Method for combining tributylamine and used catalyst

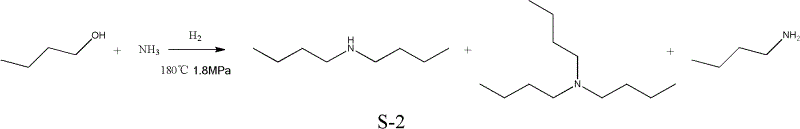

A technology of tri-n-butylamine and n-butylamine, applied in the field of organic compound synthesis, can solve problems such as being unsuitable for large-scale industrial production, unable to realize continuous production, expensive catalyst, etc., and achieve good mechanical strength and stability, The effect of easy control of the reaction and suitable reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

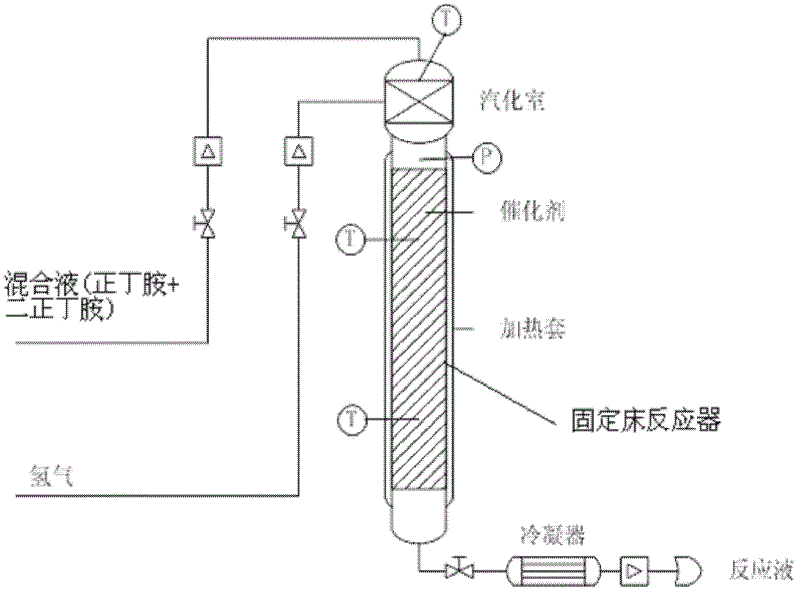

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, a kind of loaded catalyst that is used to prepare tri-n-butylamine, preparation process is as follows:

[0050] 1), initial roasting:

[0051] Gamma-alumina (γ-Al 2 o 3 ) at a temperature of 700°C to 800°C for 4 hours, and naturally cooled to room temperature to obtain the calcined γ-Al 2 o 3 ;

[0052] After testing: after roasting, the specific surface area of γ-alumina is 170-180m 2 g -1 , the pore size is 16.5-17.2nm; the particle diameter remains unchanged.

[0053] 2), the roasted γ-Al obtained in step 1) 2 o 3 Immerse in water for at least 36 hours, and then measure the volume of water reduction, so as to obtain the γ-Al after calcination 2 o 3 The pore volume density is about 0.9ml / g;

[0054] 3), dipping:

[0055] 7.44gNi(NO 3 ) 2 ·6H 2 O, 4.54g Cu(NO 3 ) 2 ·3H 2 O, 0.72gFe(NO 3 ) 3 9H 2 O and 0.94gPt(NO 3 ) 2 Dilute the volume to 6.3ml with water (for example, distilled water) to obtain an impregnating solution, and roast...

Embodiment 2

[0059] Embodiment 2, a kind of supported catalyst for preparing tri-n-butylamine, preparation process is as follows:

[0060] Step 3) Change to the following:

[0061] 3), 8.43gNi(NO 3 ) 2 ·6H 2 O, 3.97g Cu(NO 3 ) 2 ·3H 2 O, 0.65gFe(NO 3 ) 3 9H 2 O and 1.12gPt(NO 3 ) 2 Dilute the volume to 6.3ml with water to obtain the impregnating solution, then put in 7.1g of calcined γ-alumina (specific surface area 170-180m 2 g -1 ) to fully mix and impregnate until the impregnating solution is roasted and the γ-Al 2 o 3 Absorbs completely.

[0062] Step 1), 2) and 4) are the same as in Example 1.

[0063] The supported catalyst contains Ni: 17%; Cu: 10.5%; Fe: 0.9%; Pt: 0.6%. The % is by weight.

Embodiment 3

[0064] Embodiment 3, a kind of loaded catalyst for preparing tri-n-butylamine, preparation process is as follows:

[0065] Step 3) Change to the following:

[0066] 3), 9.42gNi(NO 3 ) 2 ·6H 2 O, 3.40g Cu(NO 3 ) 2 ·3H 2 O, 0.58gFe(NO 3 ) 3 9H 2 O and 1.31gPt(NO 3 ) 2 Dilute to 6.3ml with water to obtain an impregnating solution, then add 7.1g of roasted γ-Al 2 o 3 (specific surface area 170-180m 2 g -1 ) to fully mix and impregnate until the impregnating solution is roasted and the γ-Al 2 o 3 Absorbs completely.

[0067] Step 1), 2) and 4) are the same as in Example 1.

[0068] The supported catalyst contains Ni: 19%; Cu: 9%; Fe: 0.8%; Pt: 0.7%. The % is by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com