Waterborne polyurethane industrial paint and preparation method thereof

A technology of water-based polyurethane and industrial paint, which is applied in paints containing biocide, anti-fouling/underwater coatings, coatings, etc., can solve the problems of low-temperature toughness, water resistance and pollution resistance of water-based polyurethane industrial paint films, and achieve Short curing time, fine and smooth paint film, suitable for popularization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

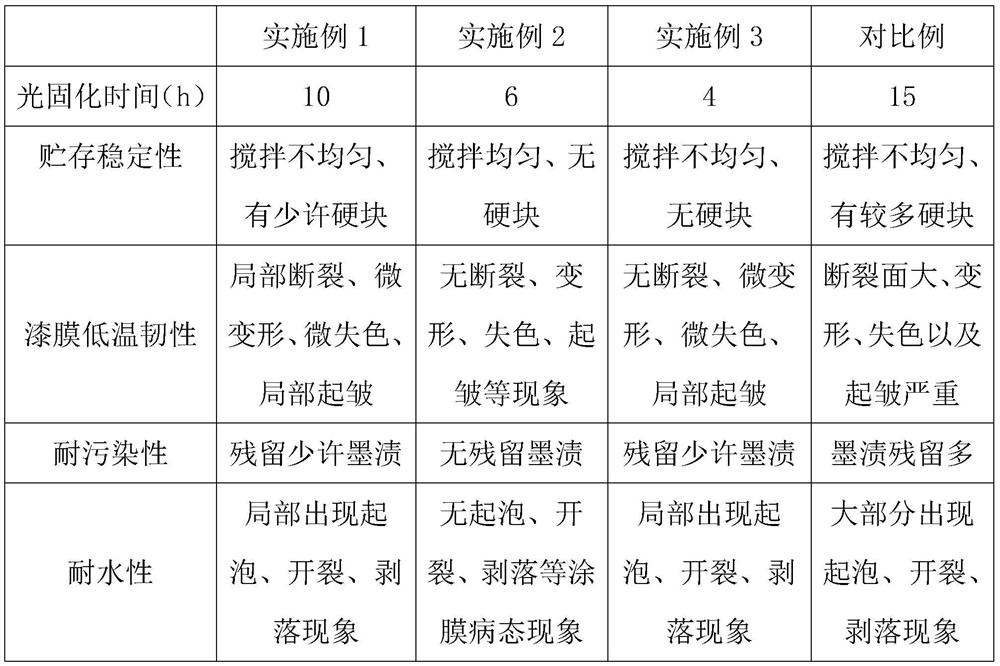

Examples

Embodiment 1

[0024] The invention provides a water-based polyurethane industrial paint. The preparation raw materials include the following components in parts by weight: 5 parts of polyether glycol, 3 parts of castor oil, 8 parts of isophorone diisocyanate (IPDI), dilauric acid 10 parts of dibutyltin (DBTDL), 0.5 parts of 1,4-butanediol (BDO), 1 part of dimethylol propionic acid (DMPA), 2 parts of epoxy resin, 1 part of trimethylolpropane (TMP), 25 parts of methyl methacrylate (MMA), 1 part of triethylamine, 1 part of ethylenediamine, 0.8 part of photoinitiator, 0.5 part of film-forming aid, 0.3 part of leveling agent, 0.3 part of thickener and appropriate amount of external agent, an appropriate amount of di-n-butylamine and a sufficient amount of dry nitrogen.

[0025] Further, the above-mentioned polyether glycol, castor oil, isophorone diisocyanate and dibutyltin dilaurate all need to undergo dehydration treatment.

[0026] Further, the above-mentioned triethylamine and ethylenediami...

Embodiment 2

[0036]The invention provides a waterborne polyurethane industrial paint. The raw materials for preparation include the following components in parts by weight: 7 parts of polyether glycol, 4 parts of castor oil, 12 parts of isophorone diisocyanate (IPDI), dilauric acid 12 parts of dibutyltin (DBTDL), 1 part of 1,4-butanediol (BDO), 2 parts of dimethylol propionic acid (DMPA), 3 parts of epoxy resin, 1.6 parts of trimethylolpropane (TMP), 34 parts of methyl methacrylate (MMA), 1.5 parts of triethylamine, 1.5 parts of ethylenediamine, 1 part of photoinitiator, 0.8 part of film-forming aid, 0.4 part of leveling agent, 0.5 part of thickener and appropriate amount of external agent, an appropriate amount of di-n-butylamine and a sufficient amount of dry nitrogen.

[0037] Further, the above-mentioned polyether glycol, castor oil, isophorone diisocyanate and dibutyltin dilaurate all need to undergo dehydration treatment.

[0038] Further, the above-mentioned triethylamine and ethyl...

Embodiment 3

[0048] The invention provides a water-based polyurethane industrial paint. The raw materials for preparation include the following components in parts by weight: 8 parts of polyether glycol, 5 parts of castor oil, 15 parts of isophorone diisocyanate (IPDI), dilauric acid 15 parts of dibutyltin (DBTDL), 1.5 parts of 1,4-butanediol (BDO), 3 parts of dimethylol propionic acid (DMPA), 4 parts of epoxy resin, 2 parts of trimethylolpropane (TMP), 40 parts of methyl methacrylate (MMA), 2 parts of triethylamine, 2 parts of ethylenediamine, 1.2 parts of photoinitiator, 1 part of film-forming aid, 0.6 part of leveling agent, 0.8 part of thickener and appropriate amount of external agent, an appropriate amount of di-n-butylamine and a sufficient amount of dry nitrogen.

[0049] Further, the above-mentioned polyether glycol, castor oil, isophorone diisocyanate and dibutyltin dilaurate all need to undergo dehydration treatment.

[0050] Further, the above-mentioned triethylamine and ethyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com