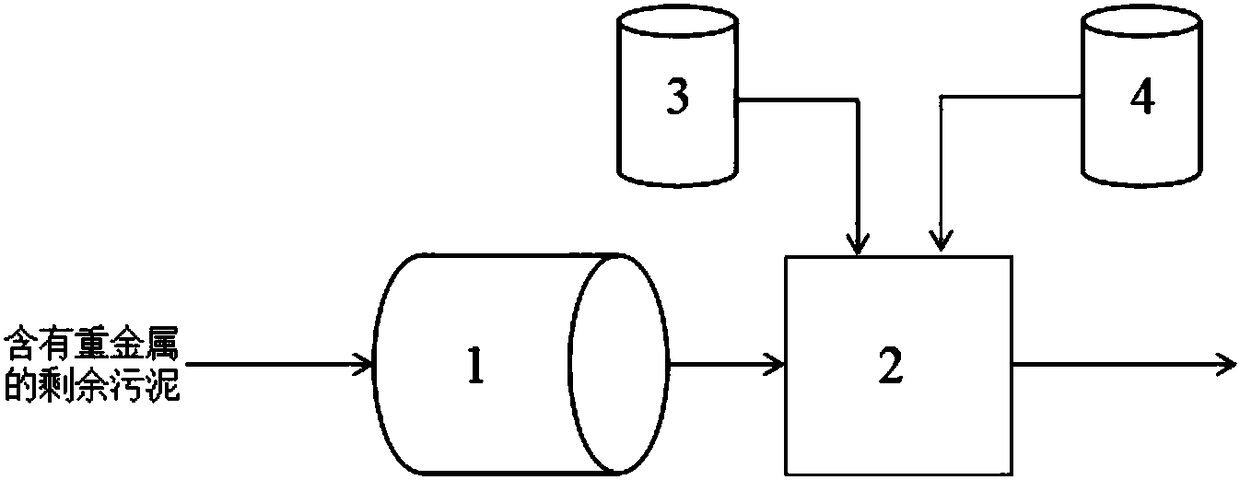

Heavy metal sludge harmless treatment system and method

A technology for harmless treatment of heavy metal sludge, applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., to achieve easy microbial degradation, promote anaerobic fermentation, and promote anaerobic fermentation of sludge Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Ultrasonic pretreatment of heavy metal sludge samples (pretreatment conditions: power 1.0W / ml, time 25min) was added to the conical flask of the anaerobic reactor with a volume of 3000ml, and the pH of the reactor was adjusted to 9.0. Nitrogen is used to realize anaerobic environment, the reactor is sealed, and the anaerobic fermentation is carried out for 8 days. The stirring speed of the anaerobic fermentation is 120r / min, and the temperature of the anaerobic reactor is controlled to be 40±0.5°C. Stabilizes heavy metals in sludge through alkaline treatment and the action of abundant microorganisms in the anaerobic reactor. The heavy metal removal efficiency was 36.3%.

Embodiment 2

[0037] Ultrasonic pretreatment of heavy metal sludge samples (pretreatment conditions: power of 1.2W / ml, time of 30min) was added to the conical flask of the anaerobic reactor with a volume of 3000ml, and the pH of the reactor was adjusted to 9.5. Nitrogen is used to realize anaerobic environment, the reactor is sealed, and the anaerobic fermentation is carried out for 8 days. The stirring speed of the anaerobic fermentation is 125r / min, and the temperature of the anaerobic reactor is controlled to be 38±0.5°C. Stabilizes heavy metals in sludge through alkaline treatment and the action of abundant microorganisms in the anaerobic reactor. The heavy metal removal efficiency was 49.3%.

Embodiment 3

[0039]Ultrasonic pretreatment (pretreatment conditions: power 1.2W / ml, time 35min) was added to the conical flask of the anaerobic reactor with a volume of 3000ml, and the pH of the reactor was adjusted to 10.0. Nitrogen is used to realize anaerobic environment, the reactor is sealed, and anaerobic fermentation is carried out for 8 days. The stirring speed of anaerobic fermentation is 120r / min, and the temperature of anaerobic reactor is controlled to be 35±0.5°C. Stabilizes heavy metals in sludge through alkaline treatment and the action of abundant microorganisms in the anaerobic reactor. The heavy metal removal efficiency was 64.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com