Treatment method of oily sludge

A sludge treatment and oil sludge technology, which is applied in the fields of sludge treatment, water/sludge/sewage treatment, immiscible solvent sludge treatment, etc. requirements and other issues, to achieve the effect of being suitable for large-scale promotion and application, saving resources, and using simple methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

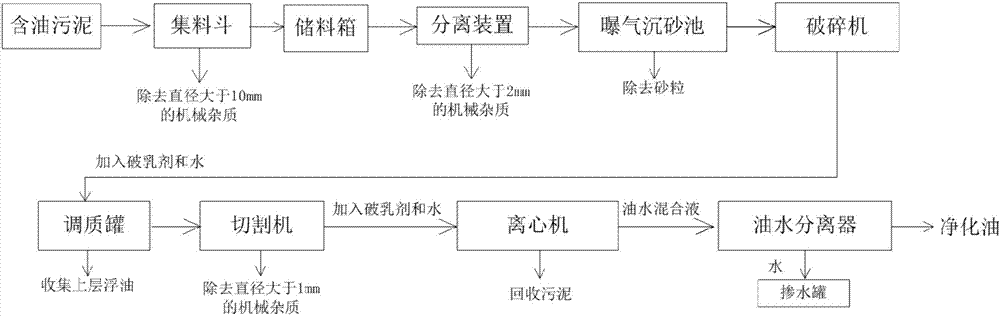

[0028] Embodiments of the present invention provide a method for treating oily sludge, the method comprising the following steps:

[0029] Remove mechanical impurities with a diameter greater than 2mm in oily sludge.

[0030] The oily sludge is aerated and gritted.

[0031] The oily sludge after sand settling treatment is crushed, and then demulsifier and water are added to carry out the first oil-water separation treatment to collect the upper oil slick from the oily sludge.

[0032] Cut, stir and squeeze the oily sludge from which the upper layer of oil has been removed, remove mechanical impurities with a diameter greater than 1mm in the oily sludge, add demulsifier and water again, and carry out the second oil-water separation treatment, and then remove the oily sludge from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com