A kind of glyoxal cross-linked polymer modified high amylopectin and its preparation method and application

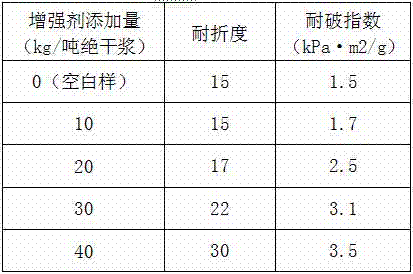

A technology of high amylopectin and cross-linked polymers, applied in textiles and papermaking, coatings, paper coatings, etc., can solve problems such as limited strength indicators such as bursting strength, reduced dehydration rate of wet paper webs, and difficulties in white water closed circulation. Achieve a good paper enhancement effect, improve the first-pass retention rate, and improve the system retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

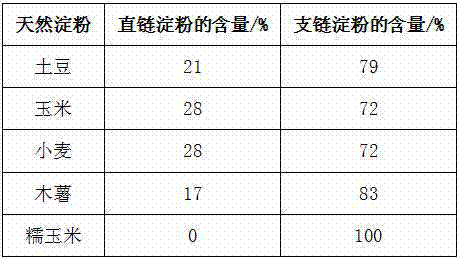

Image

Examples

specific Embodiment 1

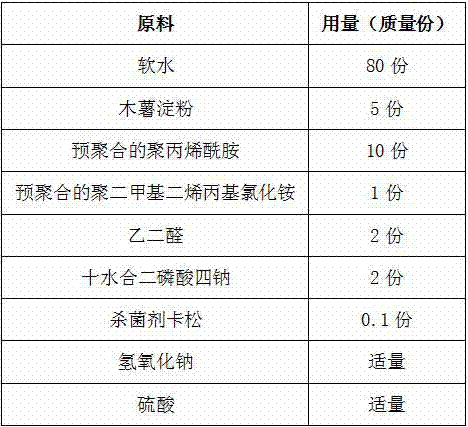

[0031] This example provides a preparation method for glyoxal cross-linked polymer modified high amylopectin, the main raw materials used and the amount of feed are shown in the following table:

[0032]

[0033] The preparation method comprises the following steps:

[0034] In a 20 L reactor equipped with a stirrer, a thermometer, and a reflux condenser, mix 1275 g of tapioca starch and soft water in a mass ratio of 6.25:100, and heat the reactor to 120°C and stir until the tapioca starch is completely dissolved. , and then lower the temperature to below 60°C.

[0035] Take out the cassava starch solution and add it to a 2000ml flask equipped with a turbine stirrer and an RTD temperature sensor. Add polyacrylamide homopolymer (molecular weight: 10,000 Daltons) 135 g, polydimethyldiallyl ammonium chloride homopolymer (molecular weight 10,000 Daltons) 15 g, tetrasodium diphosphate decahydrate 30 g, glyoxal 30 g, stir well and add appropriate amount of sodium hydroxide and ...

specific Embodiment 2

[0041] This example provides a preparation method for glyoxal cross-linked polymer modified high amylopectin, the main raw materials used and the amount of feed are shown in the following table:

[0042]

[0043] The preparation method comprises the following steps:

[0044] In a 20L reactor equipped with a stirrer, a thermometer, and a reflux condenser, mix 1275 g of waxy cornstarch and soft water in a mass ratio of 6.25:100, and heat the reactor to 120°C and stir until the waxy cornstarch is completely Dissolve, and then cool down to below 60°C.

[0045] Take out the waxy corn starch solution and add it to a 2000ml flask equipped with a turbo stirrer and an RTD temperature sensor. Add polyacrylamide homopolymer (molecular weight: 10,000 Daltons) at a stirring speed of 120 RPM and a temperature of 40°C. 135g, polydimethyldiallyl ammonium chloride homopolymer (molecular weight 10,000 Daltons) 15g, tetrasodium diphosphate decahydrate 30g, glyoxal 30g, stir well and add appr...

specific Embodiment 3

[0051] The monomer of polyacrylamide in specific example 1 is replaced by one selected from acrylamide, N,N-dimethylacrylamide, N,N-diethylacrylamide, N-vinylformamide or A variety of nonionic monomers; the monomer of polydimethyldiallyl ammonium chloride in specific embodiment 2 is replaced by dimethyldiallyl ammonium chloride, dimethylaminoethyl acrylate Methyl chloride quaternary ammonium salt, dimethylaminoethyl methacrylate methyl chloride quaternary ammonium salt, diethylaminoethyl acrylate methyl chloride quaternary ammonium salt, diethylaminoethyl methacrylate methyl quaternary ammonium chloride, quaternary methyl chloride of dimethylaminopropyl acrylamide, quaternary methyl chloride of dimethylaminopropyl methacrylamide, benzyl quaternary chloride of dimethylaminoethyl acrylate Ammonium salt, benzyl chloride quaternium of dimethylaminoethyl methacrylate, benzyl chloride quaternium of diethylaminoethyl methacrylate, benzyl chloride quaternium of diethylaminoethyl metha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com