Separating agent and method for separating petroleum from petroleum sludge

A separation agent, petroleum technology, applied in chemical instruments and methods, sludge treatment, immiscible solvent sludge treatment, etc., can solve the problems of high treatment cost, waste of resources, long treatment period, etc. Inexpensive and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

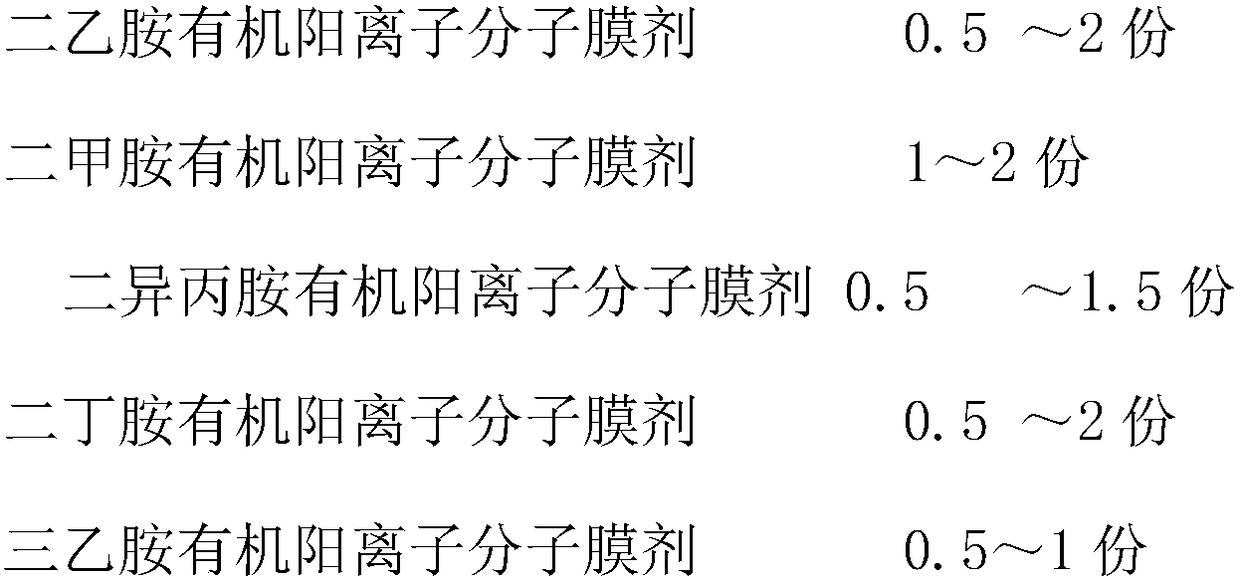

[0030] Taking the preparation of 100g of oily sludge thermochemical separation agent as an example, the raw materials used and their mass ratios are as follows:

[0031] Diethylamine Organic Cationic Molecular Film Agent 20g

[0032] Dimethylamine Organic Cationic Molecular Film Agent 20g

[0033] Diisopropylamine Organic Cationic Molecular Film Agent 20g

[0034] Dibutylamine Organic Cationic Molecular Film Agent 20g

[0035] Triethylamine Organic Cationic Molecular Film Agent 20g

[0036] Above-mentioned diethylamine organic cationic molecular membrane agent is prepared by the following method

[0037] In a nitrogen atmosphere, add 69.4g of 50% epichlorohydrin aqueous solution into a 250mL three-necked flask, place the three-necked flask in a water bath, control the temperature of the water bath to 0°C, and add 0.424g of 50% sodium sulfite Aqueous solution and 0.424g mass fraction are 50% potassium persulfate aqueous solution, stir, use constant pressure funnel to dropwi...

Embodiment 2

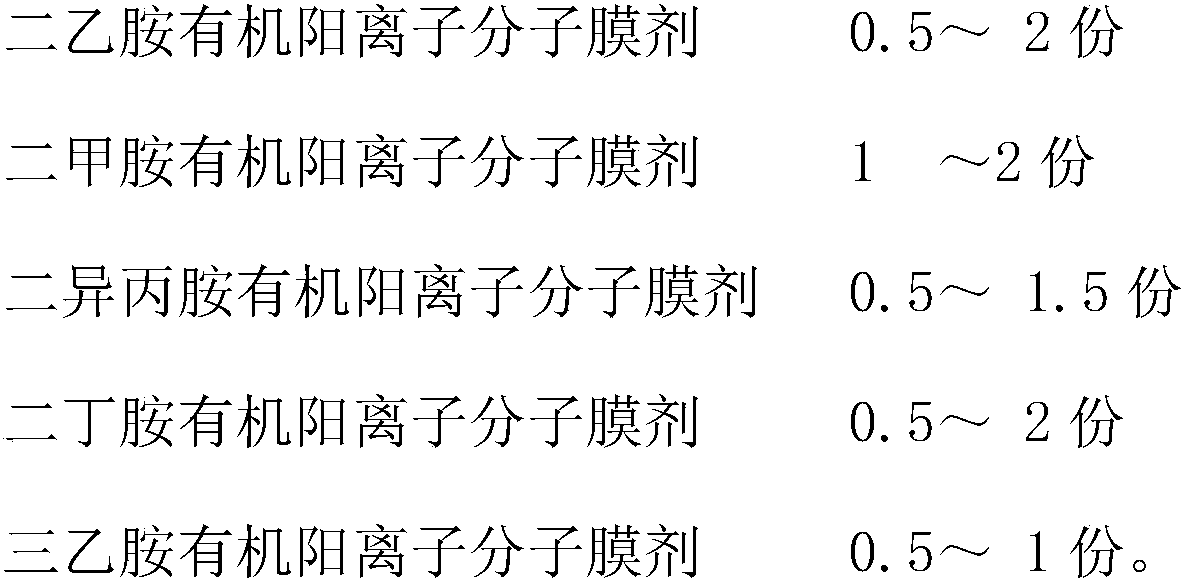

[0041] Taking the preparation of 100g of oily sludge thermochemical separation agent as an example, the raw materials used and their mass ratios are as follows:

[0042] Diethylamine Organic Cationic Molecular Film Agent 17.65g

[0043] Dimethylamine Organic Cationic Molecular Film Agent 29.40g

[0044] Diisopropylamine Organic Cationic Molecular Film Agent 17.65g

[0045] Dibutylamine Organic Cationic Molecular Film Agent 17.65g

[0046] Triethylamine Organic Cationic Molecular Film Agent 17.65g

[0047] The above-mentioned thermochemical separation agent for preparing oily sludge is made from the following raw materials in proportions by mass:

[0048] Diethylamine organic cationic molecular film agent 0.6 parts

[0049] Dimethylamine organic cationic molecular film agent 1 part

[0050] Diisopropylamine organic cationic molecular film agent 0.6 parts

[0051] Dibutylamine organic cationic molecular film agent 0.6 parts

[0052] Triethylamine organic cationic molecula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com