Oil-containing sludge cleaning agent, and cleaning method

A cleaning agent and sludge technology, which is applied in the field of new oily sludge cleaning agent and cleaning technology, can solve the problems of atmospheric environment damage, low efficiency, and large environmental pollution, so as to improve environmental friendliness, reduce use cost, and facilitate raw materials Easy to get effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

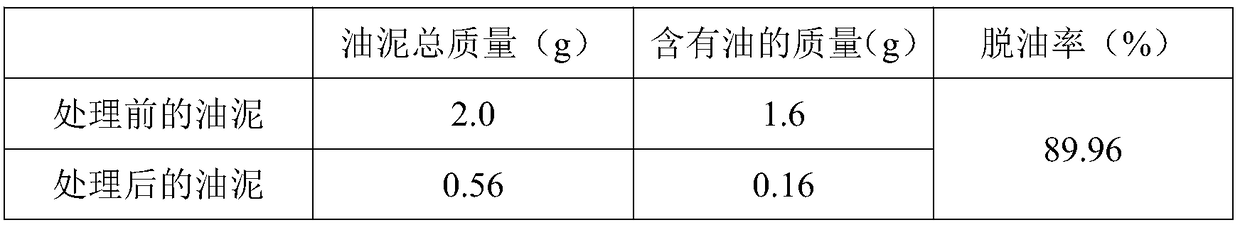

Embodiment 1

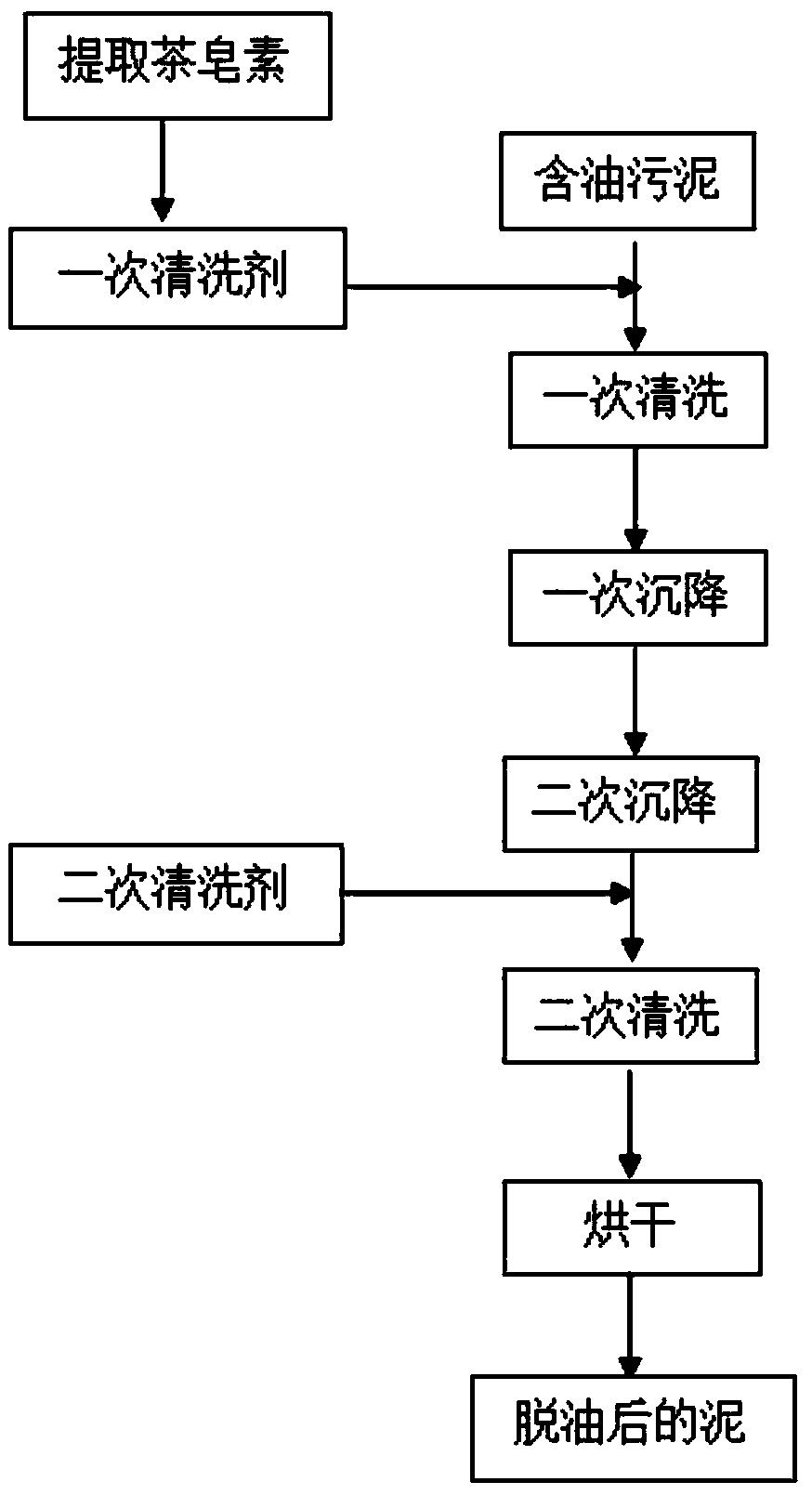

[0029] A method for cleaning oily sludge using the above cleaning agent, comprising the steps of:

[0030] Step S1, first extract tea saponin, the operation is as follows: put 20g of tea seed powder into a Soxhlet extractor, add 300ml of absolute ethanol, in order to prevent the tea seed powder from clogging the extraction tube, wrap the powder with filter paper. Then heat with an electric heating mantle and extract for 6-7 hours until the color of the solution in the round bottom flask changes from colorless to yellow; put the obtained yellow solution in an oven for drying, and grind the dried solid matter with a mortar , that is, tea saponin is obtained; the extraction time must be long, so that the tea saponin in the tea seed powder is fully dissolved in absolute ethanol, which is beneficial to the improvement of the cleaning effect. Then, configure a cleaning agent: dissolve 0.6g tea saponin, 0.3g sodium silicate, 0.05g sodium bicarbonate, 0.05g AEO (fatty alcohol polyoxye...

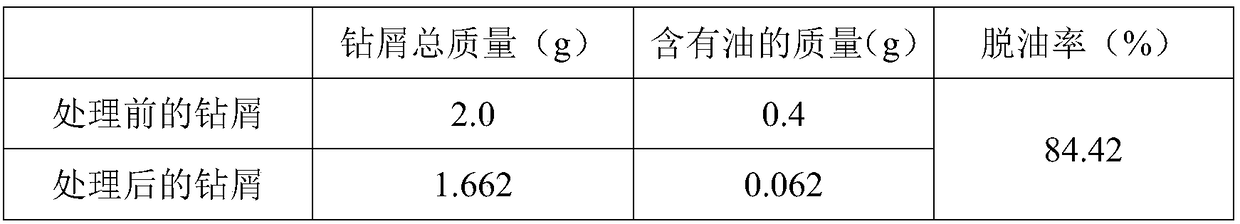

Embodiment 2

[0039] A method for cleaning oily sludge using the above cleaning agent, comprising the steps of:

[0040]Step S1, first extract tea saponin, the operation is as follows: put 20g of tea seed powder into a Soxhlet extractor, add 300ml of absolute ethanol, in order to prevent the tea seed powder from clogging the extraction tube, wrap the powder with filter paper. Then heat with an electric heating mantle and extract for 6-7 hours until the color of the solution in the round bottom flask changes from colorless to yellow; put the obtained yellow solution in an oven for drying, and grind the dried solid matter with a mortar , that is, tea saponin is obtained; the extraction time must be long, so that the tea saponin in the tea seed powder is fully dissolved in absolute ethanol, which is beneficial to the improvement of the cleaning effect. Then, configure a cleaning agent: dissolve 0.3g tea saponin, 0.15g sodium silicate, 0.025g sodium bicarbonate, 0.025g AEO (fatty alcohol polyox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com