Efficient electroosmotic sludge dehydrator

A sludge dewatering machine and sludge dehydration technology, applied in the direction of electrochemical sludge treatment, water/sludge/sewage treatment, sludge treatment, etc., can solve the problems of lack of dehydration efficiency and slow promotion, and achieve easy promotion, Effect of improving dehydration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

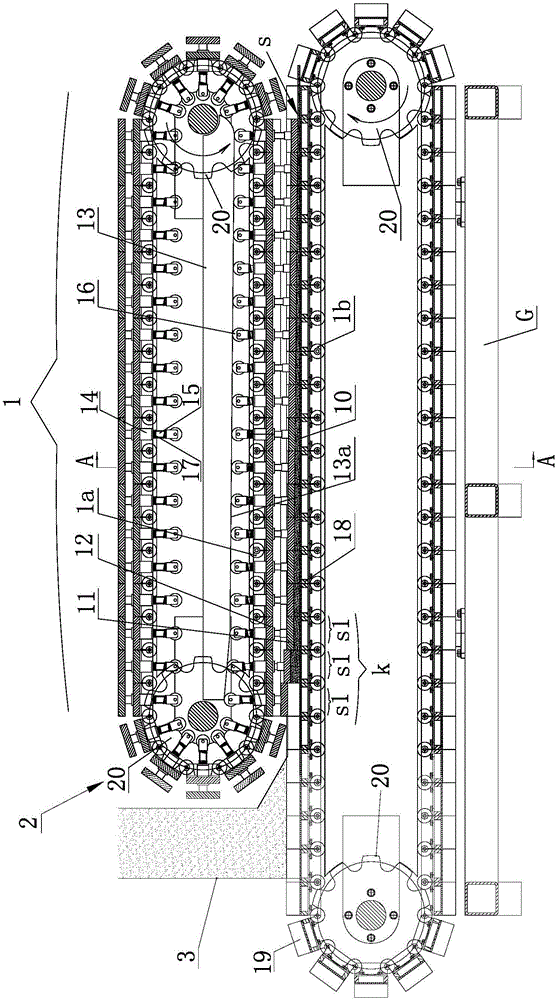

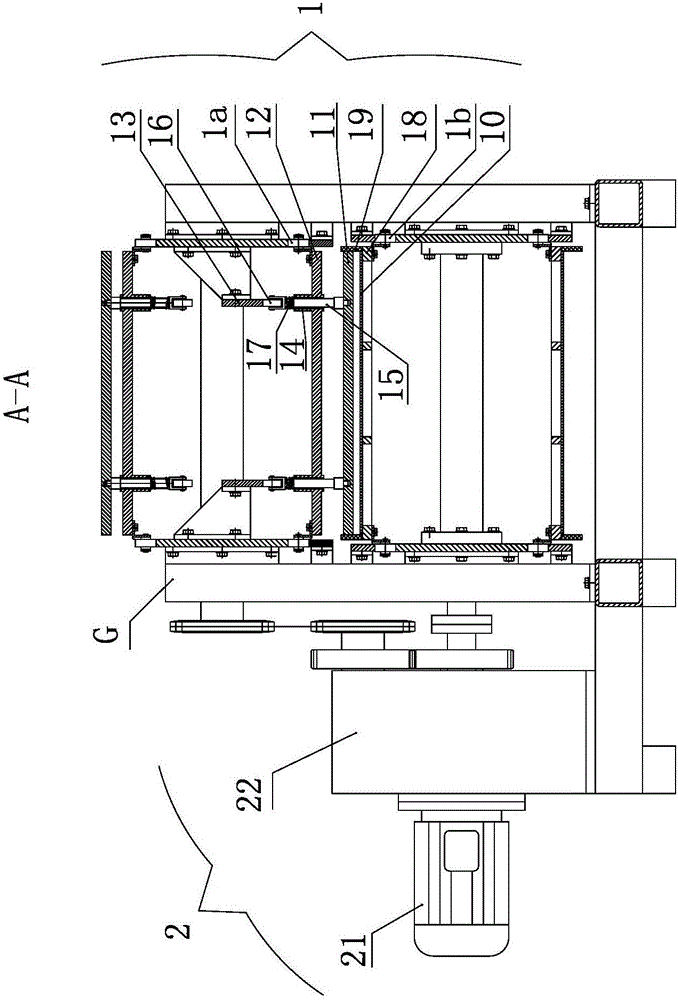

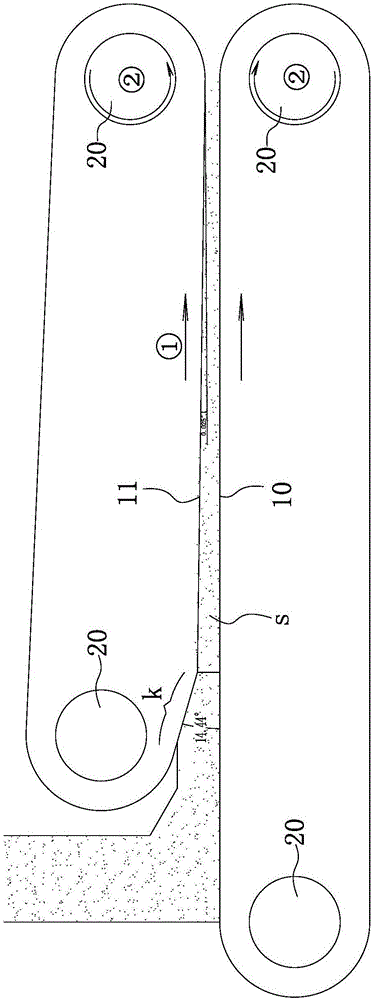

[0033]The inventors of the present applicant have unexpectedly discovered in a large number of studies that when the sludge first enters the wedge-shaped extrusion zone, it is relatively loose, and there will be some air in the middle. It will be dehydrated. Only when the sludge is squeezed to a certain degree of compactness, the current increases, and the sludge will be dehydrated. The wedge angle of the wedge-shaped extrusion zone is generally relatively small, and the sludge has to enter a rather long section. It takes only a certain distance to squeeze to a certain degree of compactness, which is a waste of time. If the sludge can be squeezed quickly when it first enters the wedge-shaped extrusion zone, the sludge can reach a certain degree of compactness in a short time. Increase the length of the effective extrusion zone, thereby improving the dehydration efficiency, and the test proves that it can be increased by about 30%. Based on this principle, the original sludge d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com