Method for enhancing anaerobic digestion and methane production of excess sludge by zero-valent iron and activated carbon

A technology for anaerobic digestion and excess sludge, applied in electrochemical sludge treatment, chemical instruments and methods, biological sludge treatment, etc., can solve the problems of low organic matter degradation rate, low methane production efficiency, limited promotion and application, etc. , to achieve the effect of promoting decomposition, increasing activity and strengthening contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

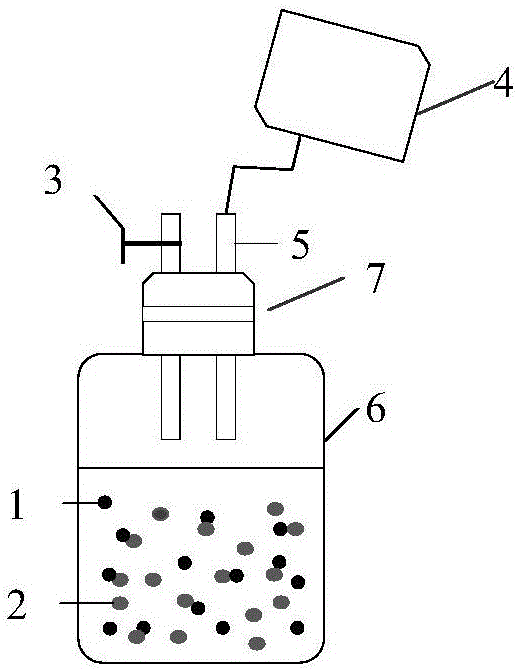

[0030] A method for simultaneously adding zero-valent iron (ZVI) and activated carbon (AC) to strengthen the anaerobic digestion of excess sludge to produce methane, comprising the following steps:

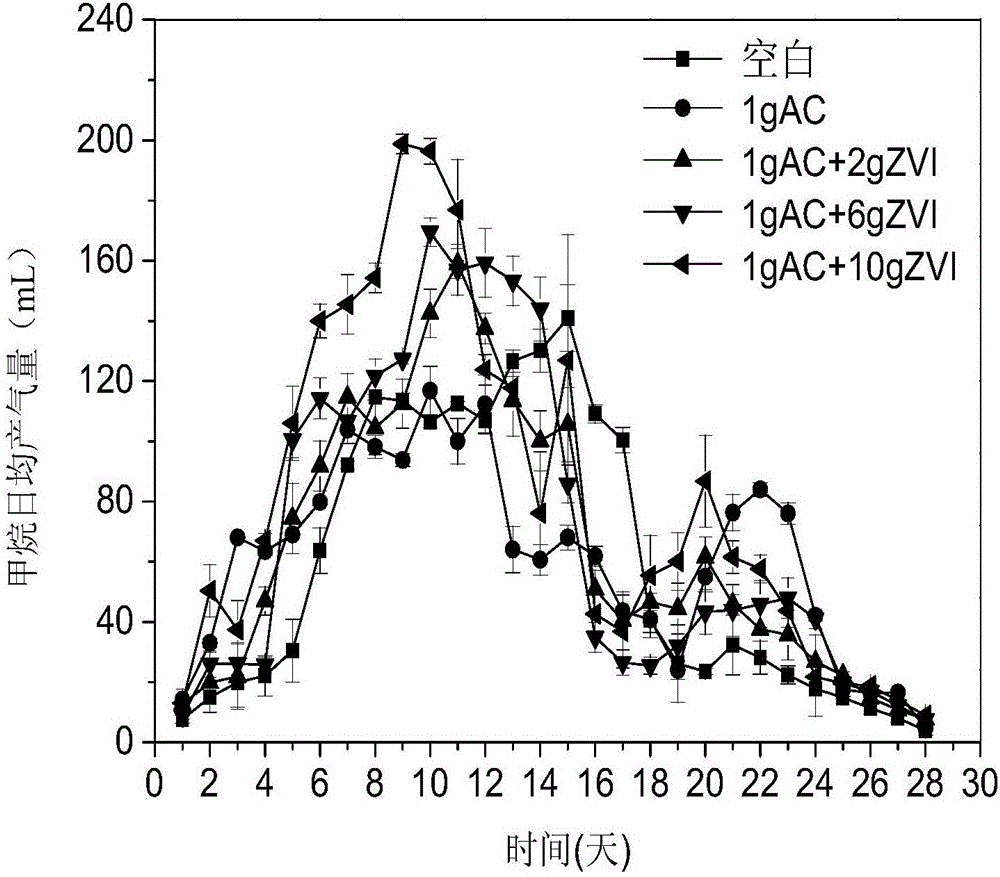

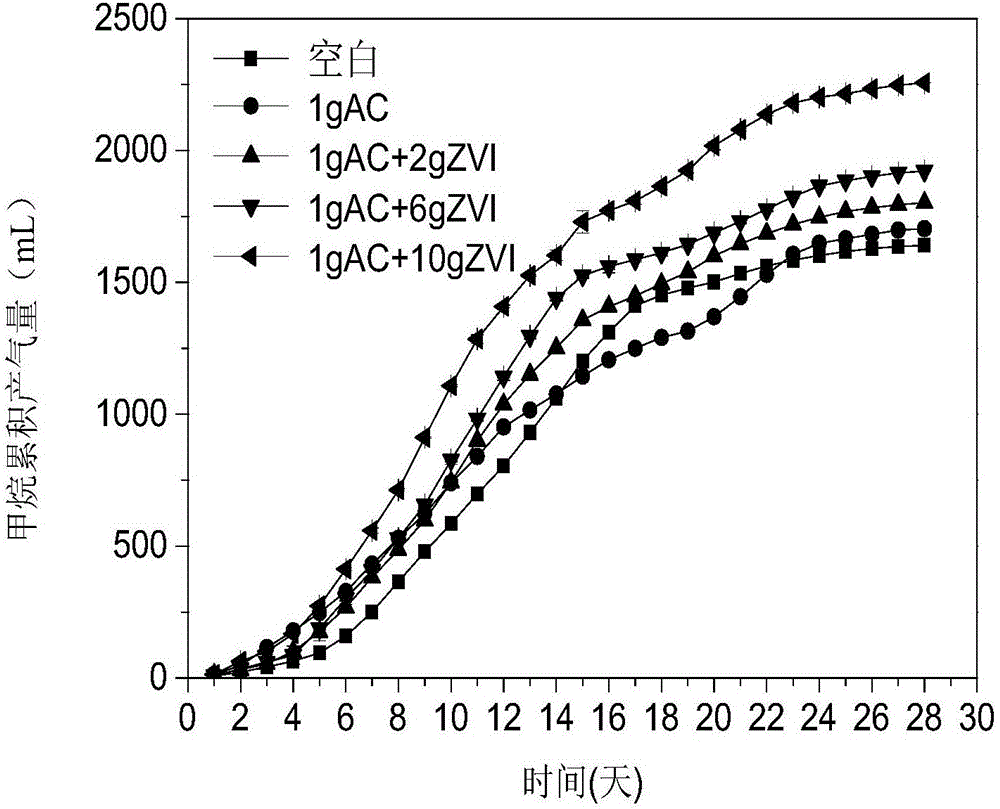

[0031] (1) Zero-valent iron powder is commercially available analytical pure zero-valent iron powder (the manufacturer is Tianjin Fuchen Chemical Reagent Factory), and the size of zero-valent iron powder is 60-100 mesh; Activated carbon is commercially available powdered activated carbon (without Phosphorus) (Zhengzhou Niute Agricultural Technology Co., Ltd.), the size is 100-200 mesh; from Guangzhou Lijiao Sewage Treatment Plant, the solid content after dehydration is 75-85%. Sludge) was adjusted to a solid content of 14% with distilled water to obtain adjusted excess sludge; the adjusted excess sludge was mixed with inoculated sludge at a volume ratio of 2:1, and the pH was measured to be 6.5, without adjustment pH and then use distilled water to make the solid content after mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com