Oily sludge treatment system based on ultrasonic waves and process thereof

A sludge treatment and ultrasonic technology, which is used in sludge treatment, water/sludge/sewage treatment, immiscible solvent sludge treatment, etc. problem, to achieve the effect of improving sludge dryness, reducing oil content and improving sludge dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

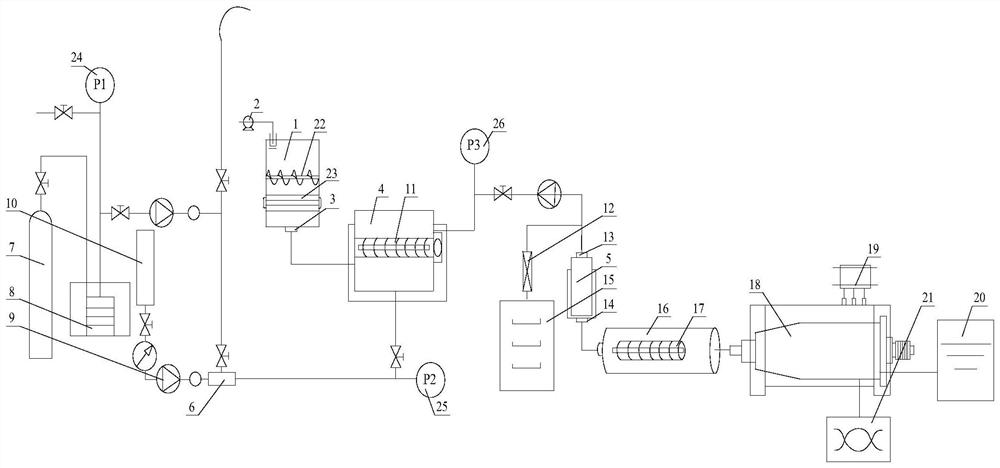

[0029] Below in conjunction with accompanying drawing and specific embodiment, the invention is further described:

[0030] Such as figure 1 As shown, an ultrasonic-based oily sludge treatment system includes sequentially connected pretreatment units, supercritical CO 2 Extraction unit, ultrasonic treatment unit and post-processing unit;

[0031] The pretreatment unit includes a pretreatment pool 1, the surface of the pretreatment pool 1 is provided with a drainage pump 2 for introducing oily sludge, and the bottom is provided with an outlet 3;

[0032] The supercritical CO 2 The extraction unit comprises an extraction reactor 4 connected to the pretreatment tank 1 at the side, and the bottom of the extraction reactor 4 is connected with supercritical CO 2 Generation module, the other side is connected with separation kettle 5, and the supercritical CO 2 The generation module consists of parallel supercritical CO 2 branch and carrier branch, the supercritical CO 2 Branch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com