Device and method for degrading excess sludge through pretreatment-EGSB-microorganism-electrochemistry integration

A microbial electrochemistry, -EGSB- technology, which is applied in electrochemical sludge treatment, chemical instruments and methods, electrochemical-biological combined treatment, etc., can solve problems such as secondary environmental pollution, achieve low treatment costs, and improve cracking efficiency. , good synergistic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

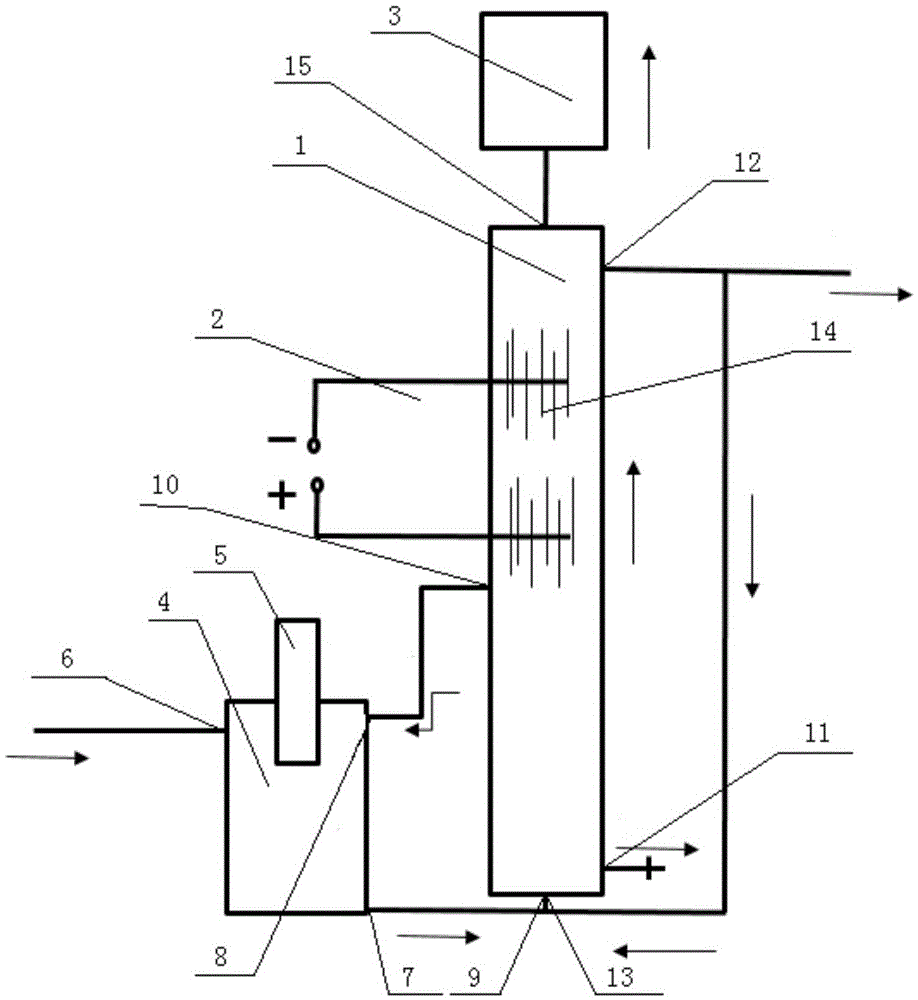

[0038] A pretreatment-EGSB-microbial electrochemical combined residual sludge degradation device, such as figure 1 As shown, it consists of crushing-anaerobic combined preprocessor, EGSB anaerobic processor 1, microbial electrochemical reactor 2 and gas collector 3;

[0039] Among them, the combined crushing-anaerobic preprocessor is composed of anaerobic reactor 4 and ultrasonic equipment 5, and ultrasonic equipment 5 can also be replaced by mechanical homogenizing equipment, high-pressure injection equipment and other crushing equipment; ultrasonic equipment 5 and other crushing equipment can be used as needed set inside or outside the anaerobic reactor 4;

[0040] The anaerobic reactor 4 is provided with a feed inlet 6, a discharge outlet 7 and a feed outlet 8; the EGSB anaerobic processor 1 is provided with a slurry inlet 9, a slurry outlet 10, a mud outlet 11, and a water outlet 12 , the water return port 13 and the exhaust port 15, in the present embodiment, the slurry ...

Embodiment 2

[0044] A pretreatment-EGSB-microbial electrochemical combined excess sludge degradation device, the structure is the same as that of Example 1, the difference is:

[0045] (1) The microbial electrochemical reactor 2 is an MFC reactor, and the reactor is externally connected to an electric energy collection device;

[0046] (2) The volume ratio of the anaerobic reactor 4 to the EGSB anaerobic processor 1 is 1:1.5; the cathode and anode poles of the MFC reactor are distributed at 1 / 2-3 / 4 of the height of the EGSB anaerobic processor 1.

Embodiment 3

[0048] Utilize the device of embodiment 1 to carry out the method for surplus sludge degradation, comprise the steps:

[0049] (1) Broken-anaerobic joint pretreatment

[0050] The excess sludge with a concentration of 20g / L is input into the crushing-anaerobic combined preprocessor from the feed port on the anaerobic tank, and the anaerobic sludge in the anaerobic reactor is used to anaerobically digest the excess sludge for a short time to kill A large number of aerobic microorganisms in the dead activated sludge change the properties of the sludge and reduce the difficulty of sludge cracking. The ratio of the mass of the remaining sludge to the anaerobic sludge is 2:1; at the same time, the ultrasonic wave of the crushing equipment is used to disperse the sludge Bacterial micelles break bacterial cells and decompose macromolecules. Ultrasound is a probe-type generating device with a frequency of 20KHZ. The time for each ultrasound is 0.5h, and the time interval between two u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com