Harmless and recycling treatment method and process for oily sludge

A treatment method and sludge technology, which is applied in the field of harmless and resource-based treatment, achieves the effects of large treatment volume, reduced treatment cost and solution to pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

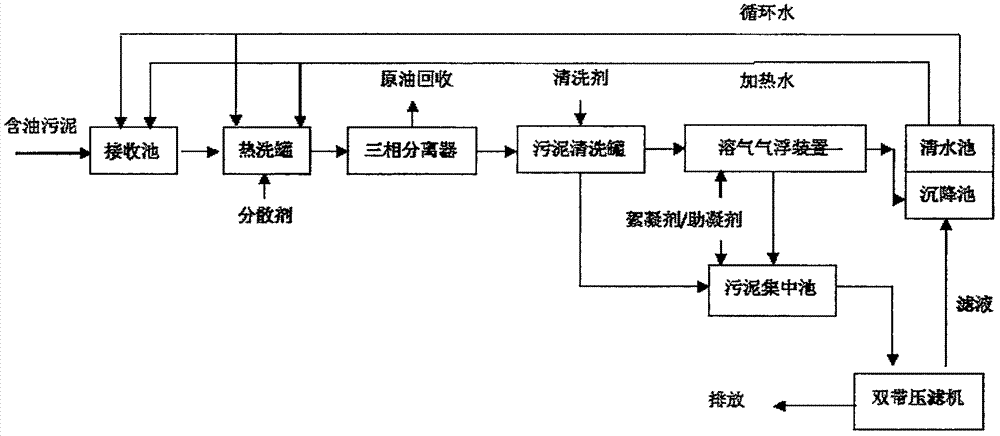

Image

Examples

Embodiment 1

Embodiment 2

[0035] Example 2: The untreated sludge at the on-site sludge treatment station of an oil production plant in the Yanchang Oilfield contains 21.99wt% oil, 42.93wt% water, and 35.08wt% impurities. The specific treatment method is the same as in Example 1, that is: The sludge is diluted 2 times by circulating water in the receiving tank, and enters the hot washing tank after reaching a fluid state. The oily sludge is further diluted to 5 times the original sludge in the hot washing tank, and the oily sludge mixture is heated to 60°C. The dispersant enters the sludge cleaning tank, and then the crude oil is separated from the sludge by adding the cleaning agent; after the sludge is collected in the sludge concentration tank, it is processed by a double-belt filter press, and a bio-accelerator is added outside. Transported to the drying yard, the treated oily sludge contains 0.30wt% oil, 37.87wt% water, and 61.83wt% impurities. The heavy metal ions meet the discharge standard, and t...

Embodiment 3

[0036] Example 3: The sludge containing 25.18wt% oil, 32.27wt% water, and 42.55wt% impurity after tempering treatment at the on-site sludge treatment station of an oil production plant in the Yanchang Oilfield. The specific treatment method is the same as in Example 1, that is, by The oily sludge is diluted 2 times by circulating water in the receiving tank, and enters the hot washing tank after it reaches a fluid state. The oily sludge is further diluted to 5 times of the original sludge in the hot washing tank, and the oily sludge mixture is heated to 80°C and put into the tank. Add dispersant, enter the sludge cleaning tank, and then separate the crude oil from the sludge by adding cleaning agent; after the sludge is collected in the sludge concentration tank, it is processed by a filter press, added with an accelerator, and transported to In the drying yard, after treatment, the oily sludge contains 0.275wt% of oil, 38.89wt% of water, and 60.835wt% of impurities. The heavy ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com