Treatment technology for recovering and separating oily sludge

A technology for separation and treatment of oily sludge, applied in sludge treatment, immiscible solvent sludge treatment, water/sludge/sewage treatment, etc., can solve problems such as air pollution, large investment, and a large amount of dust, and achieve separation Fast speed and good separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

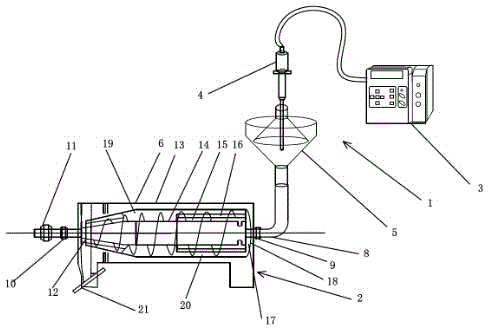

[0020] A recovery and separation treatment technology for oily sludge, the treatment technology adopts the following device, such as figure 1 As shown, the device includes an ultrasonic extractor 1 and a centrifugal separator 2, the ultrasonic extractor 1 includes a signal generator 3, an energy conversion instrument 4 and a mud hopper 5, the centrifugal separator 2 includes a main body 6, and an insulating layer is arranged inside the main body 6 19. The insulation layer 19 is located inside the inner wall of the main body 6. A heating device is provided inside the insulation layer 19. A housing 7 is provided outside the main body 6. The right end of the housing 7 is provided with a feed port 8 connected to the mud hopper 5. The feed port 8 The base is provided with a feed inlet bearing frame 9, and the left end of the housing 7 is provided with a mud discharge port bearing frame 10 and a differential gear 11 connected thereto. There is a mud discharge baffle 21; a drum 13 is...

Embodiment 2

[0023] Adopt the device of embodiment 1, the specific steps of this treatment technology are as follows: in every part of 100g, at first 50 parts of oily sludge, 50 parts of pH are 12 sodium hydroxide solution, 2.6 parts of active agent rhamnolipids are added In mud hopper 5, adopt ultrasonic extractor 1 to carry out mixed treatment under frequency 20KHz, processing time is 30min, then mixture enters centrifuge 2, and the rotating speed of spiral push rod 13 in centrifuge 2 is 4000r / min, The treatment time of the mixture in the centrifugal separator 2 is 20 minutes; and the temperature in the centrifugal separator 2 is controlled to be 50°C.

[0024] The separation recoveries of embodiment 1 and embodiment 2 are respectively 96% and 97%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com