Assembly for producing radial tire belt parts

A technology for radial tires and belts, applied to tires, electric speed/acceleration control, and other household appliances, can solve problems such as deformation, difficulty in penetrating high-energy rays, and consistent performance of rubber-coated steel wire belts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

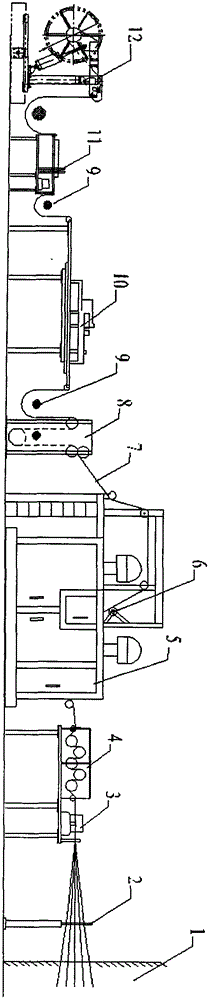

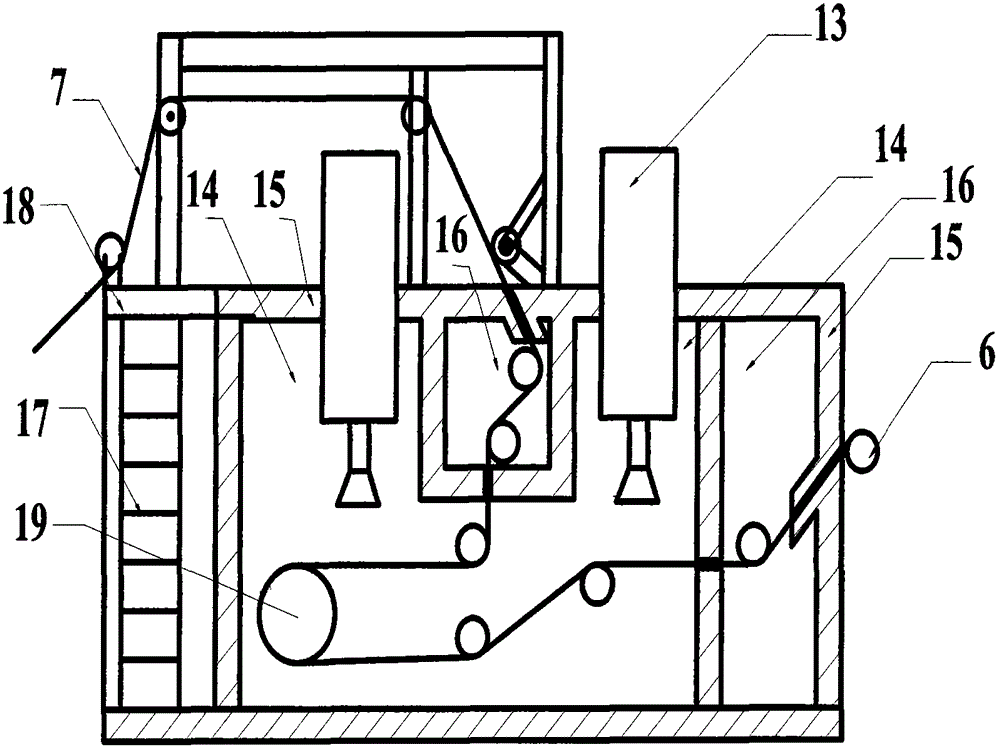

[0012] Attached below figure 1 And attached figure 2 Describe the present invention in detail, a device assembly for manufacturing radial tire belt components, including a spindle room 1, a warping frame 2, a cold feed extruder 3, a cooling device 4, a self-shielding irradiation device 5, a beam under Transmission device 6, cloth storage rack 8, photoelectric controller 9, cutting joint device 10, extrusion hemming device 11 and double-station coiling device 12, the characteristics of which are: the steel wire is unwound between the spindles 1 and maintains a constant tension The preliminary radial arrangement and arrangement of the steel wires are completed through the warping frame 2 to form a steel wire belt, which enters the cold feed extruder 3, and the rubber compound is covered around the steel wires in the cold feed extruder 3, and extruded Form a tire belt layer 7 of a flat steel wire belt with steel wire as the radial skeleton material and rubber compound as the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com