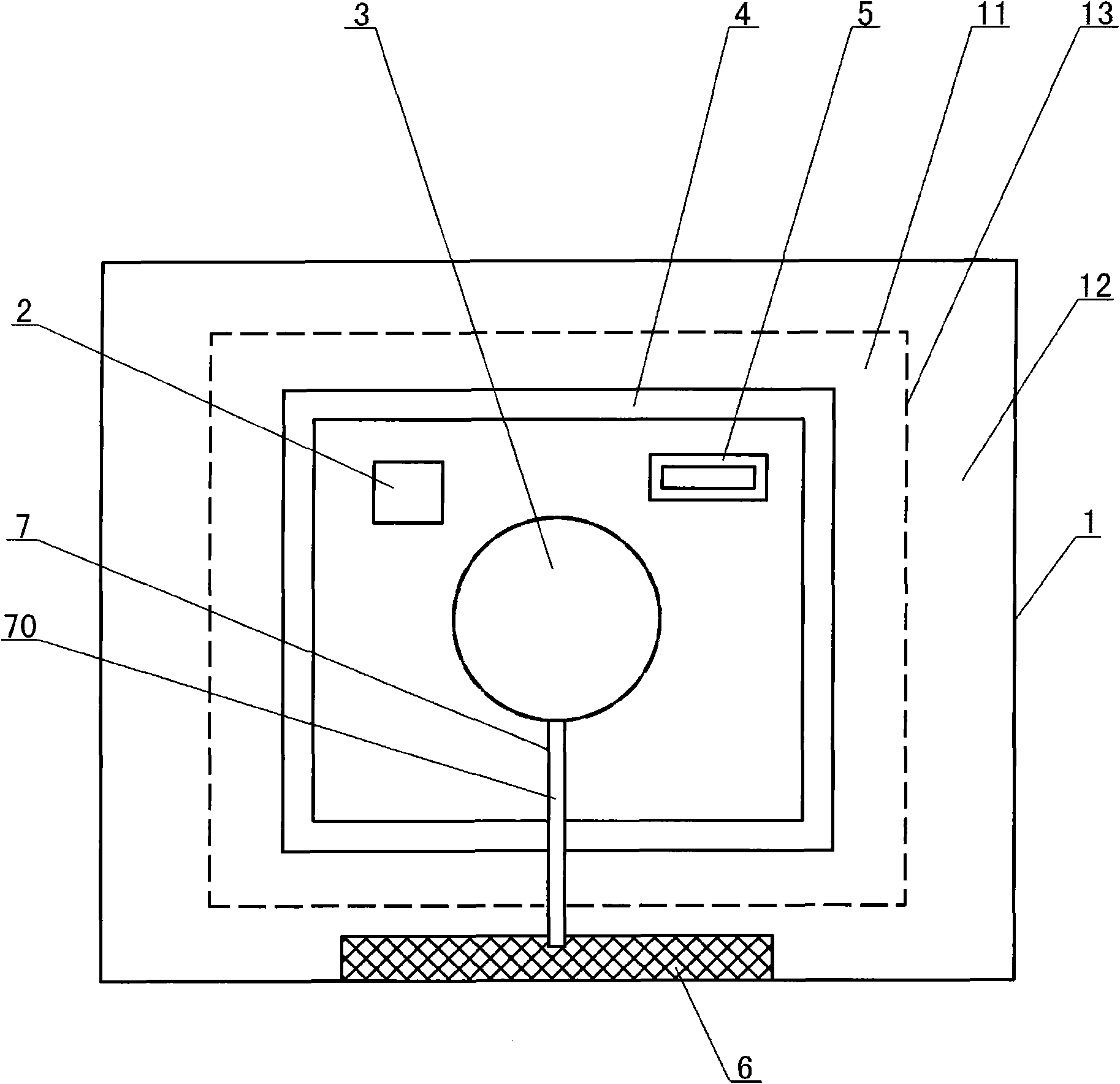

[0036] (2) Make printed circuit board outer circuit 4, 5, brush position 6 and electroplating connection 7: as image 3 As shown, the PCB substrate 1 is divided into a printed circuit board area 11 and a process edge 12, and the boundary line between the printed circuit board area 11 and the process edge 12 is 13; by etching, the printed circuit board area 11 is made. Make circuit board outer layer circuit...

Embodiment 2

[0046] Embodiment 2 is basically the same as Embodiment 1, the difference between the two is:

[0047] like Figure 7 As shown, the PCB substrate 1 in Embodiment 2 is a multilayer PCB substrate. The above-mentioned multilayer PCB substrate, before making the outer layer circuit of the printed circuit board, the brush position and the electroplating connection, completes the internal circuit board according to the conventional printed circuit board process. Layer circuit production, different circuit layer lamination, and then drilling and through the process of electroless copper plating and electroplating copper to realize the conduction of the interlayer circuit; when making the photosensitive solder resist layer, the plug-in mounting hole 10 of the above-mentioned multi-layer PCB substrate belongs to non- In the exposed area, when the exposure is performed, the photosensitive solder resist layer on the plug-in mounting hole 10 is not exposed and is removed by developing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com