Treatment method of oily sludge

A treatment method and sludge technology, applied in sludge treatment, water/sludge/sewage treatment, immiscible solvent sludge treatment, etc., can solve the problem of not being able to fully utilize the beneficial value of oily sludge and achieve full utilization Value, ease of control, effect of improving oil removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

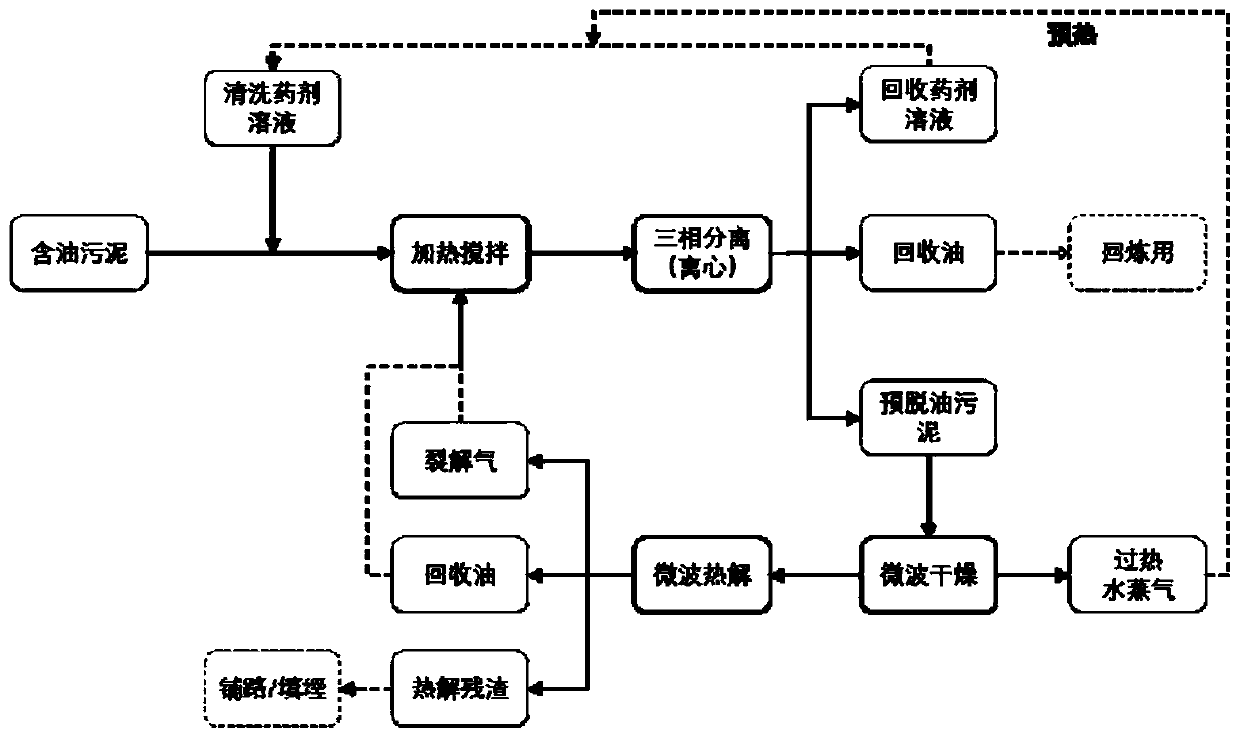

[0040] Such as figure 1 As shown, the treatment of oily sludge in an oilfield is as follows:

[0041] The water content of the oily sludge before treatment was 54wt%, the oil content was 26wt%, and the solid content was 20wt%.

[0042] The first step, the chemical heat detergent SDS, NP-10 and Na 2 SiO 3 Prepare a diluted solution of chemical heat cleaning agent with a concentration of 3wt% at a mass ratio of 1:1:1, mix the oily sludge and the chemical solution at a mass ratio of 1:4 and add them to the heating and stirring device.

[0043] The second step is to start heating, set the heating temperature to 80°C, and start stirring after the temperature reaches, set the stirring rate to 200r / min, and the stirring time to 50min, and carry out the chemical heat washing operation.

[0044] Step 3: After the chemical heat washing is completed, the material is taken out and sent to the centrifuge device. The centrifuged material will be layered, which is the upper layer of oil s...

Embodiment 2

[0047] The first step, the chemical heat detergent AEO-9, LAS and Na 2 SiO 3 Prepare a diluted solution of 3 wt% chemical heat cleaning agent at a mass ratio of 1:1:1, mix oily sludge (same source as in Example 1) and agent solution at a mass ratio of 1:4 and add to the heating and stirring device.

[0048] The second step is to start heating, set the heating temperature to 80°C, and start stirring after the temperature reaches, set the stirring rate to 200r / min, and the stirring time to 50min, and carry out the chemical heat washing operation.

[0049] Step 3: After the chemical heat washing is completed, the material is taken out and sent to the centrifuge device. The centrifuged material will be layered, which is the upper layer of oil slick, the middle layer of sewage, and the lower layer of sludge. Cutting and separation are carried out separately, the upper layer of slick oil and the middle layer of sewage are recovered, and the lower layer of sludge is treated as pre-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com