Method for promoting anaerobic digestion of residual activated sludge to generate methane by pretreatment combined electrochemical technology

An electrochemical technology and anaerobic digestion technology, which is applied in the field of pretreatment combined with electrochemical technology to promote anaerobic digestion of residual activated sludge to produce methane, can solve the problems of long anaerobic fermentation time and low efficiency, and improve biodegradability , to achieve the effect of reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

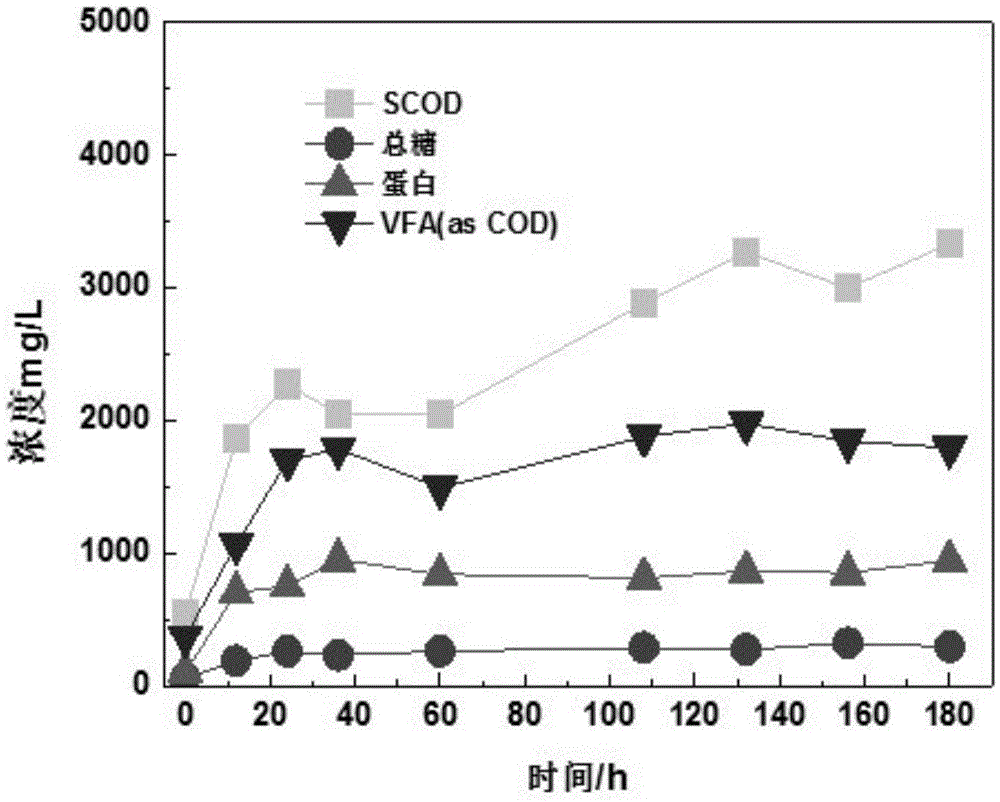

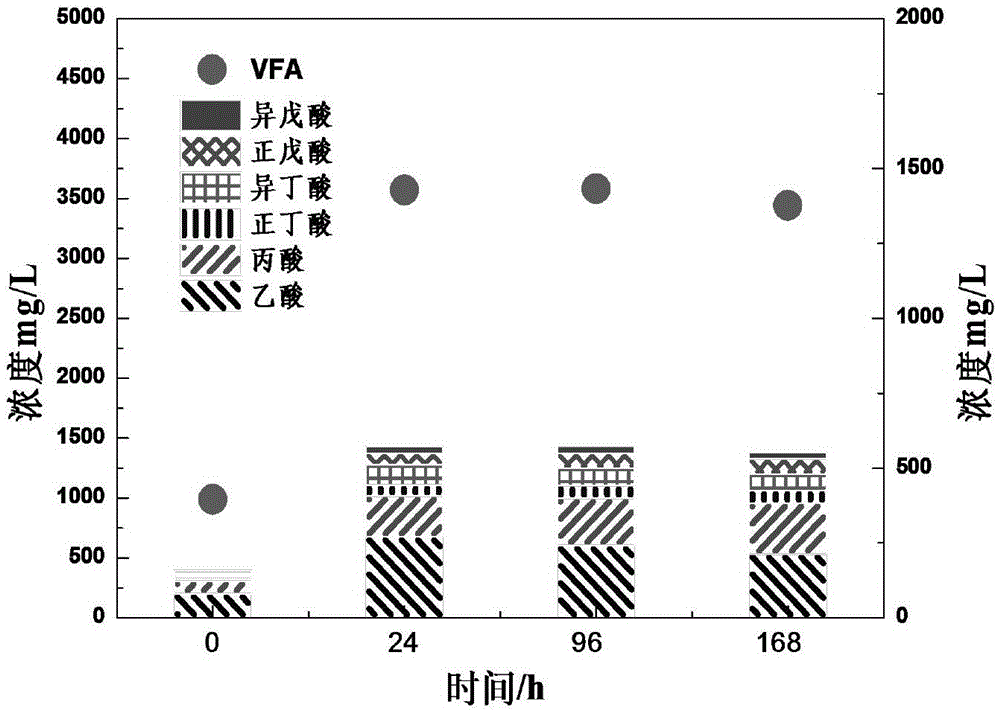

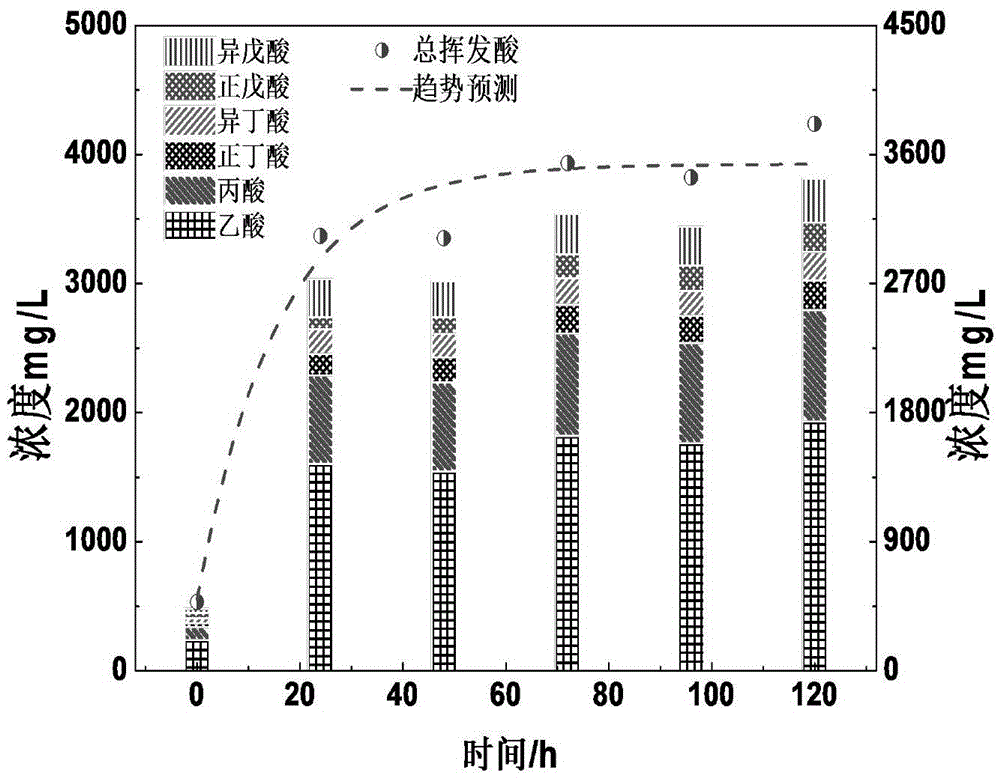

[0031] Example 1 A method of pretreatment combined with electrochemical technology to promote anaerobic digestion of excess activated sludge to produce methane

[0032] The sludge was taken from the remaining activated sludge in the secondary settling tank of a sewage treatment plant in Harbin.

[0033] The steps are

[0034] 1) Acclimatization and cultivation of anode carbon brushes in microbial electrolytic cells

[0035] The anode carbon brush is made of the anode with a diameter of 25.0mm, a length of 25.0mm, and a surface area of 0.22m 2The carbon brushes are made by first soaking the carbon brushes in acetone for 24 hours, and then burning them in a muffle furnace at a temperature of 450°C for 30 minutes. The cathode is a carbon cloth coated with a Pt / C catalytic layer, only one side of the carbon cloth is coated with a catalytic layer, and the area of the catalytic layer is 7.0cm 2 With breathable waterproof layer.

[0036] Under the conditions of high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com