Prepn process and apparatus of polyurethane fiber

A technology of polyurethane fiber and prepolymerization, applied in the direction of single-component polyurethane artificial filament, etc., can solve the problems of increasing cost, process time and difficulty in realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

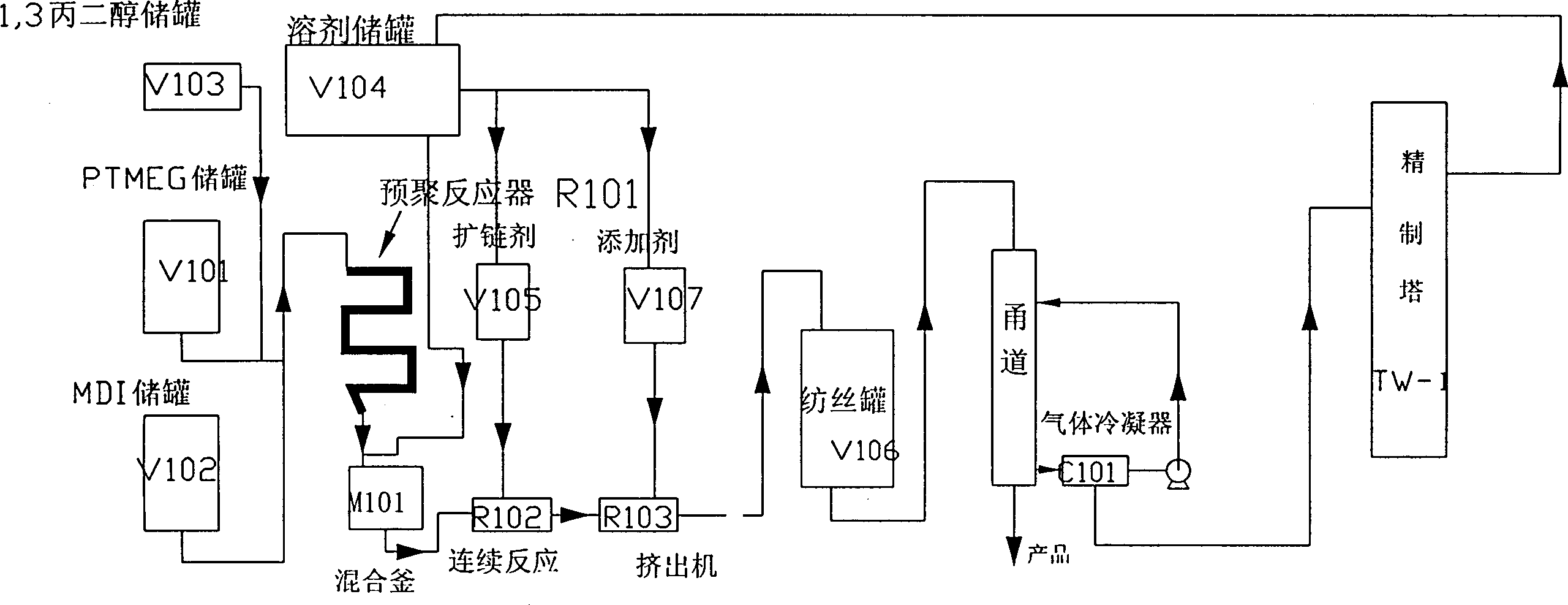

Image

Examples

experiment example 2

[0077] The experiment was carried out in the experimental device B, with PTMEG40.8kg, MDI7.2kg, 1,3 propylene glycol 0.08kg mixed evenly. The reaction temperature is 70°C, the reaction time is 120min, and a prepolymer is generated, and the prepolymer discharged from the prepolymerization reactor is placed in N 2 In the protected container, it takes 245 minutes to cool the prepolymer to 40-45°C by passing water at 5°C. Add 73.2kg of DMF, stir evenly and enter the continuous polymerization reactor with 122.08kg. Prepare 1.096g of ethylenediamine, diethylamine, and propylenediamine in a volume ratio of 70:10:20, and add 32.99kg of DMF. Add 152.75 kg of this mixed solution to the polymerization reactor simultaneously with the prepolymer solution. Cooling water at 5° C. is passed through the jacket of the reactor to maintain the temperature at about 20° C. during the reaction. After reacting for one hour, 152.75 kg of the reaction solution entered the screw mixer, and at the same...

experiment example 4

[0088] The experiment was carried out in the experimental device B, with PTMEG40.8kg, MDI7.2kg, and n-butanol 0.08kg mixed evenly. The reaction temperature is 70°C, the reaction time is 120min, and a prepolymer is generated, and the prepolymer discharged from the prepolymerization reactor is placed in N 2 In the protected container, it takes 244 minutes to cool the prepolymer to 40-45° C. with 5° C. water. Add 35.48kg of pyrrolidone, stir evenly and enter the continuous polymerization reactor with 84.36kg. Configure 1.096g of ethylenediamine, diethylamine, and propylenediamine in a volume ratio of 70:10:20, and add 14.61kg of pyrrolidone. Add 99.27 kg of this mixed solution to the polymerization reactor at the same time as the prepolymer solution. Cooling water at 5° C. is passed through the jacket of the reactor to maintain the temperature at about 20° C. during the reaction. After reacting for one hour, 99.27 kg of the reaction solution entered the screw mixer, and at the ...

experiment example 5

[0094] Experimental Example 5 The mixed diamine is composed of ethylenediamine, dibutylamine and propylenediamine, and its volume ratio is 70:10:20;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com