Silver and silver alloy passivation process

A technology of silver alloy and process, which is applied in the field of passivation process of silver and silver alloy, can solve the problems of complex coating process and non-environmental protection, and achieve the effect of strong operability and good anti-corrosion protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

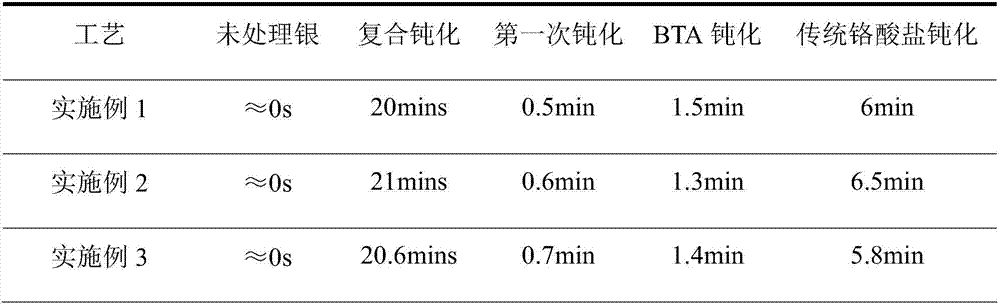

Embodiment 1

[0034] A passivation process for silver and silver alloys, comprising the steps of:

[0035] 1) Silver or silver alloy surface degreasing treatment: place silver or silver alloy in acetone for 30 minutes of ultrasonic treatment, and then dry it with a hair dryer for use;

[0036] 2) Primary passivation treatment: immerse the clean silver or silver alloy treated in step 1) into 6-N,N-dibutylamine-1,3,5-triazine-2,4- In the thiol solution, passivate the self-assembly at 35°C for 20 minutes, take it out, and air dry;

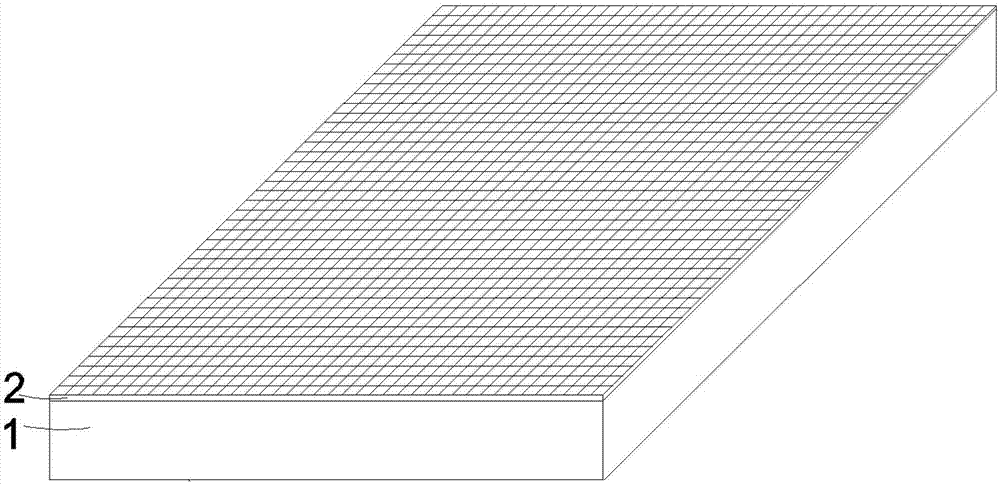

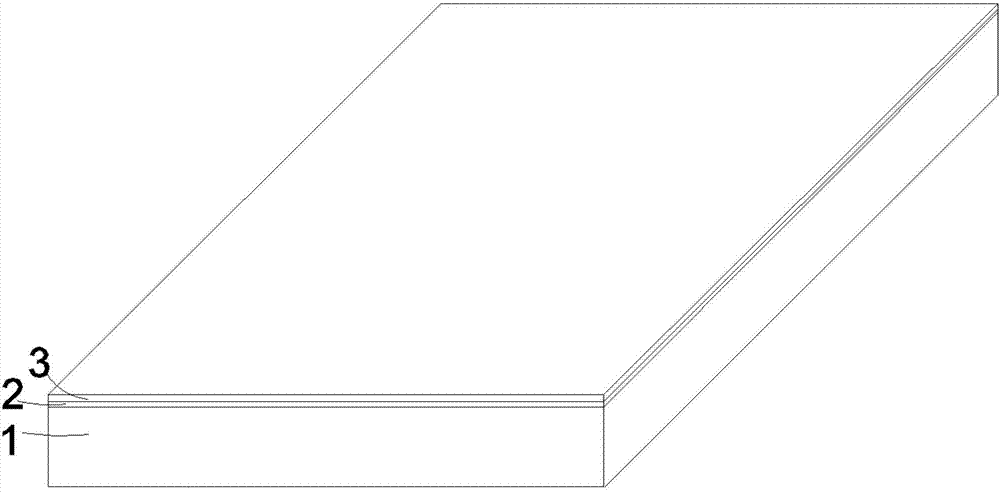

[0037] 3) Curing treatment: place the silver or silver alloy treated in step 2) at 150°C for 15 minutes, then wash and dry with deionized water to obtain a network structure film tightly combined with silver or silver alloy, specifically as figure 1 shown;

[0038] 4) Secondary passivation treatment: the silver or silver alloy after step 3) is placed in isopropanol as a solvent, and stearyl mercaptan and phenylacryltriazole are a solute solution for self-assembly...

Embodiment 2

[0042] A passivation process for silver and silver alloys, comprising the steps of:

[0043] 1) Silver or silver alloy surface degreasing treatment: place silver or silver alloy in acetone for 20 minutes of ultrasonic treatment, and then dry it with a hair dryer for use;

[0044] 2) Primary passivation treatment: immerse the clean silver or silver alloy treated in step 1) into 6-N,N-dibutylamine-1,3,5-triazine-2,4- In the thiol solution, passivate the self-assembly at 50°C for 50 minutes, take it out, and air dry;

[0045] 3) Curing treatment: place the silver or silver alloy treated in step 2) at 160° C. for 15 minutes, then wash and dry with deionized water to obtain a network structure film tightly combined with silver or silver alloy;

[0046] 4) Secondary passivation treatment: the silver or silver alloy after step 3) is placed in isopropanol as a solvent, and stearyl mercaptan and phenylacryltriazole are a solute solution for self-assembly processing, wherein octadecylt...

Embodiment 3

[0050] A passivation process for silver and silver alloys, comprising the steps of:

[0051] 1) Silver or silver alloy surface degreasing treatment: place silver or silver alloy in acetone for 20 minutes of ultrasonic treatment, and then dry it with a hair dryer for use;

[0052] 2) Primary passivation treatment: immerse the clean silver or silver alloy treated in step 1) into 6-N,N-dibutylamine-1,3,5-triazine-2,4- In the thiol solution, passivate the self-assembly at 40°C for 20 minutes, take it out, and air dry;

[0053] 3) Curing treatment: place the silver or silver alloy treated in step 2) at 120° C. for 20 minutes, then wash and dry with deionized water to obtain a network structure film tightly combined with silver or silver alloy;

[0054] 4) Secondary passivation treatment: the silver or silver alloy after step 3) is placed in isopropanol as a solvent, and stearyl mercaptan and phenylacryltriazole are a solute solution for self-assembly processing, wherein octadecylthi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com