Sludge two-phase anaerobic treatment process based on sulfonyl porphyrin iron catalyst Fenton-like system

A sulfonic acid-based porphyrin iron, anaerobic treatment technology, applied in biological sludge treatment, oxidation treatment of sludge, iron organic compounds, etc. Problems such as bond cleavage process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

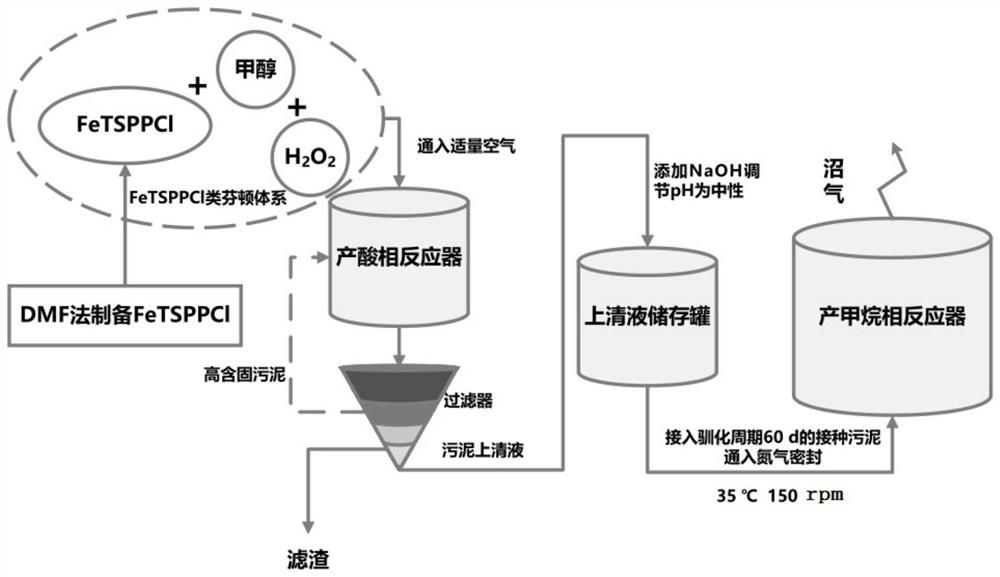

[0037] A sludge two-phase anaerobic treatment process based on sulfonic acid porphyrin iron catalyst Fenton system, the process flow chart is as follows figure 1 shown, including the following steps:

[0038] S1. Accurately weigh 4 mg of sulfonic acid porphyrin iron catalyst (tetrakis(4-sulfonic acid phenyl) porphyrin ferric chloride, FeTSPPCl) in the acid-producing phase reactor, add 1 mL of methanol, fully shake until completely dissolved, and pour Add 1.25 mL of 30% by mass hydrogen peroxide solution (the solution contains 0.375 mL of hydrogen peroxide), place in a constant temperature shaking incubator at 30° C. and shake for 3 hours to obtain a mixed solution.

[0039] S2, add 100mL fresh activated sludge (TSS=25.55g / L) to the acid production phase reactor in step S1, feed air from below the liquid level, to ensure that a certain amount of dissolved oxygen is contained in the acid production phase reactor , so as to effectively inhibit the growth of methanogenic bacteria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com