Method for treating sludge and promoting reduction of sludge by using ferrate

A ferrate and sludge reduction technology, applied in sludge treatment, biological sludge treatment, dehydration/drying/thickened sludge treatment, etc., can solve the serious problem of excess sludge disposal and does not involve sludge treatment process , dewatered sludge moisture content reduction and other issues, to shorten the anaerobic digestion time, reduce the difficulty of sludge treatment and disposal, and promote the effect of sludge dehydration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

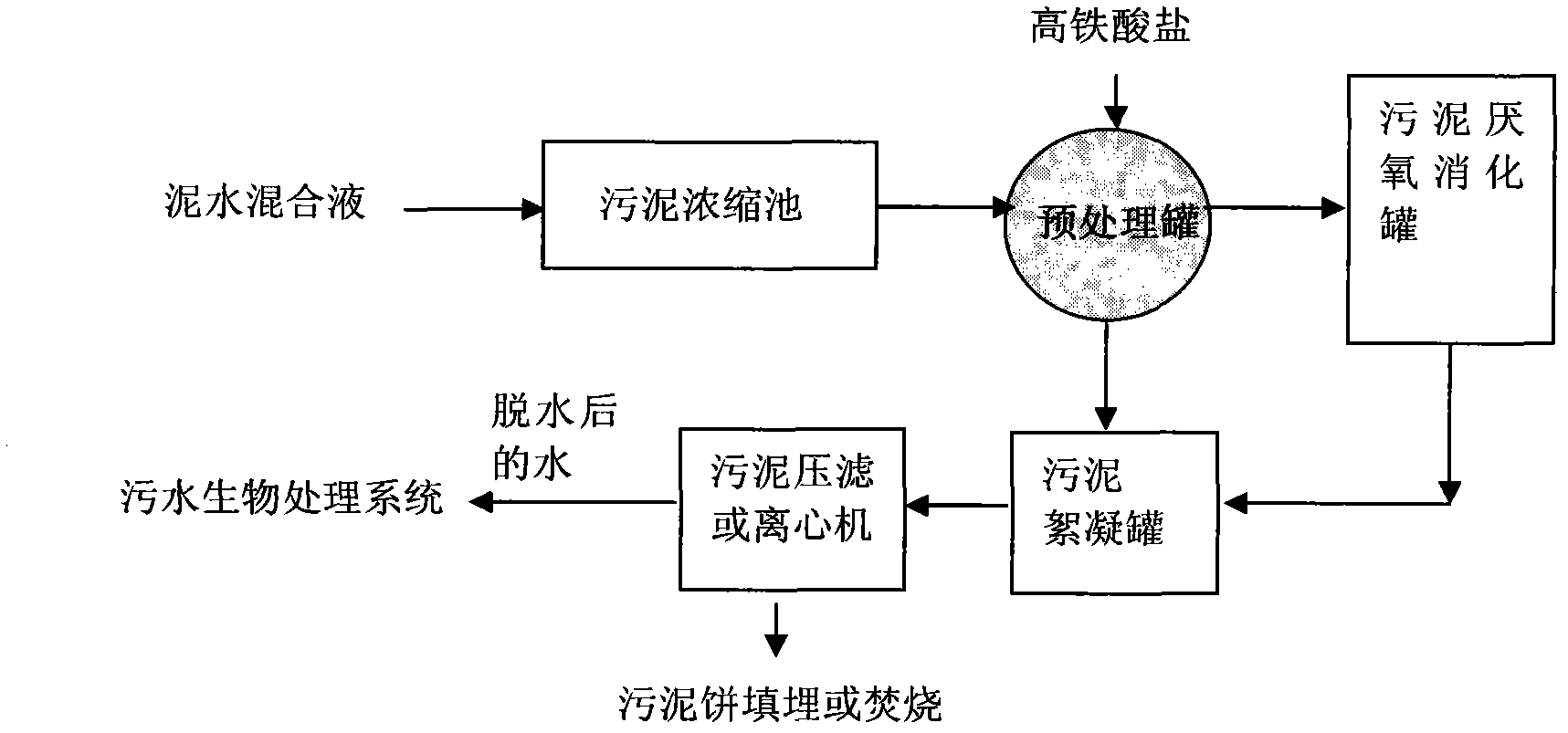

Image

Examples

Embodiment 1

[0022] Embodiment 1: adopt the method of the present invention to treat the excess sludge of a certain sewage treatment plant in Ningbo, operate under normal temperature, the mass ratio of potassium ferrate and excess sludge is 0.2: 1, oxidation reaction is 5 minutes, sludge press filtration dehydration. The moisture content of the sludge is reduced from 99% to 65%, and the specific resistance of the sludge is reduced from 4.67×10 11 m / kg reduced to 0.37×10 11 m / kg, without the sludge treated with potassium ferrate, the moisture content of the sludge after pressure filtration and dehydration is 81%, and the specific resistance of the sludge is 1.59×10 11 m / kg, the amount of flocculant was reduced from 0.7% (dry basis) to 0.55% (dry basis).

Embodiment 2

[0023] Embodiment 2: adopt the method of the present invention to treat the excess sludge of a certain sewage treatment plant in Ningbo, operate under normal temperature, the mass ratio of potassium ferrate and excess sludge is 0.5: 1, oxidation reaction 10 minutes, sludge pressure filtration dehydration. The water content of the sludge is reduced from 99% to 63%, and the specific resistance of the sludge is reduced from 5.73×10 11 reduced to 0.33×10 11 , and the sludge that has not been treated with potassium ferrate has a water content of 80% after pressure filtration and dehydration, and a specific resistance of the sludge is 2.39×10 11 , The amount of flocculant was reduced from 0.7% (dry basis) to 0.6% (dry basis).

Embodiment 3

[0024] Embodiment 3: adopt the method of the present invention to deal with the excess sludge of Ningbo certain enterprise sewage treatment station, operate under normal temperature, the mass ratio of potassium ferrate and excess sludge is 1.0: 1, oxidation reaction is 30 minutes, and sludge Anaerobic digestion. The sludge anaerobic digestion time was changed from 25 days to 12 days, and the biogas production increased by 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com