Process for the Solvent Extraction for the Radiolysis and Dehalogenation of Halogenated Organic Compounds in Soils, Sludges, Sediments, and Slurries

a technology of solvent extraction and halogenation, which is applied in solvent extraction, separation processes, sludge treatment with immiscible liquids, etc., can solve the problems of high cost and public resistance, large environmental burden in water, sediment, soil and sediment, and large areas of soil and sediment contaminated with pcb's, etc., to achieve efficient radiolysis dehalogenation, high radiation dose uniformity, and high utilization efficiency of radiation source output power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

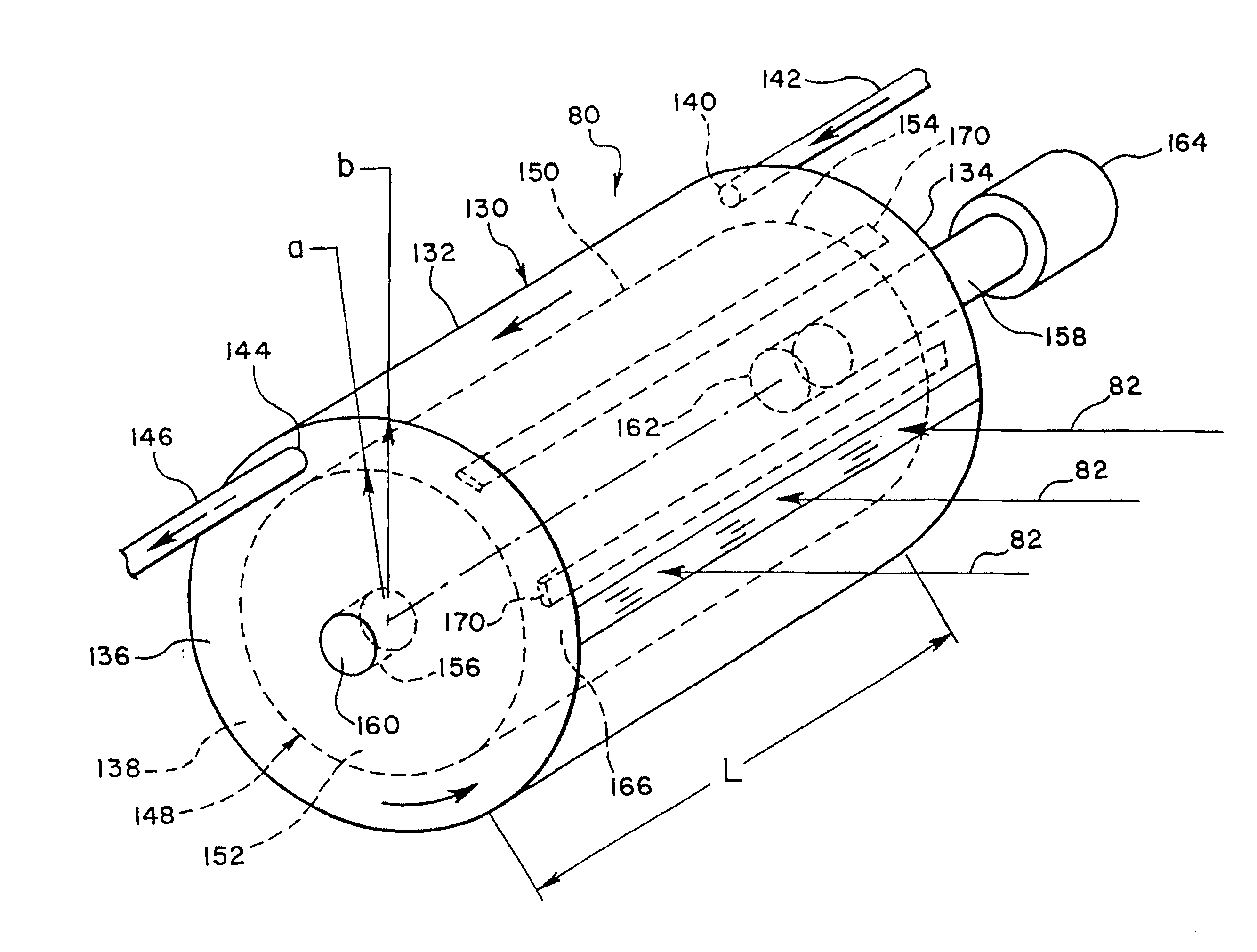

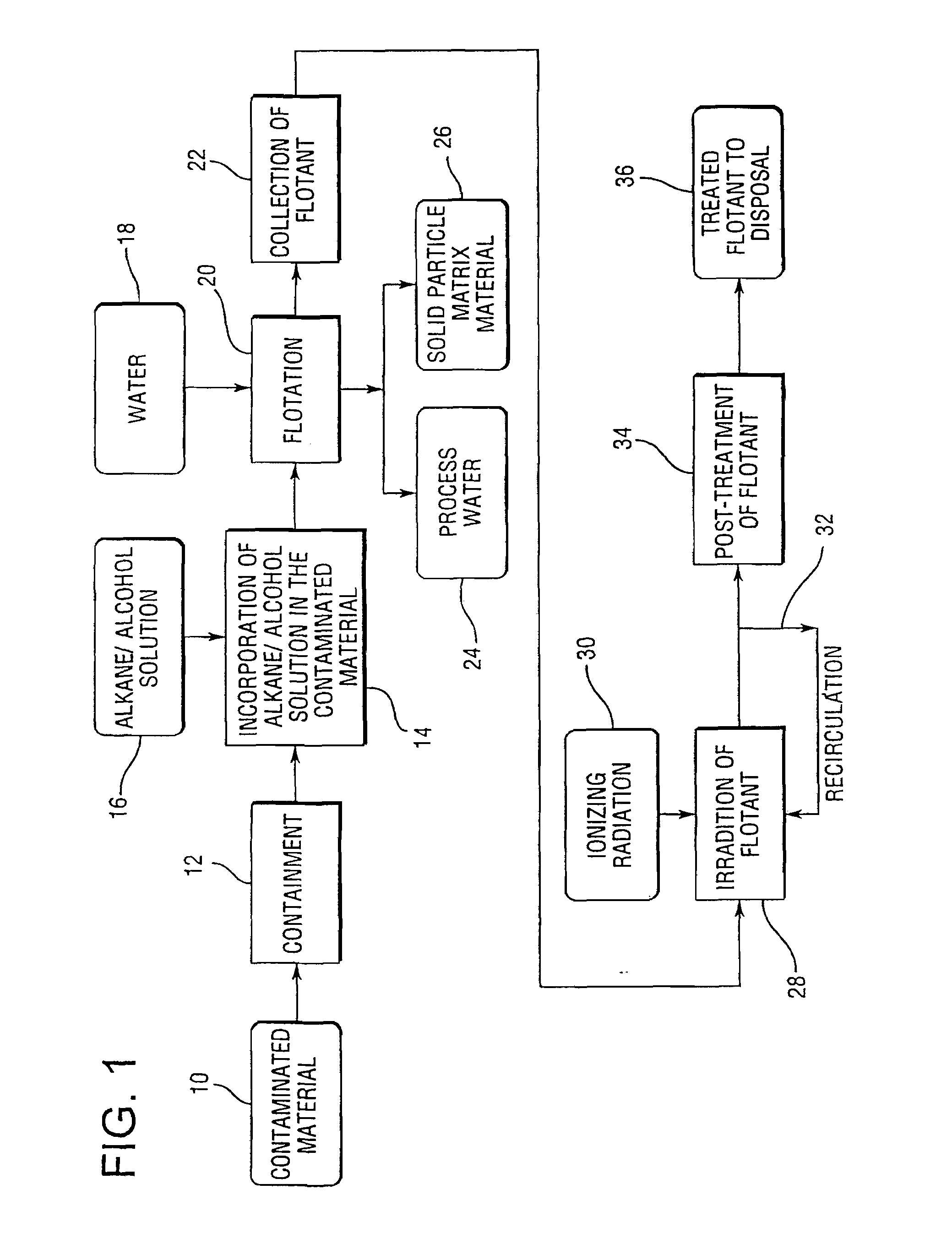

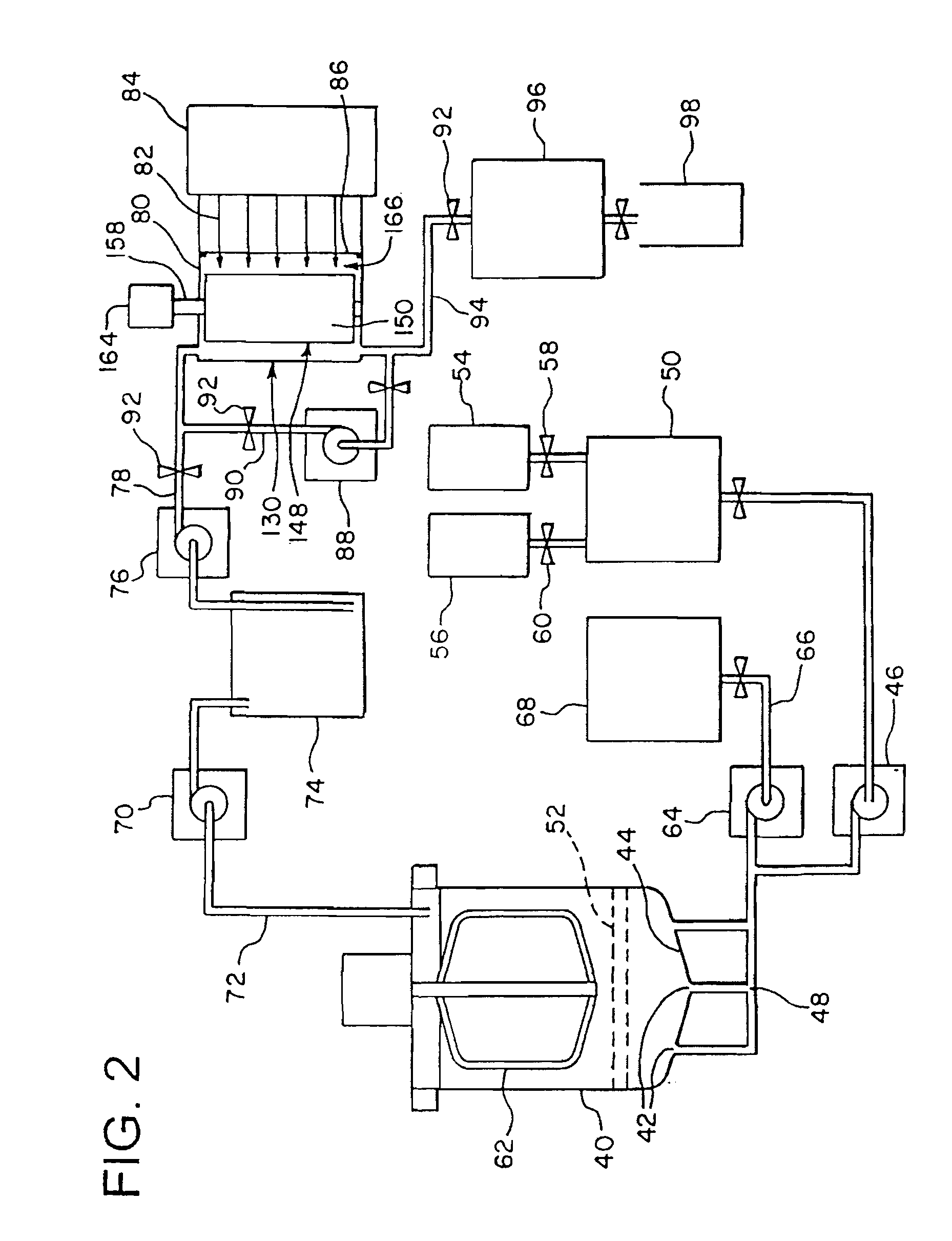

[0079] The following is a description of tests performed with Aroclor 1260 to determine the dose-constant for treatment of PCB by the flotation / extraction and radiolysis process. FIGS. 5-12 show dose-concentration curves for test samples 1-8. The reduction in concentration as dose increases can be fit to an exponential function and the dechlorination rate (dose constant) can be determined. The results of these tests are summarized in Table I. The dose-constant is given by: γ=1Dln(CoC)

TABLE ITest ResultsInitial Aroclor 1260Dose constantTest SampleConcentration(1 / (megarad))1. Spiked soil200 mg / kg0.011 + / − 0.0012. Spiked soil 58 mg / kg 0.016 + / − 0.00253. Flotant / Soltrol / t-butanol310 mg / liter0.413 + / − 0.1084. Flotant / Soltrol / isopropanol310 mg / liter (ppm) 0.44 + / − 0.0205. Flotant / Soltrol / t-butanol728 mg / liter0.242 + / − 0.0346. Flotant / Soltrol / isopropanol784 mg / liter0.176 + / − 0.0277. Spiked Soltrol / t-butanol232 mg / liter0.194 + / − 0.0478. Spiked Soltrol / isopropanol232 mg / liter0.202 + / − 0.0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentrations | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| average power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com