Treatment method for drilling mud cuttings in oil and gas fields

A treatment method, drilling mud technology, applied in sludge treatment, biological sludge treatment, immiscible solvent sludge treatment, etc., can solve the problems of non-environmental protection treatment costs, large soil damage, etc., to improve mud properties, improve Effect of Soil Aggregate Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Step 1, adding crushed straw (with a particle size of 5 mm to 50 mm) to the drilling mud produced on the drilling site, the mass ratio of the drilling mud to the straw is 1:0.05, and stirring evenly;

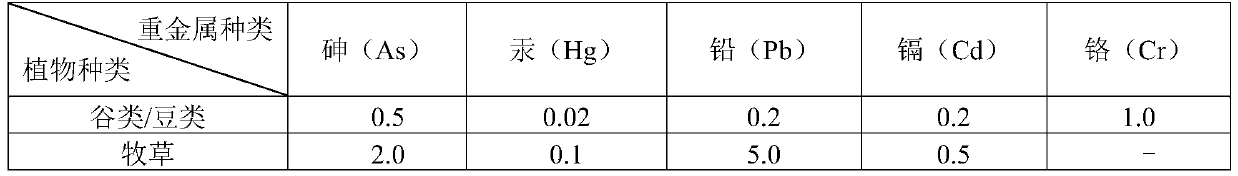

[0028] Step 2, adding humic acid to the drilling mud processed in step 1, the mass ratio of drilling mud and humic acid is 1:0.12, complexing the heavy metal ions in the drilling mud, the heavy metal ions are arsenic, mercury, One or more of lead, cadmium and chromium;

[0029] Step 3, adding microbial preparations to the drilling mud treated in step 2, the mass ratio of drilling mud and microbial preparations is 1:0.005, and the microbial preparations are Bacillus colloidus or Bacillus subtilis, that is, complete the treatment of drilling mud processing.

Embodiment 2

[0031] Step 1, adding crushed straw (with a particle size of 5 mm to 50 mm) to the drilling mud produced on the drilling site, the mass ratio of the drilling mud to the straw is 1:0.1, and stirring evenly;

[0032] Step 2, adding humic acid to the drilling mud processed in step 1, the mass ratio of drilling mud and humic acid is 1:0.1, complexing the heavy metal ions in the drilling mud, the heavy metal ions are arsenic, mercury, One or more of lead, cadmium and chromium;

[0033] Step 3, adding microbial preparations to the drilling mud treated in step 2, the mass ratio of drilling mud and microbial preparations is 1:0.008, and the microbial preparations are Bacillus colloidus or Bacillus subtilis, that is, complete the treatment of drilling mud processing.

Embodiment 3

[0035] Step 1, adding crushed straw (with a particle size of 5 mm to 50 mm) to the drilling mud produced on the drilling site, the mass ratio of drilling mud and straw is 1:0.2, and stirring evenly;

[0036] Step 2, adding humic acid to the drilling mud processed in step 1, the mass ratio of drilling mud and humic acid is 1:0.15, complexing the heavy metal ions in the drilling mud, the heavy metal ions are arsenic, mercury, One or more of lead, cadmium and chromium;

[0037] Step 3, adding microbial preparations to the drilling mud treated in step 2, the mass ratio of drilling mud and microbial preparations is 1:0.01, and the microbial preparations are Bacillus colioids or Bacillus subtilis, that is, complete the treatment of drilling mud processing.

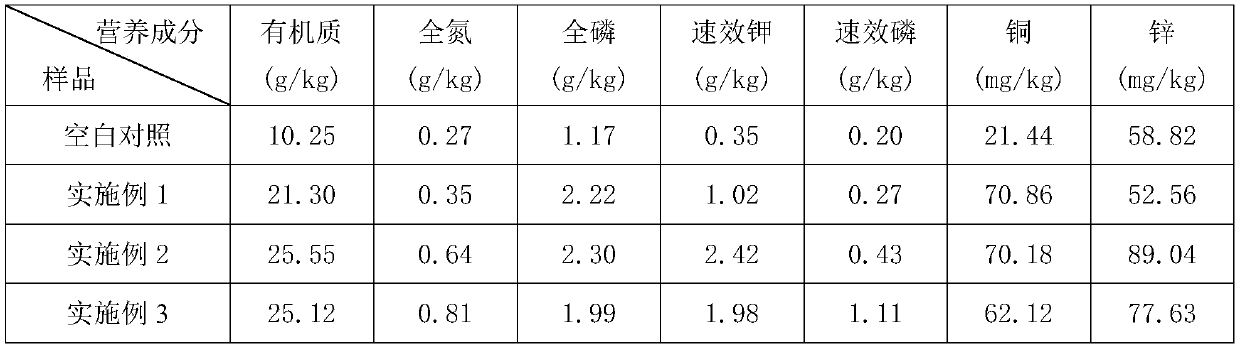

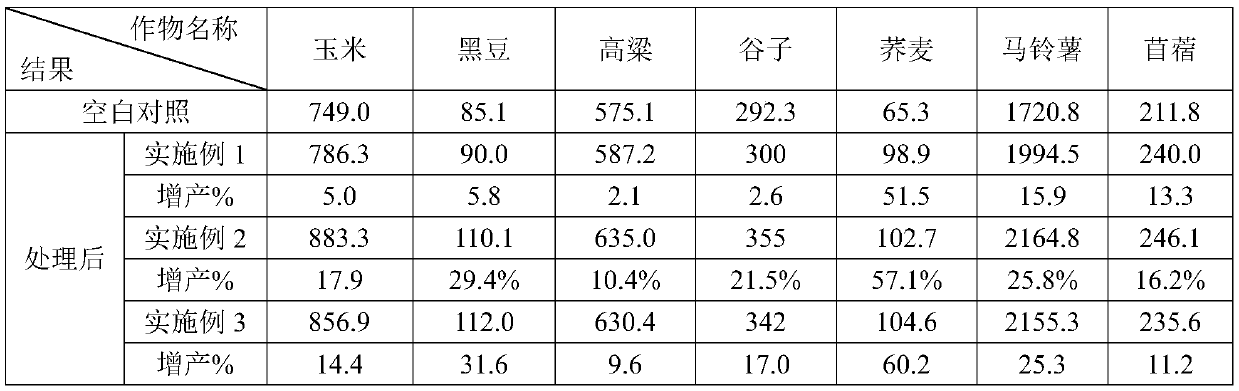

[0038] Above-mentioned 3 items all carry out drilling mud cuttings according to processing method of the present invention, the present invention is also provided with blank control, all in the test that Changqing Oilfield carr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com