Vacuum electroosmosis sludge drying equipment and method thereof

A technology of sludge drying and electroosmosis, applied in electrochemical sludge treatment, chemical instruments and methods, sludge treatment, etc., can solve the problems of large dosage and low efficiency of sludge drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

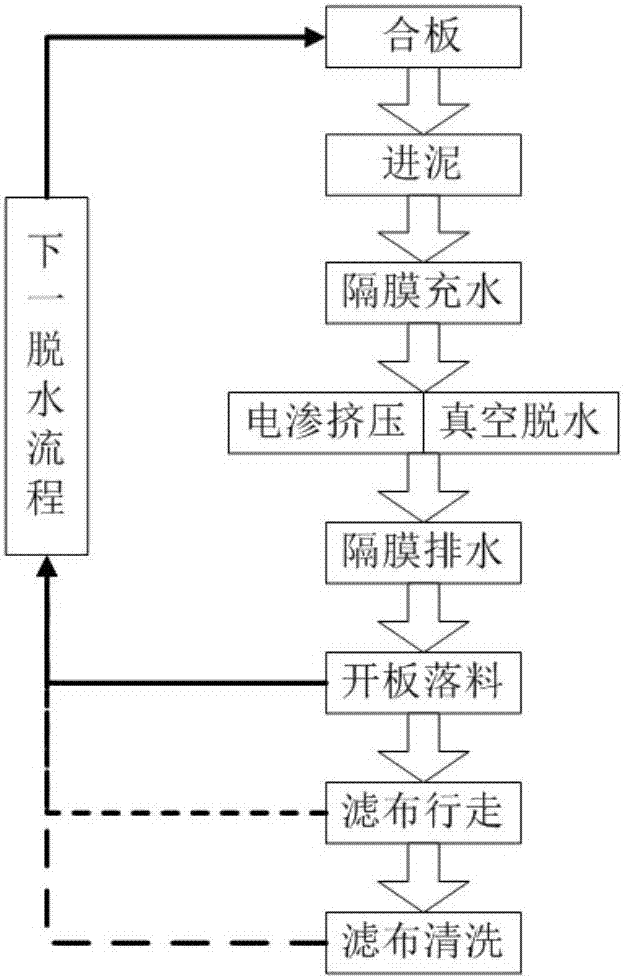

[0116] Process flow of the present invention such as figure 1 As shown, first merge, compress and lock the filter chamber unit; then enter the mud to form a mud cake; the water bag is filled with water to mechanically squeeze the mud cake; power is applied to carry out electroosmotic dehydration of the mud cake, and at the same time the vacuum Dehydration; then the rubber diaphragm drains water; finally open the relatively airtight filter chamber, drop the material and remove the cake; the filter cloth walking and filter cloth cleaning can be selected according to the filter cloth conditions; proceed to the next dehydration cycle.

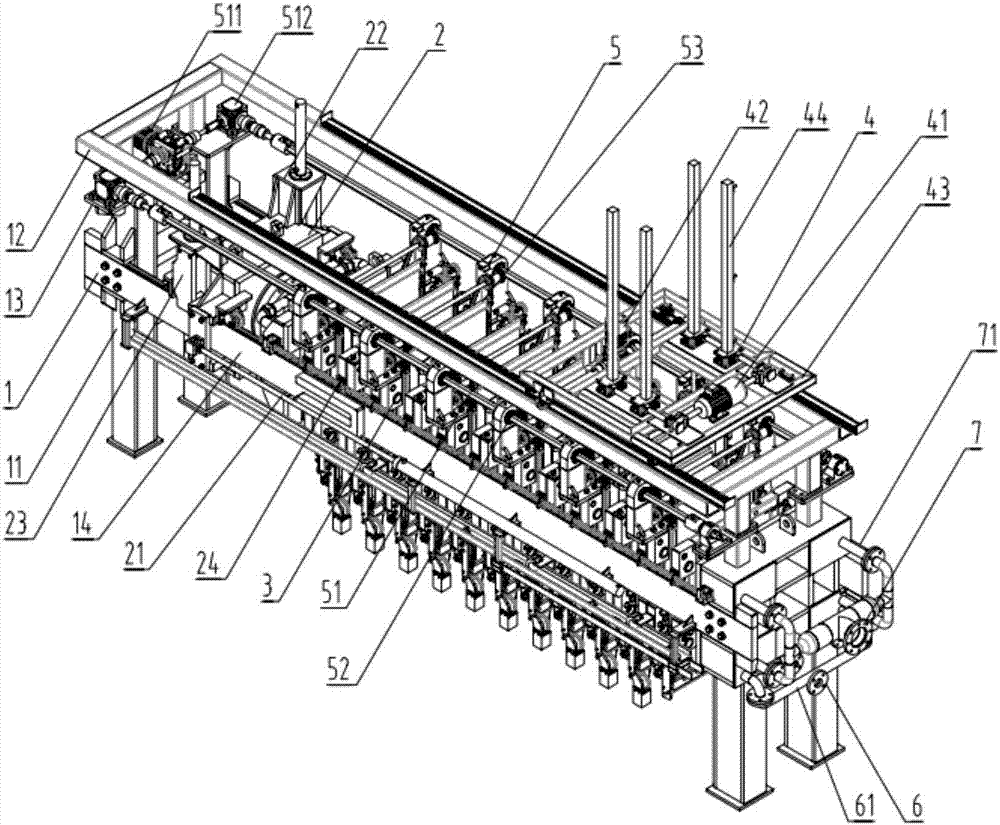

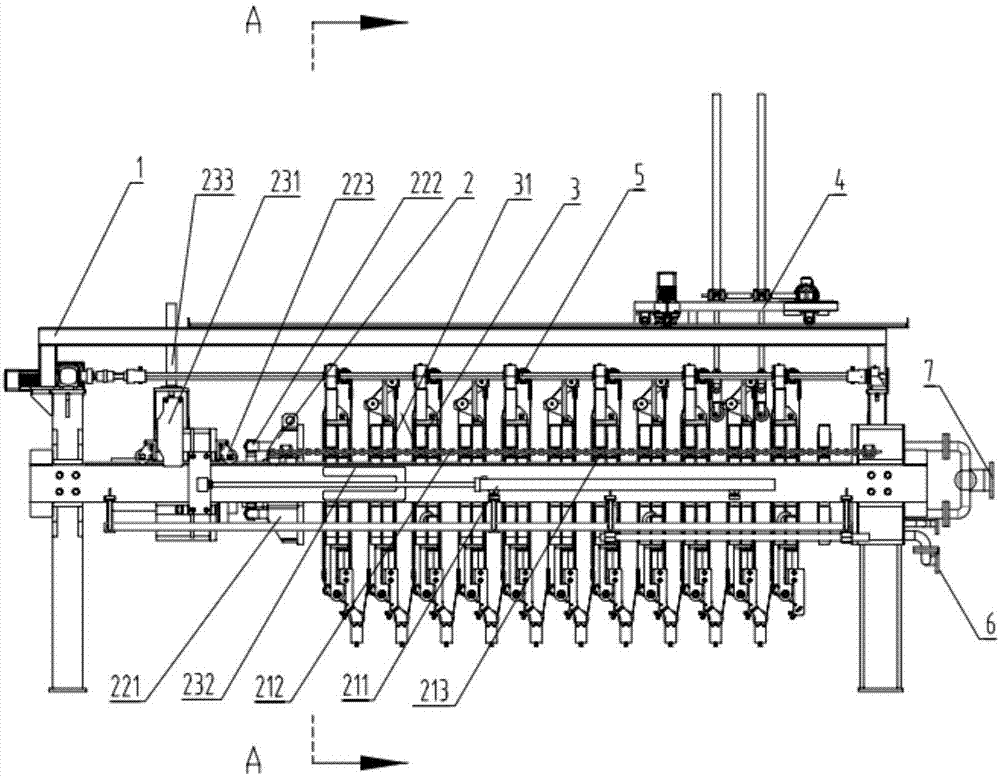

[0117] A vacuum electroosmotic sludge drying equipment, such as figure 2 As shown, it includes a support platform 1, a mechanical extrusion device 2, an electro-osmosis dehydration device 3 and a vacuum low-temperature evaporation dehydration device 6; the mechanical extrusion device 2, the electro-osmosis dehydration device 3 and the vacuum low-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com