Oil-field oil sludge factory-like comprehensive treatment system based on Internet of Things technology

An Internet of Things technology and comprehensive treatment technology, which is applied in the field of harmless treatment of waste oil sludge, can solve the problems of secondary pollution, less comprehensive utilization methods, and impact, and achieve the effect of improving efficiency and avoiding secondary wastewater discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

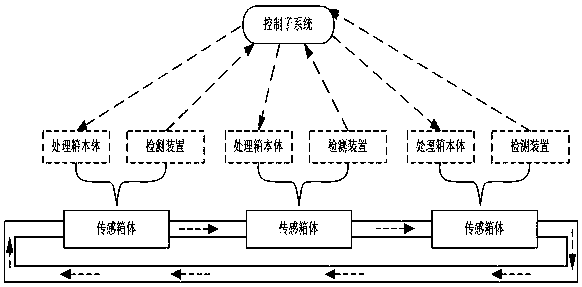

[0031] In order to solve the situation that in the traditional sludge treatment system, each treatment box body is guarded, observed and controlled by human beings, this embodiment provides a factory comprehensive treatment system for oilfield sludge based on Internet of Things technology, which includes: m sensing boxes and control subsystems, the sensing box includes: a processing box body, a detection device arranged in the processing box body, each processing box body is provided with a treatment device for treating sludge, The m detection devices communicate with the control subsystem respectively;

[0032] The detection device collects and sends the data of the sludge in the processing box body; the control subsystem receives and processes the data transmitted by the detection device, and controls the processing device to work;

[0033] The m treatment box bodies are connected sequentially, and the controller also controls the sludge in the first treatment box body to me...

Embodiment 2

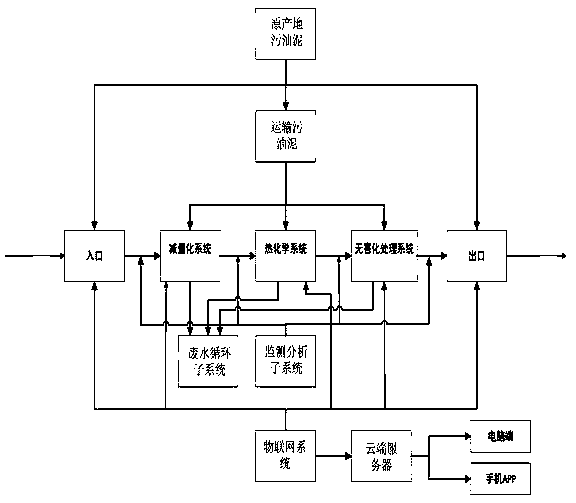

[0047] Such as figure 2 As shown, the waste water produced by the thermochemical separation system, reduction system, and harmless treatment system is also recycled to the first treatment tank body for secondary use, which avoids the discharge of secondary waste water and ensures that waste water does not leave the factory.

[0048] In this embodiment, a wastewater circulation pipeline is provided between the first treatment box body and the mth treatment box body, and a control valve is provided on the wastewater circulation pipeline. After the control subsystem controls the mth treatment device to stop working, Then control the control valve to open, so that the water treated by the mth treatment device enters the first treatment box body for recycling through the waste water circulation pipeline. There is a sludge circulation device between the first treatment box body and the m-th treatment box body. After the control subsystem controls the m-th treatment device to stop w...

Embodiment 3

[0055] The difference from Embodiment 1 and Embodiment 2 is that the comprehensive treatment system for oilfield sludge in this embodiment also includes an oil storage tank for storing separated oil, and a metering device is provided on the oil storage tank, and the metering device sends data to the cloud server Send oil metering information, the cloud server stores the capacity information of several oil tankers, the information of the tanker driver, the time information of the arrival and departure of the oil tanker, the cloud server controls the separation in the oil storage tank through the connection processing subsystem Oil is transported without interruption.

[0056] In this embodiment, the reasonable metering and transportation and connection processing system between tank trucks and workshops, the data involved such as time, source, quantity, content (the ratio of oil to water and solid), etc. will be input into the system platform based on the Internet of Things.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com